- by Vietnam Ship Repair

- 0

Main Engine Repairs for Container Ships

Main Engine Repairs for Container Ships – Vietnam Shiprepair’s Expert Solutions at Quy Nhon Port

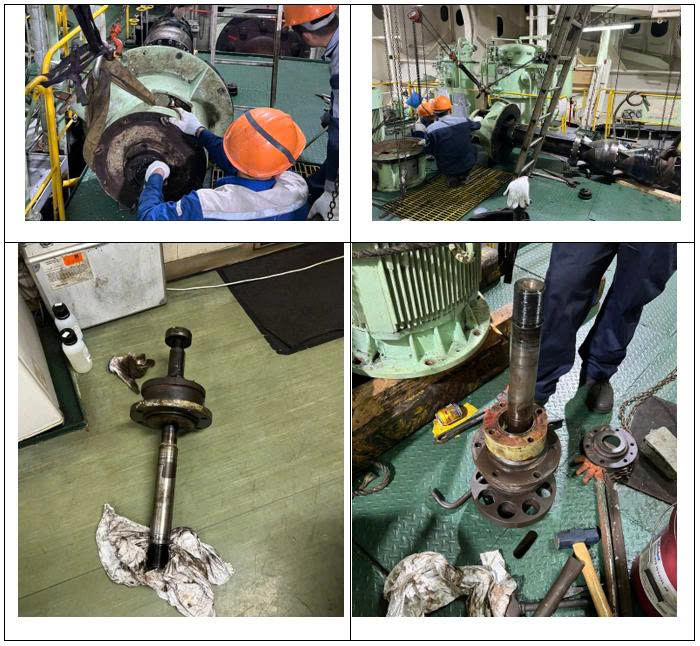

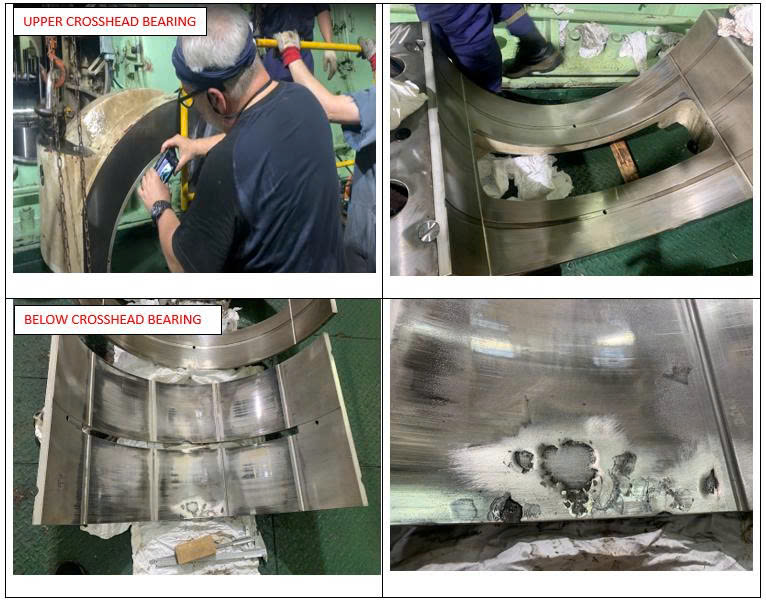

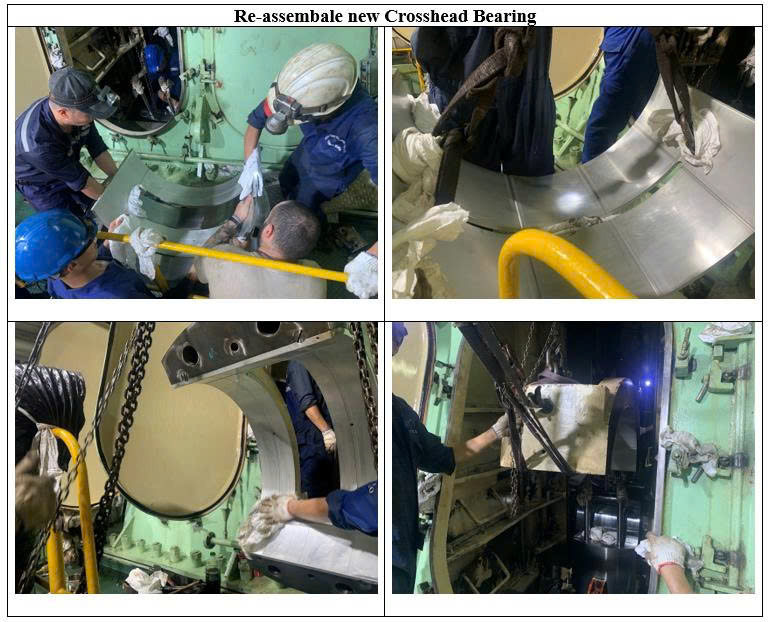

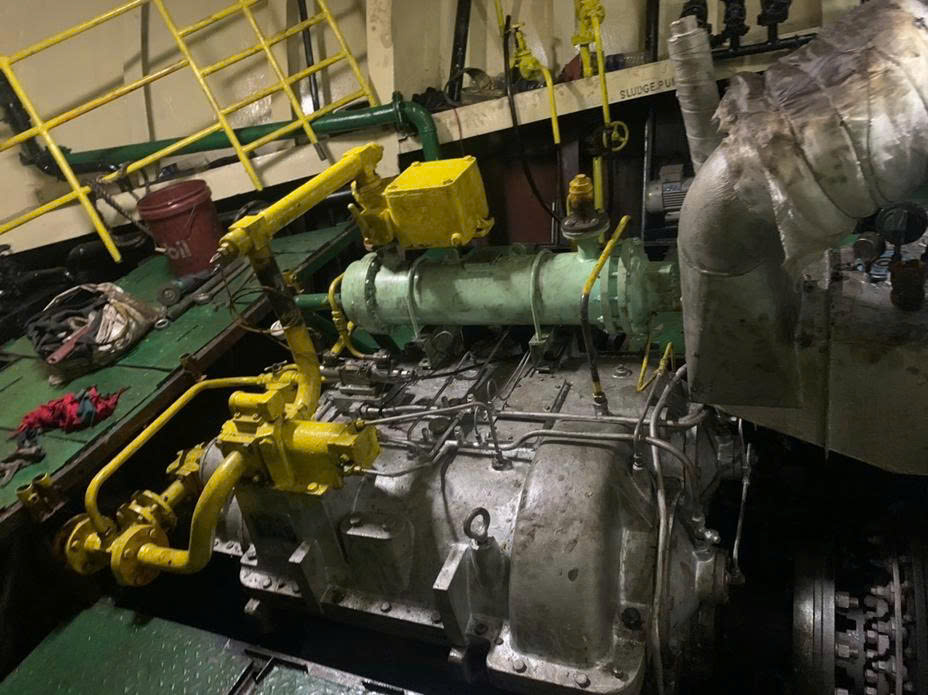

Is your container ship’s main engine facing issues at Quy Nhon Port? Vietnam Shiprepair Co. provides professional Main Engine Repairs, including crosshead bearing replacement, to restore optimal performance. On Tuesday, June 16, 2025, we successfully replaced the crosshead bearing for a container ship at Quy Nhon Port. Moreover, our Marine Services extend to all ports and anchorages across Vietnam, including Danang Port, Nghi Son Port, Vung Tau, and beyond. Our repairs comply with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards—learn more at IMO Standards. Therefore, trust Vietnam Shiprepair for reliable Main Engine Repairs nationwide!

Vietnam Shiprepair team performing main engine repairs at Quy Nhon Port

Vietnam Shiprepair team performing main engine repairs at Quy Nhon Port

Importance of Main Engine and Crosshead Bearing Functionality

The main engine is the heart of a container ship, driving propulsion and ensuring seamless operations. A malfunctioning engine, especially a damaged crosshead bearing, can halt operations at Quy Nhon Port, causing costly delays. Moreover, it jeopardizes crew safety and cargo schedules in demanding marine conditions. A functional crosshead bearing reduces friction and wear, enhancing engine efficiency and longevity. Vietnam Shiprepair’s Main Engine Repairs ensure compliance with IMO and IACS standards, keeping your vessel operational and inspection-ready. This reliability is critical for container shipping success.

Nationwide Marine Services Network

Vietnam Shiprepair delivers Marine Services, including Main Engine Repairs, across Vietnam:

- Quy Nhon Port: Perfect for efficient repairs, as shown recently.

- Danang Port: A key hub for quick Marine Services.

- Nationwide Reach: We serve Nghi Son Port, Vung Tau, and all ports and anchorages. Explore Services.

- Mobile Operations: Our team brings tools and expertise to your vessel.

- Rapid Response: Fast deployment minimizes downtime.

