- by Vietnam Ship Repair

- 0

Cell Guide Replacement at Cai Mep Port

Cell Guide Replacement at Cai Mep Port – Expert Marine Services by Vietnam Shiprepair

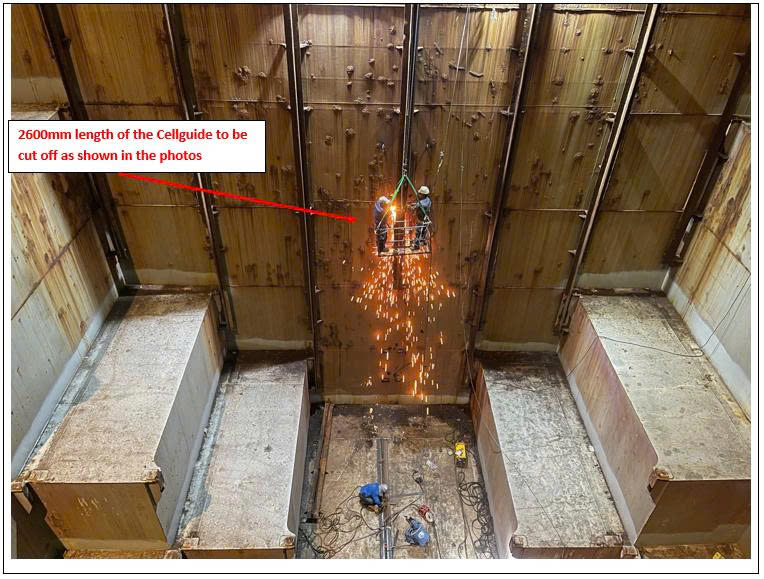

Are you seeking reliable Marine Services for Time efficiency, The best Standard on your Feeder-type container ship at Cai Mep Port, but concerned about downtime and tight schedules? Vietnam Shiprepair Co. excels in Ship Repair and Marine Services, delivering high-quality solutions with an emphasis on time efficiency. In September 2025, we successfully completed a cell guide replacement of a 9-meter section in one cargo hold of a Feeder container ship at Cai Mep Port, finishing in just 9 hours while adhering to International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards. Our Marine Services span major Vietnamese ports like Nghi Son, Vung Tau, and Ho Chi Minh City. Trust our Vietnam Workshop for rapid, safe, and professional repairs—learn more at IACS Standards.

Feeder container ship undergoing cell guide replacement in hold at Cai Mep Port.

Feeder container ship undergoing cell guide replacement in hold at Cai Mep Port.

Importance of Cell Guide Replacement in Feeder Container Ships

Cell guides are critical vertical steel rails in the cargo holds of Feeder-type container ships (500-3,000 TEU), ensuring containers are securely stacked and aligned to prevent shifting during transit. At Cai Mep Port, a key deep-water hub in Vietnam, these structures face corrosion and wear due to high humidity and saline conditions. A cell guide replacement is vital to maintain vessel stability, protect cargo (e.g., electronics or textiles), and ensure seamless loading operations. Time efficiency in cell guide replacement is paramount for container ships, as even a few hours of delay can disrupt tight schedules and lead to significant financial losses. Vietnam Shiprepair’s Marine Services deliver rapid repairs, ensuring IACS/IMO compliance and minimal downtime at this bustling port.

Why Choose Professional Cell Guide Replacement?

Professional cell guide replacement prevents structural failures that could damage containers or compromise safety. Replacing a 9-meter section requires precision welding, alignment, and testing to meet IACS UR S11 standards. Our Vietnam Workshop leverages advanced techniques to complete repairs in just 9 hours, critical for Feeder ships on short-haul routes at Cai Mep Port. This rapid turnaround ensures compliance with IMO SOLAS Chapter II-1, safeguarding cargo and vessel seaworthiness while keeping schedules intact.

Steps to Perform Cell Guide Replacement in Container Ship Hold

Vietnam Shiprepair recently executed a cell guide replacement of a 9-meter section in the cargo hold of a Feeder container ship at Cai Mep Port, following strict IACS/IMO protocols. Here’s the streamlined process:

-

Preparation and Assessment

Our Vietnam Workshop team assesses the damaged cell guide using visual checks and Ultrasonic Testing to confirm corrosion or deformation. We coordinate with the crew at Cai Mep Port’s Thi Vai or CMIT terminals, preparing welding equipment, cranes, and scaffolding for swift and safe hold access. -

Safe Dismantling

Erect sturdy scaffolding to access the 9-meter height in the hold (6-12m total). Using chain blocks and cutting torches, carefully remove the faulty cell guide section, ensuring no damage to adjacent structures. -

Fabrication and Installation

Fabricate a new 9-meter cell guide from high-strength steel in our Vietnam Workshop, coated with anti-corrosion epoxy to withstand Cai Mep’s saline environment. Weld the new guide into place with precise alignment for seamless container stacking. -

Welding and Reinforcement

Perform certified welding on joints, followed by Ultrasonic Testing to verify weld integrity and alignment, ensuring durability under heavy loads. -

Final Testing and Certification

Conduct load tests and inspections to confirm stability. Generate a detailed report for classification societies like NK or DNV, securing IACS/IMO compliance. The 9-hour process allowed the vessel to resume operations without delay, critical for maintaining tight schedules at Cai Mep Port.

Vietnam Workshop team performing cell guide replacement in container ship hold at Cai Mep Port.

Vietnam Workshop team performing cell guide replacement in container ship hold at Cai Mep Port.

Safety and Time Efficiency in Marine Services

Replacing cell guides in confined holds at Cai Mep Port requires stringent safety and speed. Vietnam Shiprepair’s Marine Services adhere to IMO safety guidelines, using full PPE (harnesses, respirators, helmets), ventilation systems, and dual supervision. We monitor Cai Mep’s coastal weather to avoid disruptions, ensuring rapid execution to prevent costly delays. Our 9-hour cell guide replacement exemplifies our commitment to time efficiency, vital for Feeder ships on high-frequency routes.

Vietnam Shiprepair’s Nationwide Marine Services Network

Our Marine Services cover Vietnam’s key maritime hubs:

-

Cai Mep Port: A deep-water hub ideal for Feeder ship repairs, as shown in our recent cell guide project.

-

Nghi Son Anchorage: A center for efficient Ship Repair solutions.

-

Nationwide Reach: Serving Vung Tau, Ho Chi Minh City, and all ports/anchorages.

-

Mobile Operations: Our Vietnam Workshop brings advanced tools to your vessel.

-

Rapid Response: Swift deployment minimizes downtime.

Explore our offerings at Vietnam Shiprepair Services.

Benefits of Choosing Vietnam Shiprepair for Cell Guide Replacement

Choosing Vietnam Shiprepair for Marine Services offers:

-

IACS/IMO-compliant cell guide replacement, ensuring hold integrity and cargo safety.

-

Rapid 9-hour turnaround, critical for Feeder ship schedules at Cai Mep Port.

-

Cost-effective repairs, preventing extensive damage from faulty cell guides.

-

Skilled Vietnam Workshop technicians with over 20 years of expertise.

-

Detailed reports, enhancing vessel reliability and client trust.

Image placeholder 3: Feeder container ship after cell guide replacement, operating smoothly at Cai Mep Port. Alt text: Feeder ship post-cell guide replacement in stable operation.

