Ultrasonic Testing for Hatch Covers at Da Nang Port – Expert Marine Services by Vietnam Shiprepair

Are you seeking reliable Marine Services to ensure the watertight integrity of hatch covers on your Panamax bulk carrier at Da Nang Port? Vietnam Shiprepair Co. specializes in Ultrasonic Testing and comprehensive Ship Repair solutions, delivering top-quality maintenance without disrupting tight schedules. In September 2025, we successfully performed Ultrasonic Testing on four hatch covers of a Panamax vessel at Da Nang Port, ensuring compliance with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards. Our Marine Services extend to key Vietnamese ports like Nghi Son, Vung Tau, and Ho Chi Minh City. Trust our Vietnam Workshop for professional, safe, and efficient hatch cover maintenance—learn more at IACS Standards.

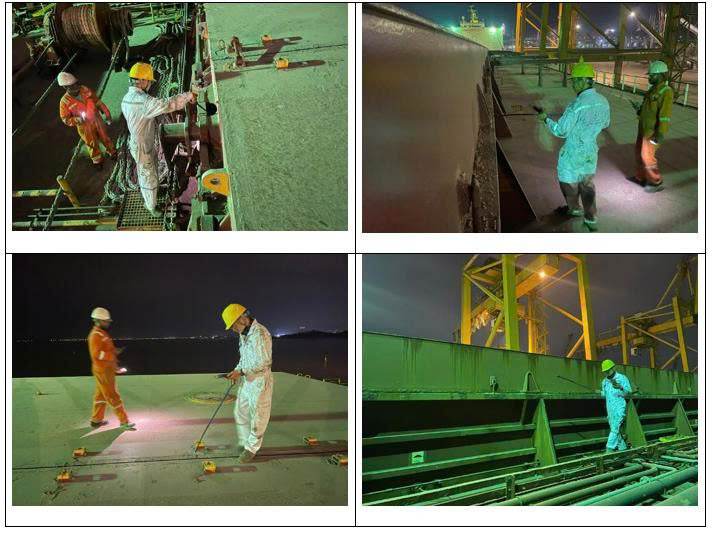

Panamax ship during hatch cover ultrasonic testing at Da Nang.

Panamax ship during hatch cover ultrasonic testing at Da Nang.

Importance of Ultrasonic Testing for Hatch Covers on Panamax Ships

Hatch covers on Panamax bulk carriers (60,000-80,000 DWT) are critical for protecting dry bulk cargo, such as coal or grain at Da Nang Port, from water ingress and environmental damage. Ultrasonic Testing is a non-destructive method to detect leaks, cracks, or wear in hatch covers, ensuring watertight integrity and preventing costly cargo damage. At Da Nang, where humid coastal conditions and frequent rains accelerate corrosion, regular Ultrasonic Testing by Vietnam Shiprepair’s Marine Services ensures vessel safety, compliance with IACS/IMO standards, and client satisfaction, even under demanding operational schedules.

Why Choose Ultrasonic Testing?

Ultrasonic Testing is the preferred method for hatch cover inspections due to its precision and efficiency. Compared to hose or chalk tests, it:

-

Detects micro-leaks invisible to the naked eye.

-

Identifies structural weaknesses in hatch cover joints or seals.

-

Minimizes downtime, critical for vessels at Da Nang Port operating on tight routes.

-

Ensures compliance with IACS UR S14 and IMO SOLAS Chapter II-1, mandatory for seaworthiness certification.

Our Vietnam Workshop teams use advanced ultrasonic equipment to deliver accurate results, safeguarding your cargo and vessel.

Steps to Perform Ultrasonic Testing for Hatch Covers

Vietnam Shiprepair recently conducted Ultrasonic Testing on four hatch covers of a Panamax bulk carrier at Da Nang Port, adhering to strict IACS/IMO protocols. Here’s the detailed process:

-

Preparation and Safety Setup

Our Vietnam Workshop team coordinates with the ship’s crew to ensure safe conditions at Da Nang Port’s Tien Sa or Han River terminals. We erect sturdy scaffolding for access to elevated hatch covers (5-10m above deck) and equip workers with full PPE (harnesses, helmets, gloves), complying with IMO safety regulations. Weather checks prevent disruptions from Da Nang’s coastal rains or winds.

-

Equipment Calibration

Certified technicians calibrate ultrasonic testing devices (e.g., Class-approved models like SDT Sherlog) to detect leaks with high accuracy. The device emits ultrasonic waves and measures reflections to identify defects.

-

Ultrasonic Testing Procedure

-

Close all hatch covers securely.

-

Place an ultrasonic transmitter inside the cargo hold to emit sound waves.

-

Use a receiver on the deck to scan hatch cover seals, joints, and cleats for leaks, indicated by sound wave loss.

-

Mark areas with detected leaks or weaknesses for further inspection.

-

Inspection and Maintenance

-

For identified leaks, inspect rubber seals (packing rubber) for wear or damage, replacing them if necessary.

-

Check cleats and hydraulic systems for corrosion or misalignment, common issues in Da Nang’s humid environment.

-

Apply anti-corrosion coatings (e.g., epoxy) and lubricate moving parts to restore functionality.

-

Reporting and Certification

Generate a detailed hatch cover survey report, reviewed by classification societies like NK or DNV, to confirm IACS/IMO compliance. At Da Nang, the Da Nang Port Authority may verify results for operational clearance. The process typically takes 2-3 days for four hatch covers.

Team conducting ultrasonic testing on Panamax hatch covers.

Team conducting ultrasonic testing on Panamax hatch covers.

Safety and Professionalism in Marine Services

At Da Nang Port, where vessels face tight schedules and challenging weather, Vietnam Shiprepair’s Marine Services prioritize safety and efficiency. Our Vietnam Workshop team adheres to IMO safety guidelines, using full-body harnesses, weather monitoring, and dual supervision to mitigate risks of working at heights. Clear communication and regular updates ensure client confidence, preventing delays that could disrupt cargo routes.

Vietnam Shiprepair’s Nationwide Marine Services Network

Our Marine Services cover all major Vietnamese ports and anchorages:

-

Da Nang Port: Ideal for Ultrasonic Testing and repairs, as demonstrated in our recent project.

-

Nghi Son Anchorage: A hub for efficient Ship Repair solutions.

-

Nationwide Reach: Serving Vung Tau, Ho Chi Minh City, and beyond.

-

Mobile Operations: Our Vietnam Workshop brings advanced ultrasonic equipment to your vessel.

-

Rapid Response: Quick deployment minimizes downtime.

Explore our offerings at Vietnam Shiprepair Services.

Benefits of Choosing Vietnam Shiprepair for Ultrasonic Testing

Partnering with Vietnam Shiprepair for Marine Services offers:

-

IACS/IMO-compliant Ultrasonic Testing, ensuring watertight hatch covers and cargo safety.

-

Cost-effective maintenance, preventing expensive repairs from water damage.

-

Experienced Vietnam Workshop technicians, with over 20 years of expertise.

-

Fast turnaround, keeping your Panamax vessel on schedule at Da Nang Port.

-

Detailed reports, enhancing vessel reliability and client trust.

Vietnam Shiprepair’s Commitment to Excellence

Our Marine Services combine skilled personnel, advanced Ultrasonic Testing technology, and strict adherence to IACS/IMO standards. Supervised by classification societies, our Vietnam Workshop delivers flawless results, satisfying even the most demanding clients. Choose Vietnam Shiprepair for reliable hatch cover maintenance at Da Nang Port!

Contact Vietnam Shiprepair

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.