M.E L.O Pump Repairs for Container Ship at Vung Tau Port – Performed by VietNam ShipRepair

Ensuring the efficient operation of a container ship requires precise attention to its main engine components. One of the most vital among these is the Main Engine Lubrication Oil Pump (M.E L.O Pump). At Vung Tau Port, VietNam ShipRepair recently completed a comprehensive M.E L.O Pump Repairs/Main Engine Service, which included replacing the Upper Shaft and Bearing Housing completed set of a container ship’s L.O pump.

This essential service is available not only in Vung Tau but also across all ports and anchorages in Vietnam, including Da Nang, Nghi Son, Ho Chi Minh City, and others. With a professional team and strict adherence to international standards such as IMO and IACS, VietNam ShipRepair delivers dependable service and complete peace of mind.

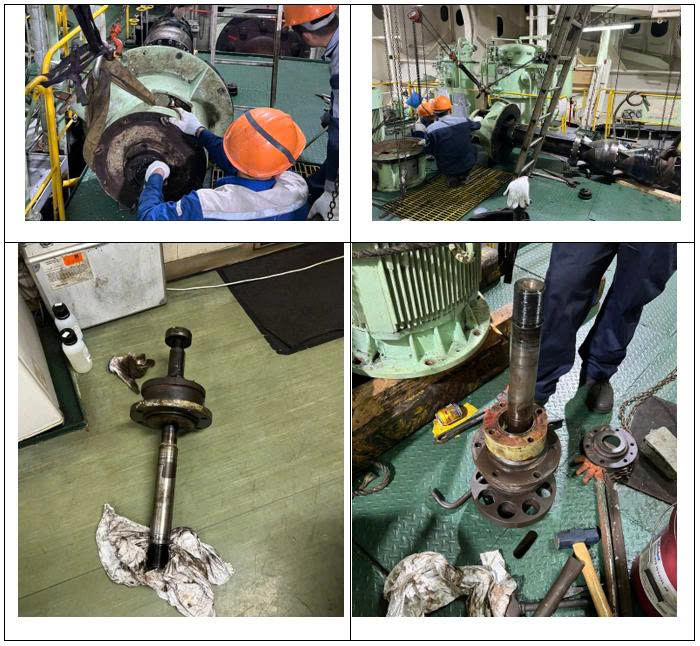

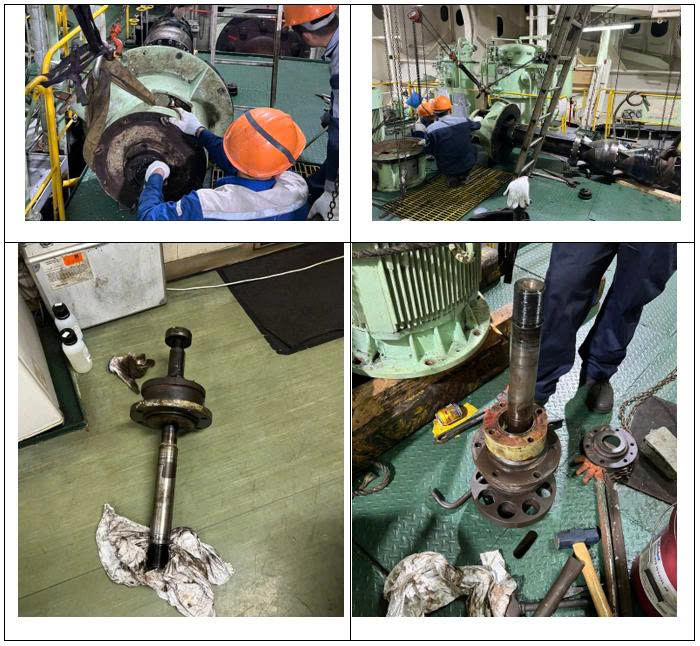

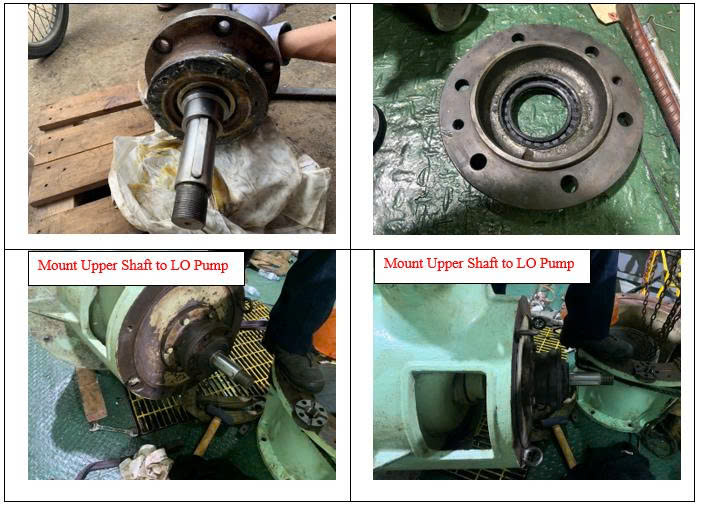

Disassemble for inspection and M.E L.O Pump Repairs

The Importance of the Main Engine Lubrication Oil Pump

The L.O pump plays a crucial role in ensuring consistent lubrication throughout the engine. It maintains the oil flow to key components, such as pistons, bearings, and the crankshaft. Consequently, the pump reduces friction, minimizes wear, and supports a stable operating temperature.