Vietnam Shiprepair’s Commitment to Excellence

Our process—from assessment to certification—integrates expert personnel, advanced tools like Ultrasonic Testing, and strict IACS/IMO compliance. Supervised by classification societies, our Vietnam Workshop delivers flawless cell guide replacement, minimizing downtime and satisfying demanding clients. Trust Vietnam Shiprepair for superior Marine Services at Cai Mep Port!

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Ultrasonic Testing for Hatch Covers at Da Nang Port

Ultrasonic Testing for Hatch Covers at Da Nang Port – Expert Marine Services by Vietnam Shiprepair

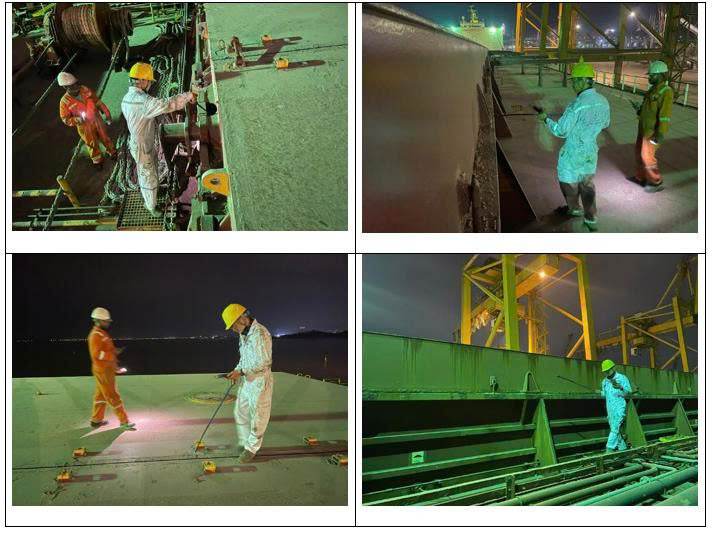

Are you seeking reliable Marine Services to ensure the watertight integrity of hatch covers on your Panamax bulk carrier at Da Nang Port? Vietnam Shiprepair Co. specializes in Ultrasonic Testing and comprehensive Ship Repair solutions, delivering top-quality maintenance without disrupting tight schedules. In September 2025, we successfully performed Ultrasonic Testing on four hatch covers of a Panamax vessel at Da Nang Port, ensuring compliance with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards. Our Marine Services extend to key Vietnamese ports like Nghi Son, Vung Tau, and Ho Chi Minh City. Trust our Vietnam Workshop for professional, safe, and efficient hatch cover maintenance—learn more at IACS Standards.

Panamax ship during hatch cover ultrasonic testing at Da Nang.

Panamax ship during hatch cover ultrasonic testing at Da Nang.

Importance of Ultrasonic Testing for Hatch Covers on Panamax Ships

Hatch covers on Panamax bulk carriers (60,000-80,000 DWT) are critical for protecting dry bulk cargo, such as coal or grain at Da Nang Port, from water ingress and environmental damage. Ultrasonic Testing is a non-destructive method to detect leaks, cracks, or wear in hatch covers, ensuring watertight integrity and preventing costly cargo damage. At Da Nang, where humid coastal conditions and frequent rains accelerate corrosion, regular Ultrasonic Testing by Vietnam Shiprepair’s Marine Services ensures vessel safety, compliance with IACS/IMO standards, and client satisfaction, even under demanding operational schedules.

Why Choose Ultrasonic Testing?

Ultrasonic Testing is the preferred method for hatch cover inspections due to its precision and efficiency. Compared to hose or chalk tests, it:

-

Detects micro-leaks invisible to the naked eye.

-

Identifies structural weaknesses in hatch cover joints or seals.

-

Minimizes downtime, critical for vessels at Da Nang Port operating on tight routes.

-

Ensures compliance with IACS UR S14 and IMO SOLAS Chapter II-1, mandatory for seaworthiness certification.

Our Vietnam Workshop teams use advanced ultrasonic equipment to deliver accurate results, safeguarding your cargo and vessel.

Steps to Perform Ultrasonic Testing for Hatch Covers

Vietnam Shiprepair recently conducted Ultrasonic Testing on four hatch covers of a Panamax bulk carrier at Da Nang Port, adhering to strict IACS/IMO protocols. Here’s the detailed process:

-

Preparation and Safety Setup

Our Vietnam Workshop team coordinates with the ship’s crew to ensure safe conditions at Da Nang Port’s Tien Sa or Han River terminals. We erect sturdy scaffolding for access to elevated hatch covers (5-10m above deck) and equip workers with full PPE (harnesses, helmets, gloves), complying with IMO safety regulations. Weather checks prevent disruptions from Da Nang’s coastal rains or winds. -

Equipment Calibration

Certified technicians calibrate ultrasonic testing devices (e.g., Class-approved models like SDT Sherlog) to detect leaks with high accuracy. The device emits ultrasonic waves and measures reflections to identify defects. -

Ultrasonic Testing Procedure

-

Close all hatch covers securely.

-

Place an ultrasonic transmitter inside the cargo hold to emit sound waves.

-

Use a receiver on the deck to scan hatch cover seals, joints, and cleats for leaks, indicated by sound wave loss.

-

Mark areas with detected leaks or weaknesses for further inspection.

-

-

Inspection and Maintenance

-

For identified leaks, inspect rubber seals (packing rubber) for wear or damage, replacing them if necessary.

-

Check cleats and hydraulic systems for corrosion or misalignment, common issues in Da Nang’s humid environment.

-

Apply anti-corrosion coatings (e.g., epoxy) and lubricate moving parts to restore functionality.

-

-

Reporting and Certification

Generate a detailed hatch cover survey report, reviewed by classification societies like NK or DNV, to confirm IACS/IMO compliance. At Da Nang, the Da Nang Port Authority may verify results for operational clearance. The process typically takes 2-3 days for four hatch covers.

Team conducting ultrasonic testing on Panamax hatch covers.

Team conducting ultrasonic testing on Panamax hatch covers.

Safety and Professionalism in Marine Services

At Da Nang Port, where vessels face tight schedules and challenging weather, Vietnam Shiprepair’s Marine Services prioritize safety and efficiency. Our Vietnam Workshop team adheres to IMO safety guidelines, using full-body harnesses, weather monitoring, and dual supervision to mitigate risks of working at heights. Clear communication and regular updates ensure client confidence, preventing delays that could disrupt cargo routes.

Vietnam Shiprepair’s Nationwide Marine Services Network

Our Marine Services cover all major Vietnamese ports and anchorages:

-

Da Nang Port: Ideal for Ultrasonic Testing and repairs, as demonstrated in our recent project.

-

Nghi Son Anchorage: A hub for efficient Ship Repair solutions.

-

Nationwide Reach: Serving Vung Tau, Ho Chi Minh City, and beyond.

-

Mobile Operations: Our Vietnam Workshop brings advanced ultrasonic equipment to your vessel.

-

Rapid Response: Quick deployment minimizes downtime.

Explore our offerings at Vietnam Shiprepair Services.

