Cold Bonding Rubber Conveyor Belt Replacement at Chan May Port – Vietnam Shiprepair

When uptime and safety matter most, Vietnam Shiprepair delivers.

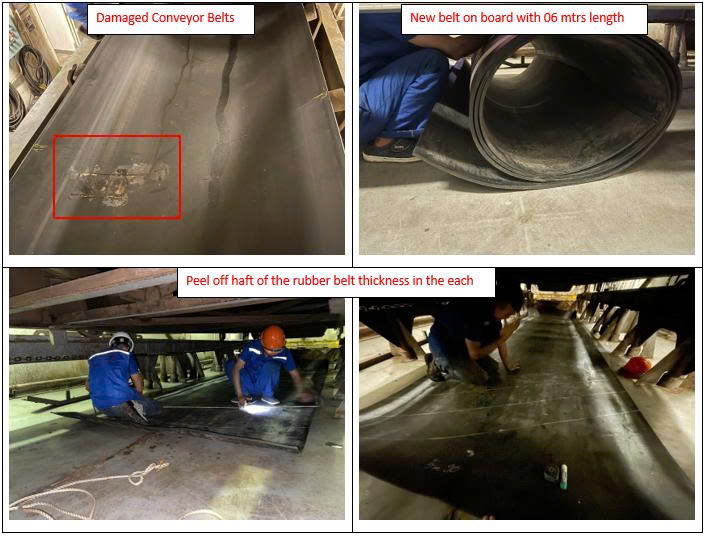

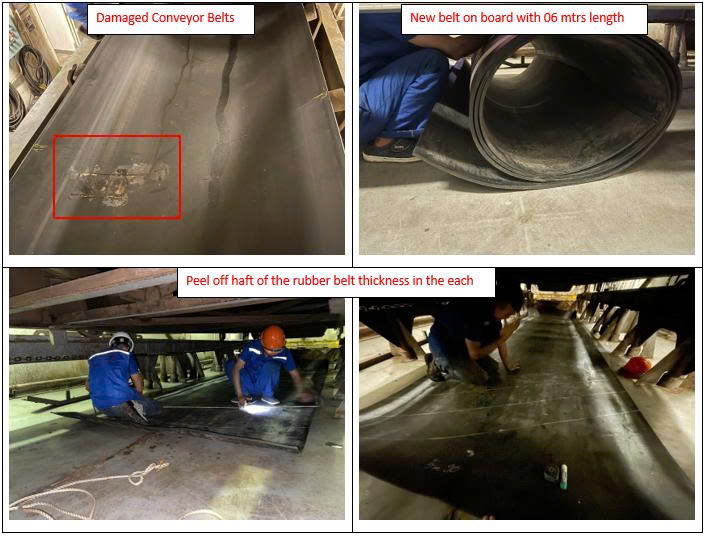

On November 13, 2025, our certified technicians successfully completed a Cold Bonding Rubber Conveyor Belt Replacement for a wood chip carrier at Chan May Port, ensuring seamless cargo handling without disrupting the vessel’s schedule.

We provide professional Marine Conveyor Belt Repair and onboard belt maintenance for wood chip carriers at all major ports and anchorages across Vietnam, including Nghi Son, Vung Tau, Ho Chi Minh City, and Chan May. All work strictly follows IACS and IMO standards for marine safety and compliance.

Why Cold Bonding Rubber Conveyor Belts Matter

Why Cold Bonding Rubber Conveyor Belts Matter

Rubber conveyor belts are essential for wood chip carriers, enabling continuous, efficient, and safe cargo transfer.

A worn or damaged conveyor belt can cause:

-

Slower cargo movement and potential spills

-

Unsafe conditions for personnel

-

Delays at port and non-compliance with IACS/IMO regulations

With Cold Bonding, Vietnam Shiprepair restores the belt’s strength and reliability without using heat, making it ideal for confined spaces like forepeak tanks or covered deck conveyors.

Step-by-Step: Cold Bonding Rubber Conveyor Belt Replacement at Chan May Port

Material Selection

We use IMO- and IACS-approved rubber belts, reinforced with EP fabric or steel cord. The adhesives are marine-grade cold bonding compounds, providing high tensile strength and long-term wear resistance.

Safe Removal of Worn Belt

Technicians lock out and tag out all drive systems. The old belt is cut into sections, removed safely, and disposed of properly.

Cold Bonding Installation

-

Prepare belt ends: clean, buff, and degrease

-

Apply adhesive layers: 2–3 coats, allowing curing between layers

-

Press belt ends together using mechanical rollers or clamps for uniform adhesion and precise alignment

-

Curing period: adhesive sets at ambient temperature, typically 18-20 hours

Cold bonding avoids heat, making it safe for confined or sensitive areas while achieving a seamless, strong joint.

Testing & Commissioning

After curing, belts are tested:

-

No-load run to verify alignment

-

Load simulation to confirm tension and smooth cargo flow

-

Final inspection ensures tracking and belt integrity

The conveyor system is returned to full operational service only after passing all checks.

Minimizing Downtime – Maximizing Efficiency

Minimizing Downtime – Maximizing Efficiency

Every hour in port counts.

Our mobile repair teams replace belts quickly without delaying cargo operations. Cold Bonding allows work in tight spaces, reducing risk and ensuring uninterrupted vessel turnaround.

Certified Quality – IACS & IMO Compliance

All Vietnam Shiprepair technicians are IACS-certified.

Every job includes:

-

Belt specification and batch documentation

-

Cold bonding log (adhesive type, layer count, curing time)

-

Inspection checklist and compliance verification

This guarantees a traceable, class-approved repair process every time.

Why Choose Vietnam Shiprepair

-

20+ years of experience in marine repair and bulk cargo systems

-

IACS/IMO certified technicians

-

Cold bonding expertise for safe and durable splicing

-

Fast, mobile response across all Vietnamese ports

-

Cost-effective solutions minimizing downtime

With Vietnam Shiprepair, you get reliable, long-term solutions for Marine Conveyor Belt Maintenance.

Contact Vietnam Shiprepair

Head Office: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam

Mobile/WhatsApp/WeChat: +84 869 677 769

Email: contact@vietnamshiprepair.net

Website: https://vietnamshiprepair.net

Why Cold Bonding Rubber Conveyor Belts Matter

Why Cold Bonding Rubber Conveyor Belts Matter Minimizing Downtime – Maximizing Efficiency

Minimizing Downtime – Maximizing Efficiency