A malfunctioning pump can lead to overheating, component seizure, and severe engine failure. Therefore, regular M.E L.O Pump Repairs are essential to prevent breakdowns and ensure vessel safety.

Why Periodic Maintenance and M.E L.O Pump Repairs Are Necessary

Even durable pumps experience wear over time. Early indicators like abnormal noise, pressure drops, or metal particles in filters signal potential failures.

For instance, in our recent repair project, such symptoms prompted a full replacement of the Upper Shaft and Bearing Housing. Timely action prevented further engine damage and minimized operational downtime.

Moreover, consistent maintenance practices extend equipment life and reduce unexpected repair costs.

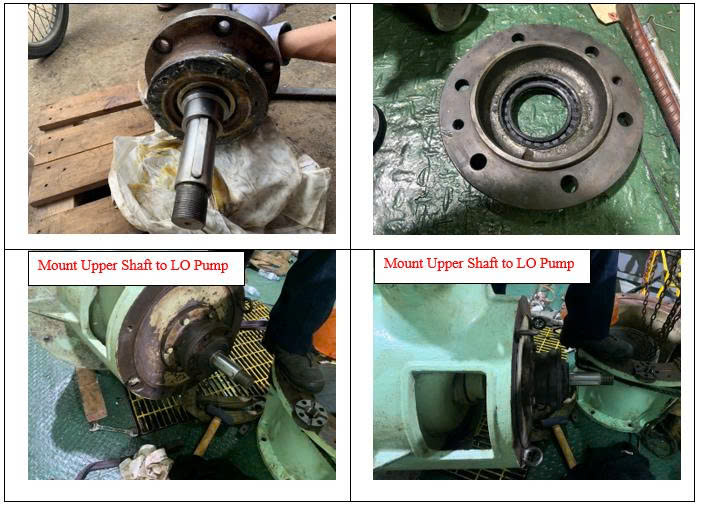

Replacement of bearing housing and upper shaft in progress

Step-by-Step Repair Procedure

To deliver consistent quality, VietNam ShipRepair implements a standardized repair process:

1. Initial Diagnosis and Inspection

We begin by disconnecting the pump from the engine. Our team measures shaft tolerances and bearing clearances while analyzing oil samples.

2. Disassembly

Next, we disassemble the pump and remove the worn upper shaft and damaged bearing housing.

3. Workshop Preparation

In our fabrication workshop, new parts are prepared and machined to exact alignment specifications. In addition, we replace seals and gaskets, then clean and balance the components.

4. Installation Onboard

After the components pass inspection, we reinstall the pump onboard. Our engineers perform rotation and pressure tests to verify performance.

5. Final Testing and Reporting

We conduct engine trials under load to confirm functionality. Finally, we deliver a detailed report, including photos and test logs, to the shipowner.

Technical Requirements and Standards

Repairs by VietNam ShipRepair consistently meet rigorous international standards:

- Shaft runout: < 0.03 mm

- Oil pressure (idle/load): OEM-specific

- Alignment tolerance: Within 0.02 mm

- Vibration: Within ISO/ABS limits

- Lubrication oil: OEM-grade, filtered and verified

All procedures comply with IMO and IACS standards, ensuring classification approval and long-term reliability.

M.E L.O Pump Repairs: Completed pump tested with pressure gauge before final approval

Our Service Coverage in Vietnam

Although this repair took place at Vung Tau Port, we operate nationwide with the same high standards at:

- Da Nang Port

- Nghi Son Terminal

- Ho Chi Minh Port

- Thi Vai – Cai Mep Complex

- Cam Pha and Cua Lo Anchorages

Regardless of your ship’s location, our mobile service teams are ready to provide quick and efficient assistance.

Why Choose VietNam ShipRepair?

Selecting a reliable marine repair service provider reduces downtime and enhances vessel performance. VietNam ShipRepair offers:

- 24/7 nationwide service

- Certified engineers and technicians

- OEM-quality parts and tools

- Comprehensive documentation and transparency

- Full compliance with international regulations

In short, we help shipowners save time, reduce costs, and maintain vessel integrity.

Get in Touch

Do not wait for failure to strike. For both emergency support and scheduled services, contact VietNam ShipRepair today.