Benefits of Choosing Vietnam Shiprepair for Ultrasonic Testing

Partnering with Vietnam Shiprepair for Marine Services offers:

-

IACS/IMO-compliant Ultrasonic Testing, ensuring watertight hatch covers and cargo safety.

-

Cost-effective maintenance, preventing expensive repairs from water damage.

-

Experienced Vietnam Workshop technicians, with over 20 years of expertise.

-

Fast turnaround, keeping your Panamax vessel on schedule at Da Nang Port.

-

Detailed reports, enhancing vessel reliability and client trust.

Vietnam Shiprepair’s Commitment to Excellence

Our Marine Services combine skilled personnel, advanced Ultrasonic Testing technology, and strict adherence to IACS/IMO standards. Supervised by classification societies, our Vietnam Workshop delivers flawless results, satisfying even the most demanding clients. Choose Vietnam Shiprepair for reliable hatch cover maintenance at Da Nang Port!

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Mushroom Ventilator Maintenance at Cam Pha Anchorage

Mushroom Ventilator Maintenance at Cam Pha Anchorage – Professional Solutions by Vietnam Shiprepair

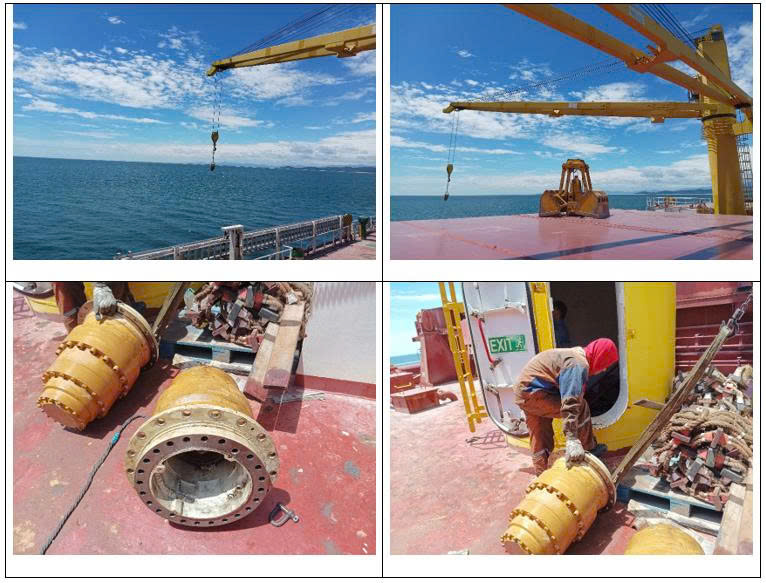

Are you seeking reliable mushroom ventilator maintenance for a Panamax ship at Cam Pha Anchorage, but concerned about safety risks, handling heavy equipment, and adhering to tight schedules? Vietnam Shiprepair Co. provides top-tier Marine Services, including Ship Repair and specialized maritime solutions. In September 2025, we successfully completed maintenance on four large mushroom ventilators (ventilation fans) for a Panamax vessel at Cam Pha Anchorage, meeting rigorous safety standards without disrupting operations. Our Marine Services extend to key locations like Nghi Son, Vung Tau, and Ho Chi Minh City. All work complies with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Choose Vietnam Shiprepair for expert Vietnam Workshop solutions!

Panamax ship with mushroom ventilators requiring maintenance at Cam Pha Anchorage before repair.

Panamax ship with mushroom ventilators requiring maintenance at Cam Pha Anchorage before repair.

Importance of Mushroom Ventilator Maintenance for Panamax Ships

Mushroom ventilators are critical for Panamax ships at Cam Pha Anchorage, ensuring proper ventilation in engine rooms to remove exhaust gases, heat, and moisture while preventing corrosion in harsh marine environments. For operators facing demanding schedules, high-quality maintenance is vital to avoid downtime and safety hazards. Vietnam Shiprepair’s Marine Services guarantee IACS/IMO compliance, superior workmanship, and client satisfaction, even in challenging conditions like Cam Pha’s humid and windy anchorage.

Steps to Perform Mushroom Ventilator Maintenance Services

Vietnam Shiprepair recently handled maintenance for four oversized mushroom ventilators on a Panamax ship at Cam Pha Anchorage, adhering to strict protocols. The key steps include:

-

Arranging Qualified Personnel

A team of 6-8 skilled technicians from our Vietnam Workshop, experienced in heavy lifting and marine equipment, supervised by a certified leader. -

Safe Access and Preparation

Erect sturdy scaffolding to reach the elevated positions (5-10m above deck), and secure chain blocks for safe dismantling, ensuring stability against sea winds. -

Dismantling and Lowering

Carefully remove the heavy ventilators (each weighing hundreds of kilograms) using chain blocks, lowering them to the deck for inspection. -

Inspection, Cleaning, and Refurbishment

-

Remove rust with high-pressure blasting or wire brushes, addressing the corrosive effects of Cam Pha’s saline environment.

-

Apply anti-corrosion coatings (e.g., epoxy) to protect against seawater and humidity.

-

Lubricate mechanisms and replace damaged components like grilles.

-

-

Reinstallation and Testing

Hoist units back into place, test airflow and watertightness, completing the job within 3-5 days.

This process demands precision and safety, fully compliant with IACS and IMO guidelines to prevent accidents and ensure longevity.

Importance of Professional Attitude and Safe, Fast Turnaround

At Cam Pha Anchorage, where vessels operate on tight routes, a professional attitude and rapid execution are vital. Vietnam Shiprepair’s Marine Services team maintains clear communication, provides progress updates, and prioritizes safety with full PPE (harnesses, helmets, gloves) and weather monitoring. We minimize delays that could lead to costly disruptions, ensuring your Panamax ship resumes operations swiftly while upholding IACS/IMO standards.

Vietnam Shiprepair’s Compliance with Mushroom Ventilator Maintenance Services

As a trusted provider, Vietnam Shiprepair follows rigorous procedures in our Vietnam Workshop facilities. We use IACS-certified tools and materials, with oversight from classification societies like NK, guaranteeing IMO compliance for safety and environmental protection. This ensures even the most demanding clients receive flawless results at Cam Pha Anchorage.

Vietnam Shiprepair’s Nationwide Marine Services Network

We deliver comprehensive Marine Services, including mushroom ventilator maintenance, across Vietnam:

-

Cam Pha Anchorage: Perfect for anchorage-based repairs, as shown in our recent project.

-

Nghi Son Anchorage: A major hub for efficient Vietnam Shiprepair solutions.

-

Nationwide Reach: Serving Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our Vietnam Workshop teams deploy with specialized equipment directly to your vessel.

-

Rapid Response: Quick mobilization reduces downtime and enhances efficiency.

Discover more at Vietnam Shiprepair Services.

Technical team performing mushroom ventilator maintenance on a Panamax ship at Cam Pha Anchorage.

Technical team performing mushroom ventilator maintenance on a Panamax ship at Cam Pha Anchorage.

Benefits of Choosing Vietnam Shiprepair for Marine Services

Opting for Vietnam Shiprepair’s Marine Services brings unmatched advantages:

-

Professional approach and IACS/IMO-compliant workmanship keep schedules intact at Cam Pha Anchorage.

-

Cost-effective maintenance prevents major overhauls.

-

Experienced Vietnam Workshop technicians boost vessel safety and operational reliability.

-

With over 20 years in the industry, we provide detailed reports and peace of mind, enhancing your fleet’s reputation and reducing long-term expenses.

Vietnam Shiprepair’s Commitment to Excellence

Our meticulous process—from skilled personnel arrangement and thorough preparation to high-quality refurbishment and timely completion—ensures top results. We strictly adhere to IACS and IMO standards with classification society supervision, satisfying even the toughest clients. Trust Vietnam Shiprepair for superior Marine Services!

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

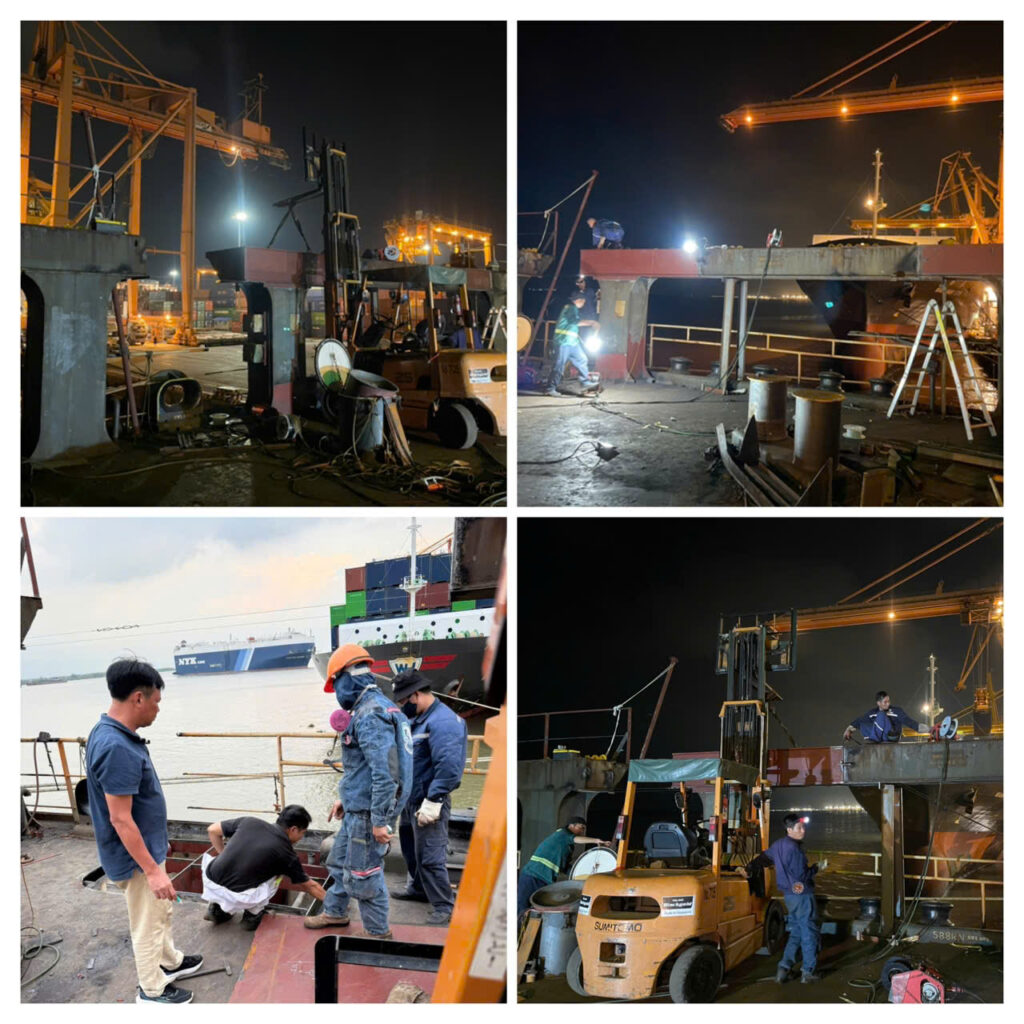

Deck Crane Repair at Quang Binh Anchorage

Deck Crane Repair at Quang Binh Anchorage – Expert Marine Services by Vietnam Shiprepair

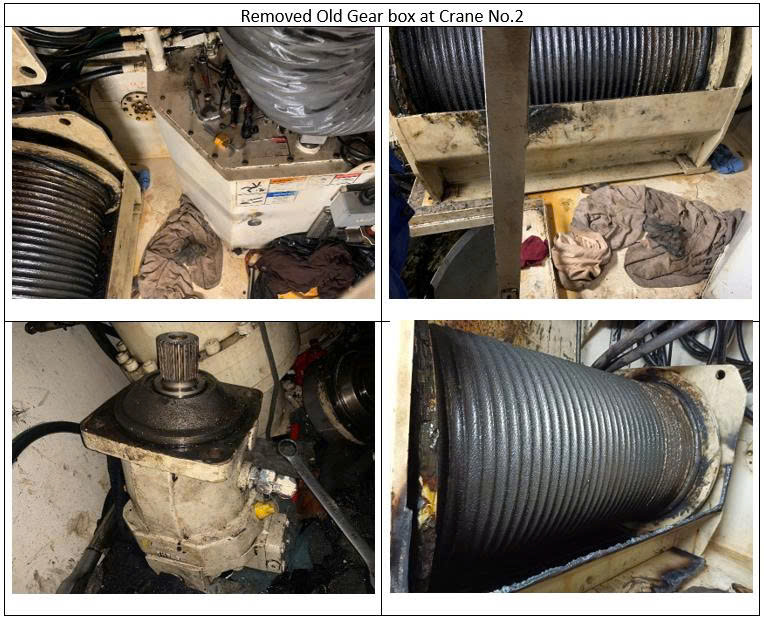

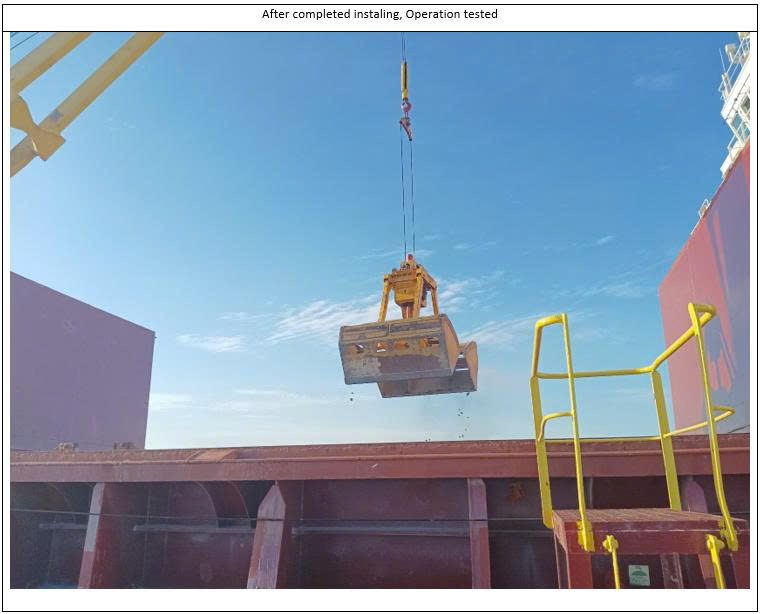

Is your vessel’s deck crane at Quang Binh Anchorage in need of urgent gearbox replacement? Vietnam Shiprepair Co. offers top-notch Deck Crane Repair and Marine Services, ensuring operational efficiency. On September , 2025, we successfully replaced gearboxes for cranes number 2 and 4 on a bulk carrier anchored at Quang Binh, meeting tight schedules with precision. Our services cover all anchorages and ports across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. All repairs adhere to International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust Vietnam Shiprepair for reliable solutions!

Damaged gearbox of deck crane number 2 at Quang Binh Anchorage before repair.

Damaged gearbox of deck crane number 2 at Quang Binh Anchorage before repair.

Importance of Deck Crane Gearbox Replacement

Deck cranes are essential for bulk carriers at Quang Binh Anchorage, enabling the loading and unloading of cargo like ore or wood chips. When gearboxes for cranes number 2 and 4 fail due to wear or overloading, it halts operations and compromises safety. Timely Deck Crane Repair by Vietnam Shiprepair restores functionality, ensuring IACS/IMO compliance and minimizing downtime for anchored vessels.

Steps for Deck Crane Gearbox Replacement

Vietnam Shiprepair recently replaced gearboxes for cranes number 2 and 4 at Quang Binh Anchorage due to operational wear. Here’s the process:

-

Initial Assessment: Inspect the faulty gearboxes using diagnostic tools to identify wear on gears and bearings.

-

Disassembly: Carefully remove the old gearboxes from the winch drums, ensuring no impact on the crane’s structural integrity, using specialized lifting equipment.

-

Installation of New Gearboxes: Fit high-quality replacement gearboxes with a transmission ratio of 50:1, calibrated for optimal performance with the winch system.

-

Testing and Calibration: Perform a load test (up to 35 tons SWL) and verify oil circulation, supervised by NK, to ensure smooth operation.

This process requires expertise to maintain crane efficiency without delays.

Importance of Minimizing Downtime with Marine Services

Replacing crane gearboxes quickly is critical at Quang Binh Anchorage to avoid schedule disruptions. Delays can result in significant financial losses and missed cargo deadlines. Vietnam Shiprepair’s Marine Services focus on rapid response, completing repairs efficiently with mobile support, ensuring IACS/IMO compliance and client satisfaction.

Vietnam Shiprepair’s Compliance with Deck Crane Repair

A trusted provider must adhere to strict standards. Vietnam Shiprepair employs advanced repair techniques and NK-certified technicians. The process is supervised by NK, guaranteeing compliance with IMO and IACS guidelines for reliable, safe deck cranes.

Vietnam Shiprepair’s Nationwide Marine Services Network

Offers Marine Services, including Deck Crane Repair, across Vietnam:

-

Quang Binh Anchorage: Ideal for efficient repairs, as demonstrated recently.

-

Nghi Son Anchorage: A key location for Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

Technical team installing new gearbox on deck crane number 4 at Quang Binh Anchorage.

Technical team installing new gearbox on deck crane number 4 at Quang Binh Anchorage.

Benefits of Choosing Vietnam Shiprepair for Deck Crane Repair

Choosing Vietnam Shiprepair for Deck Crane Repair ensures peace of mind. Our Marine Services save time, maintaining schedules at Quang Binh Anchorage. High-quality gearbox replacements reduce future breakdowns. Our NK-certified experts enhance vessel safety and reputation, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Repaired deck crane number 2 in stable operation at Quang Binh Anchorage.

Repaired deck crane number 2 in stable operation at Quang Binh Anchorage.

Vietnam Shiprepair’s Commitment to Excellence

Our repair process guarantees quality. We assess damage, disassemble safely, install new gearboxes, and test thoroughly. We uphold IACS and IMO standards with NK supervision throughout. Choose Vietnam Shiprepair for dependable Marine Services.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Marine Paint Touch-Up Services at Phu My Port

Marine Paint Touch-Up Services at Phu My Port – Professional Solutions by Vietnam Shiprepair

Do you need paint touch-up services for a container ship on a dedicated route at Phu My Port but are concerned about tight schedules and demanding client requirements? Vietnam Shiprepair Co. provides Marine Paint Services, Ship Repair, and professional maritime solutions. On August, 2025, we successfully completed a paint touch-up job for a container ship at Phu My Port, meeting the demands of a challenging client without delaying the schedule. Our services extend to ports like Nghi Son, Vung Tau, and Ho Chi Minh City. Our work complies with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Choose Vietnam Shiprepair!

Container ship requiring paint touch-up at Phu My Port before repair.

Container ship requiring paint touch-up at Phu My Port before repair.

Importance of Paint Touch-Up for Container Ships on Dedicated Routes

Paint touch-up is a critical maintenance step for container ships on dedicated routes at Phu My Port, protecting the hull from corrosion and rust in harsh marine conditions. For demanding clients, the quality of the paintwork and fast turnaround are essential to avoid schedule disruptions. Vietnam Shiprepair’s Marine Paint Services ensures safety, IACS/IMO compliance, and satisfaction even for the most exacting customers.

Steps to Perform Marine Paint Touch-Up Services

Vietnam Shiprepair recently conducted a paint touch-up for a container ship at Phu My Port, meeting strict client demands. Here are the key steps:

-

Arranging Qualified Personnel: A team of 5-7 trained workers with experience in epoxy painting and spray equipment, supervised by a team leader.

-

Rapid Preparation: Clean the surface with blasting equipment before the ship docks to ensure adhesion.

-

High-Quality Painting: Apply fast-drying paint (2-4 hours) with a thickness of 100-150 microns, checked with a gauge, adhering to NK standards.

-

Timely Completion: Use drying lamps to accelerate the process, finishing within 4-6 hours.

This process ensures quality but requires tight coordination to avoid delays.

Importance of Professional Attitude and Fast Turnaround

For demanding clients, a professional attitude and rapid progress are key at Phu My Port. Vietnam Shiprepair’s team communicates clearly, provides regular updates, and completes the job on time, ensuring the container ship stays on its dedicated route schedule. Delays can cause significant losses, and we are committed to minimizing this risk.

Vietnam Shiprepair’s Compliance with Paint Touch-Up Services

A reputable provider must follow strict procedures. Vietnam Shiprepair uses high-quality paint and IACS-certified personnel, with supervision from NK, ensuring compliance with IMO and IACS standards to satisfy even the most challenging clients.

Vietnam Shiprepair’s Nationwide Marine Services Network

Provides Marine Service, including Marine Paint Services, across Vietnam:

-

Phu My Port: Ideal for quick repairs, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for efficient Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

After Technical team performing paint touch-up on a container ship at Phu My Port.

After Technical team performing paint touch-up on a container ship at Phu My Port.

Benefits of Choosing Vietnam Shiprepair for Marine Paint Services

Choosing Vietnam Shiprepair for Marine Paint Services offers peace of mind. A professional attitude, high-quality paintwork meeting standards, and fast progress maintain schedules at Phu My Port. Cost-effective solutions reduce major maintenance expenses. Our NK-certified technicians enhance vessel safety and reputation, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Vietnam Shiprepair’s Commitment to Excellence

Our process ensures quality. We arrange skilled personnel, prepare thoroughly, apply high-quality paint, and complete on schedule. We adhere to IACS and IMO standards with NK supervision, satisfying even the most demanding clients. Choose Vietnam Shiprepair!

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Stiff Boom Crane Repair at Phu My Port

Stiff Boom Crane Repair at Phu My Port – Professional Services by Vietnam Shiprepair

Do you have a stiff boom crane on your bulk carrier damaged at Phu My Port? Vietnam Shiprepair Co. offers expert Crane Repair, Marine Service, and professional solutions, ensuring safe operations. On September, 2025, we successfully repaired a stiff boom crane deformed due to overloading at Phu My Port without affecting the working schedule. Our services extend to all ports and anchorages across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. Our repairs comply with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust Vietnam Shiprepair!

Damaged stiff boom crane at Phu My Port before repair.

Importance of Stiff Boom Cranes on Bulk Carriers

Stiff boom cranes are vital components on bulk carriers, facilitating the loading and unloading of cargo like ore or wood chips at Phu My Port. When a crane arm deforms due to overloading, it reduces efficiency, poses safety risks, and may violate IACS/IMO standards. Vietnam Shiprepair’s Crane Repair restores functionality, ensuring safety and compliance.

Basic Steps for Stiff Boom Crane Repair

Vietnam Shiprepair recently repaired a stiff boom crane at Phu My Port due to deformation from overloading. Here are the key steps:

-

Initial Inspection: Assess the deformation extent using measurements and structural checks to identify the replacement area.

-

Disassembly of Damaged Section: Cut away the deformed steel section with precision thermal cutting, preserving the overall crane structure.

-

Replacement with AH36 Steel: Use AH36 steel—the original material—to weld and reinforce the replacement section, ensuring structural compatibility, with the process supervised by NK.

-

Testing and Finishing: Conduct a load test (30-35 tons SWL) and apply an anti-corrosion coating for protection.

This process maintains integrity but requires timely execution to avoid disruptions.

Importance of Minimizing Downtime During Repair

Repairing a stiff boom crane quickly without impacting the working schedule is crucial at Phu My Port. Delays can lead to financial losses and missed shipping plans. Vietnam Shiprepair prioritizes efficient Crane Repair, supported by workshop resources, reducing weather-related risks and ensuring IACS/IMO compliance.

Vietnam Shiprepair’s Compliance with Crane Repair

A reputable repair provider must follow strict procedures. Vietnam Shiprepair employs advanced welding techniques with AH36 steel and NK-certified welders. The process is supervised by NK, ensuring compliance with IMO and IACS standards for durable, safe crane repairs.

Vietnam Shiprepair’s Nationwide Marine Services Network

Provides Marine Service, including Crane Repair, across Vietnam:

-

Phu My Port: Ideal for efficient repairs, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for quick Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

Technical team welding and reinforcing stiff boom crane at Phu My Port.

Benefits of Choosing Vietnam Shiprepair for Crane Repair

Choosing Vietnam Shiprepair for Crane Repair offers peace of mind. Our Marine Service saves time, maintaining schedules at Phu My Port. Using AH36 steel reduces costs compared to full replacements. Our NK-certified technicians enhance vessel safety and reputation, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Repaired stiff boom crane in stable operation at Vung Tau.

Vietnam Shiprepair’s Commitment to Excellence

Our repair process ensures quality. We inspect damage, safely disassemble, replace with AH36 steel, and test thoroughly. We maintain IACS and IMO compliance, supervised by NK throughout. Choose Vietnam Shiprepair for reliable Crane Repair.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Hatch Cover Repair at Da Nang Port

Hatch Cover Repair at Da Nang Port – Professional Services by Vietnam Shiprepair

Do you have a damaged hatch cover on your container ship at Da Nang Port? Vietnam Shiprepair Co. offers expert Hatch Cover Repair, Marine Service, and comprehensive solutions, ensuring vessel safety. On September 09, 2025, at 03:52 PM +07, we successfully repaired a lift-away (pontoon) hatch cover at Da Nang Port without interrupting loading schedules. Our services extend to all ports and anchorages across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. Our repairs comply with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust Vietnam Shiprepair for reliable solutions!

Damaged hatch cover due to overloading at Da Nang Port before repair.

Damaged hatch cover due to overloading at Da Nang Port before repair.

Importance of Hatch Covers for Container Ships

Hatch covers are critical for container ships, especially at Da Nang Port, protecting cargo holds from seawater and supporting container stacks on deck. A deformed hatch cover, such as one damaged by overloading at the hatch contact area, can lead to leaks, safety risks, or non-compliance with IACS and IMO standards. Vietnam Shiprepair’s Hatch Cover Repair restores integrity, ensuring compliance and operational efficiency.

Basic Steps for Hatch Cover Repair

Vietnam Shiprepair recently repaired a lift-away (pontoon) hatch cover at Da Nang Port due to deformation from overloading. Here are the key steps:

-

Initial Inspection: Assess the extent of deformation at the hatch contact area using visual checks and measurements.

-

Disassembly and Preparation: Remove the hatch cover, cut away the deformed steel, and prepare the surface for welding.

-

Welding and Reinforcement: Skilled welders use AH36 steel for reinforcement, following IACS standards, with the process supervised by DNV.

-

Testing and Finishing: Conduct a chalk test for watertightness, apply anti-corrosion coating, and reinstall the hatch cover.

This process ensured safety, but timely execution is essential to avoid disruptions.

Importance of Minimizing Downtime During Repair

Repairing a hatch cover quickly without affecting loading schedules is vital at Da Nang Port. Delays can result in financial losses and missed deadlines. Vietnam Shiprepair prioritizes rapid Hatch Cover Repair, completing tasks efficiently with workshop support. Quick service also reduces weather-related risks, ensuring IACS and IMO compliance.

Vietnam Shiprepair’s Compliance with Hatch Cover Repair

A reputable repair provider must adhere to strict standards. Vietnam Shiprepair employs advanced welding techniques with AH36 steel and DNV-certified welders. The repair process is supervised by DNV, guaranteeing adherence to IMO and IACS guidelines for durable, safe hatch covers.

Vietnam Shiprepair’s Nationwide Marine Services Network

Provides Marine Service, including Hatch Cover Repair, across Vietnam:

-

Da Nang Port: Ideal for efficient repairs, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for quick Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

Technical team welding and reinforcing hatch cover at Da Nang Port.

Technical team welding and reinforcing hatch cover at Da Nang Port.

Benefits of Choosing Vietnam Shiprepair for Hatch Cover Repair

Choosing Vietnam Shiprepair for Hatch Cover Repair offers peace of mind. Our Marine Service saves time, maintaining schedules at Da Nang Port. Cost-effective repairs with AH36 steel reduce expenses compared to full replacements. Our DNV-certified technicians enhance vessel safety and reputation, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Repaired hatch cover in stable operation at DA NANG.

Repaired hatch cover in stable operation at DA NANG.

Vietnam Shiprepair’s Commitment to Excellence

Our repair process ensures quality. We inspect damage, safely disassemble, reinforce with AH36 steel, and test thoroughly. We maintain IACS and IMO compliance, supervised by DNV throughout. Choose Vietnam Shiprepair for reliable Hatch Cover Repair.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

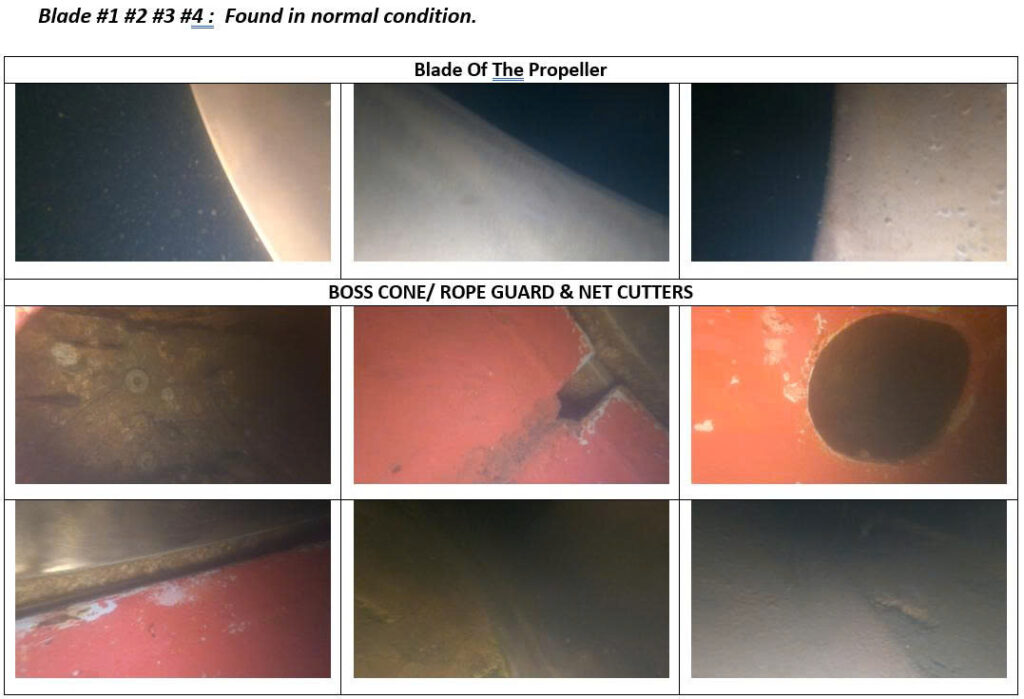

Underwater Survey at Van Phong Bay

Underwater Survey at Van Phong Bay – Expert Services by Vietnam Shiprepair

Is your vessel showing signs of underwater damage at Van Phong Bay? Vietnam Shiprepair Co. offers professional Underwater Survey, Marine Diving Services, and Marine Service, ensuring vessel safety and compliance. On September , 2025, we conducted a successful underwater inspection for a wood chip carrier at Van Phong Bay without operational delays. Our services cover all ports and anchorages across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. Our work adheres to International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust Vietnam Shiprepair for dependable solutions!

Divers preparing for an underwater survey of a vessel at Van Phong Bay.

Divers preparing for an underwater survey of a vessel at Van Phong Bay.

Importance of Underwater Surveys for Vessels

Underwater surveys are vital for maintaining vessel integrity at Van Phong Bay, especially for ships like wood chip carriers. These inspections detect corrosion, cracks, or damage to the hull, propellers, and rudders, preventing safety hazards and operational failures. A neglected underwater structure risks violating IACS and IMO regulations. Vietnam Shiprepair’s Underwater Survey ensures early detection and compliance, safeguarding your vessel’s performance.

Basic Steps for Underwater Survey Diving

Vietnam Shiprepair recently performed an Underwater Survey at Van Phong Bay due to suspected hull corrosion. Here are the key steps:

-

Identifying Signs for Survey: Look for rust stains, unusual vibrations, or changes in draft indicating underwater issues.

-

Preparation: Equip divers with SCUBA gear, ultrasonic thickness gauges, and underwater cameras; use support boats and ROVs for efficiency.

-

Underwater Process: Divers ensure safety with communication lines, record video of the hull, propellers, and rudders, and measure thickness.

-

Post-Survey Evaluation: Analyze footage, assess damage, and submit reports to classification societies like International Association of Classification Societies (IACS).

This process ensured vessel safety, but timely action is critical to avoid downtime.

Importance of Minimizing Downtime During Surveys

Conducting an Underwater Survey with minimal disruption is essential at Van Phong Bay. Delays can halt operations, causing financial losses and missed schedules. Vietnam Shiprepair prioritizes rapid Marine Diving Services, completing inspections efficiently with mobile support. Quick service also reduces exposure to marine risks, ensuring IACS and IMO compliance.

Vietnam Shiprepair’s Compliance with Underwater Surveys

A reliable service provider must meet stringent standards. Vietnam Shiprepair employs IACS-certified divers and advanced equipment, adhering to IMO and IACS protocols. Our surveys are supervised by classification societies, guaranteeing accurate assessments and regulatory compliance.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Service, including Underwater Survey, across Vietnam:

-

Van Phong Bay: Ideal for efficient inspections, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for quick Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

Analyze footage, assess damage, and submit reports to classification societies at Van Phong Bay.

Analyze footage, assess damage, and submit reports to classification societies at Van Phong Bay.

Benefits of Choosing Vietnam Shiprepair for Underwater Surveys

Choosing Vietnam Shiprepair for Underwater Survey provides peace of mind. Our Marine Diving Services save time, maintaining schedules at Van Phong Bay. Early detection reduces repair costs compared to major overhauls. Our certified divers enhance vessel safety and reputation, supported by over 20 years of experience and IACS/IMO compliance with detailed reports.

Vietnam Shiprepair’s Commitment to Excellence

Our survey process ensures quality. We identify issues, prepare with top-tier equipment, conduct safe inspections with video documentation, and evaluate thoroughly. We uphold IACS and IMO standards throughout. Choose Vietnam Shiprepair for trusted Underwater Survey.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Rubber Conveyor Belt Replacement at Quy Nhon Port

Rubber Conveyor Belt Replacement at Quy Nhon Port – Professional Services by Vietnam Shiprepair

Is your vessel’s conveyor belt worn out at Quy Nhon Port? Vietnam Shiprepair Co. provides expert Rubber Conveyor Belt Replacement, Conveyor Belt Services, and Marine Service, ensuring efficient cargo handling for wood chip carriers. On September 09, 2025, at 09:44 AM +07, we successfully replaced a rubber conveyor belt at Quy Nhon Port without disrupting loading schedules. Our services extend to all ports and anchorages across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. Our repairs comply with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust Vietnam Shiprepair for reliable solutions!

Rubber Conveyor Belt Replacement: Worn rubber conveyor belt on a wood chip carrier at Quy Nhon Port before replacement.

Rubber Conveyor Belt Replacement: Worn rubber conveyor belt on a wood chip carrier at Quy Nhon Port before replacement.

Importance of Rubber Conveyor Belts for Wood Chip Carriers

Rubber conveyor belts are crucial for wood chip carriers, facilitating the seamless loading and unloading of wood chips at Quy Nhon Port. These belts ensure continuous material flow, optimizing efficiency for this lightweight, heat-generating cargo. A worn Rubber Conveyor Belt risks slowdowns, cargo spills, or safety hazards, violating IACS and IMO standards. Vietnam Shiprepair’s Conveyor Belt Replacement restores these vital components, ensuring compliance and operational smoothness.

Basic Steps for Replacing Rubber Conveyor Belts

Vietnam Shiprepair recently replaced a Rubber Conveyor Belt at Quy Nhon Port due to excessive wear. Here are the key steps using the heat press method:

-

Sourcing Standard Materials: We procure high-quality rubber belts meeting IMO and IACS standards, reinforced with fabric or steel for durability.

-

Removing the Old Conveyor Belt: Technicians shut down the system, remove accessories, cut the old belt into sections, and dispose of it safely.

-

Installing the New Conveyor Belt: The new belt is positioned, cut to size, and joined using heat press technology—applying adhesive, heating at 140-160°C for 120-180 minutes, and cooling for 1-2 hours—ensuring a seamless connection.

-

Testing and Operation: Initial low-speed tests and load trials confirm stability, followed by full operation with continuous monitoring.

This process ensured efficient cargo handling, but timely execution is key to avoid delays.

Importance of Minimizing Downtime During Replacement

Replacing a Rubber Conveyor Belt quickly without affecting loading schedules is critical at Quy Nhon Port. Delays lead to financial losses and missed deadlines for wood chip carriers. Vietnam Shiprepair prioritizes rapid Conveyor Belt Replacement, completing tasks efficiently with workshop support. Quick service also minimizes weather-related risks, ensuring IACS and IMO compliance.

Vietnam Shiprepair’s Compliance with Conveyor Belt Replacement

A trusted repair unit must follow strict standards and certified procedures. Vietnam Shiprepair employs advanced heat press techniques, with welders and processes certified by IACS. Our work adheres to IMO and IACS guidelines, guaranteeing durable, safe conveyor belts for marine use.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Service, including Conveyor Belt Replacement, across Vietnam:

-

Quy Nhon Port: Ideal for efficient repairs, as shown recently.

-

Nghi Son Anchorage: A key hub for quick Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

Rubber Conveyor Belt Replacement: Team replacing rubber conveyor belt with heat press.

Rubber Conveyor Belt Replacement: Team replacing rubber conveyor belt with heat press.

Benefits of Choosing Vietnam Shiprepair for Conveyor Belt Replacement

Choosing Vietnam Shiprepair for Conveyor Belt Replacement offers peace of mind. Our Marine Service saves time, preserving loading schedules at Quy Nhon Port. Cost-effective replacement with high-quality Rubber Conveyor Belt reduces expenses compared to full system overhauls. Our certified technicians enhance vessel safety and reputation, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Rubber Conveyor Belt Replacement: Replaced rubber conveyor belt handling wood chips.

Rubber Conveyor Belt Replacement: Replaced rubber conveyor belt handling wood chips.

Vietnam Shiprepair’s Commitment to Excellence

Our replacement process ensures quality. We source standard materials, remove old belts safely, install new ones with heat press precision, and test thoroughly. We maintain IACS and IMO compliance throughout. Choose Vietnam Shiprepair for reliable Conveyor Belt Replacement.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Container Bridge Repair at Da Nang Port

Container Bridge Repair at Da Nang Port – Expert Services by Vietnam Shiprepair

Is your container ship’s Container Bridge damaged at Da Nang Port? Vietnam Shiprepair Co. offers expert Container Bridge Repair, Steel Works, and Marine Service, ensuring safe deck operations. On August 23, 2025, we successfully repaired a Container Bridge for a container ship at Da Nang Port without disrupting loading schedules. Moreover, our services extend to all ports and anchorages across Vietnam, including Nghi Son Anchorage, Vung Tau, and Ho Chi Minh City. Our repairs comply with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Therefore, trust Vietnam Shiprepair for dependable marine solutions!

Damaged Container Bridge on deck before repair at Da Nang Port.

Damaged Container Bridge on deck before repair at Da Nang Port.

Importance of Container Bridge for Container Ships

The Container Bridge is vital for container ships, providing a stable platform for stacking containers on the deck at Da Nang Port. This steel structure distributes weight, prevents container movement during transit, and protects the deck from damage. A compromised Container Bridge risks cargo instability, structural failure, or safety hazards, violating IACS and IMO standards. Vietnam Shiprepair’s Container Bridge Repair and Steel Works restore these components, ensuring compliance and operational efficiency.

Basic Steps for Container Bridge Repair

Vietnam Shiprepair recently repaired a Container Bridge at Da Nang Port due to safety concerns. Here are the key steps to address insufficient deck stability:

-

Inspection: Technicians assess the bridge for cracks, corrosion, and misalignment using advanced diagnostics, supervised by NK Class surveyors.

-

Disassembly: Damaged sections are removed to prepare for repair.

-

Welding and Reinforcement: Skilled welders, certified by NK Class, perform Steel Works using high-quality AH36 steel to strengthen or replace sections, adhering to IACS/IMO standards with NK Class-approved welding procedures.

-

Alignment Check: The bridge is realigned to ensure proper container support.

-

Testing: Load and stability tests verify secure deck operations, monitored by NK Class.

-

Coating: Anti-corrosion coating is applied to enhance durability.

This process ensured safe operations, but timely execution is crucial to avoid delays.

Importance of Minimizing Downtime During Repair

Repairing the Container Bridge in the shortest time possible without affecting loading schedules is vital at Da Nang Port. Delays disrupt cargo operations, leading to financial losses and missed deadlines. Vietnam Shiprepair prioritizes rapid Container Bridge Repair, completing tasks efficiently with workshop support. Moreover, quick service minimizes exposure to weather risks, ensuring IACS and IMO compliance while keeping the vessel operational.

Vietnam Shiprepair’s Compliance with Container Bridge Repair

A reputable repair unit must adhere to rigorous welding processes and IACS-certified welders. Vietnam Shiprepair meets these criteria, using advanced Steel Works techniques with AH36 steel and NK Class-certified welders. Our welding procedures are approved and inspected by NK Class, guaranteeing expertise recognized by classification societies. This compliance with IACS and IMO standards ensures repaired Container Bridges withstand marine stresses, enhancing safety during deck operations.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Service, including Container Bridge Repair, across Vietnam:

-

Da Nang Port: Ideal for efficient repairs, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for quick Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

Team performing Steel Works on Container Bridge.

Benefits of Choosing Vietnam Shiprepair for Container Bridge Repair

Selecting Vietnam Shiprepair for Container Bridge Repair ensures peace of mind. Our Marine Service saves time with rapid repairs, preserving loading schedules at Da Nang Port. Additionally, our cost-effective Steel Works with AH36 steel reduces expenses compared to full bridge replacements, optimizing your budget. Moreover, our NK Class-certified technicians deliver trusted results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IACS and IMO compliance, providing detailed reports for inspections. Contact us for efficient Vietnam Shiprepair!

Repaired Container Bridge with containers secured.

Repaired Container Bridge with containers secured.

Vietnam Shiprepair’s Commitment to Excellence

Our repair process guarantees quality. We inspect the Container Bridge for damage, supervised by NK Class. Then, we disassemble and repair with precision Steel Works using AH36 steel. After that, we test for safety. Finally, we ensure IACS/IMO compliance with NK Class oversight. Choose Vietnam Shiprepair for reliable Container Bridge Repair.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

Archives

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | 29 |

| 30 | 31 | |||||

Categories

- News (9)

- Project Updates (106)