Vietnam Shiprepair team performing main engine repairs at Quy Nhon Port

Vietnam Shiprepair team performing main engine repairs at Quy Nhon Port

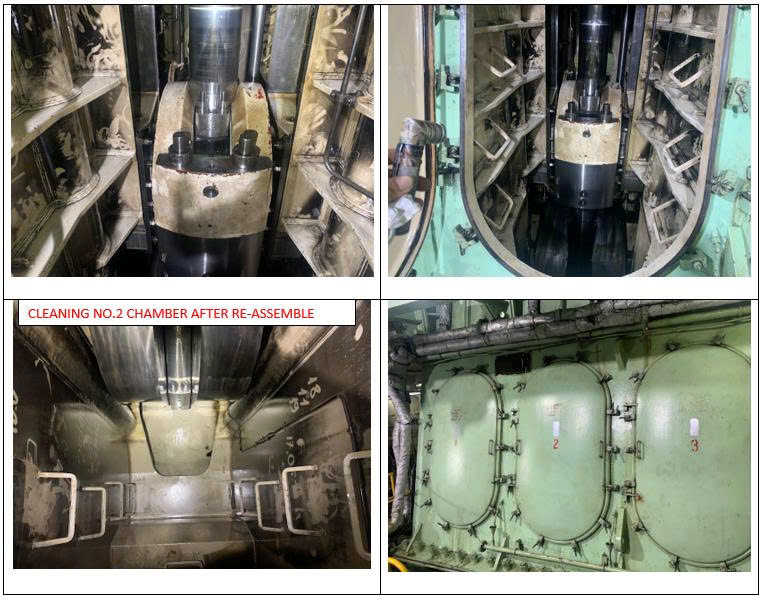

Steps to Replace a Crosshead Bearing in Main Engine Repairs

Vietnam Shiprepair recently replaced a crosshead bearing for a container ship at Quy Nhon Port. Here’s the detailed process:

- Inspection: We assessed the main engine, identifying wear and damage in the crosshead bearing.

- Disassembly: Removed the connecting rod and piston assembly to access the bearing.

- Removal: Carefully extracted the old crosshead bearing, ensuring no damage to adjacent components.

- Installation: Fitted a new bearing, aligning it precisely with manufacturer specifications.

- Reassembly: Reinstalled the piston and connecting rod, applying proper torque.

- Testing: Conducted performance tests to confirm stability and compliance with IMO/IACS standards.

This process restored the engine’s efficiency, adhering to international regulations.

Benefits of Choosing Vietnam Shiprepair for Main Engine Repairs

Selecting Vietnam Shiprepair for Main Engine Repairs ensures confidence and savings. Our Marine Services save time with rapid repairs, avoiding delays at Quy Nhon Port. Additionally, our cost-effective solutions reduce expenses compared to sourcing new parts, optimizing your budget. Moreover, our IACS-approved technicians deliver reliable results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair complies with IMO and IACS standards, providing detailed reports for inspections. Contact us for trusted Marine Services! Contact Us.

Fully repaired main engine with new crosshead bearing by Vietnam Shiprepair at Quy Nhon Port

Fully repaired main engine with new crosshead bearing by Vietnam Shiprepair at Quy Nhon Port

Why Vietnam Shiprepair Excels in Marine Services

Vietnam Shiprepair stands out for Main Engine Repairs and Marine Services:

- Expert Technicians: Skilled professionals with deep marine expertise.

- Fast Turnaround: Quick response at Quy Nhon Port and all ports.

- Customized Solutions: Tailored repairs for each vessel’s needs.

- Global Compliance: Adherence to IMO and IACS standards.

- Cost Efficiency: Competitive pricing with high-quality outcomes.

- Nationwide Coverage: Services across Danang, Nghi Son, Vung Tau, and more.

Our dedication ensures your container ship remains operational. Reach out today!

Vietnam Shiprepair’s Commitment to Quality

Our repair process guarantees excellence. We inspect engines for damage. Then, we disassemble to access faulty parts. After that, we replace components with precision. Finally, we test to ensure IMO/IACS compliance. Choose Vietnam Shiprepair for superior Main Engine Repairs.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

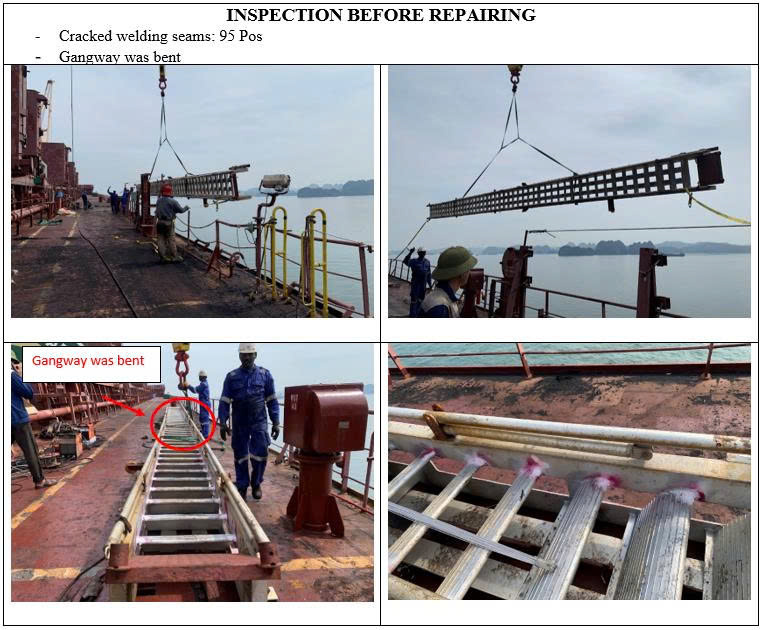

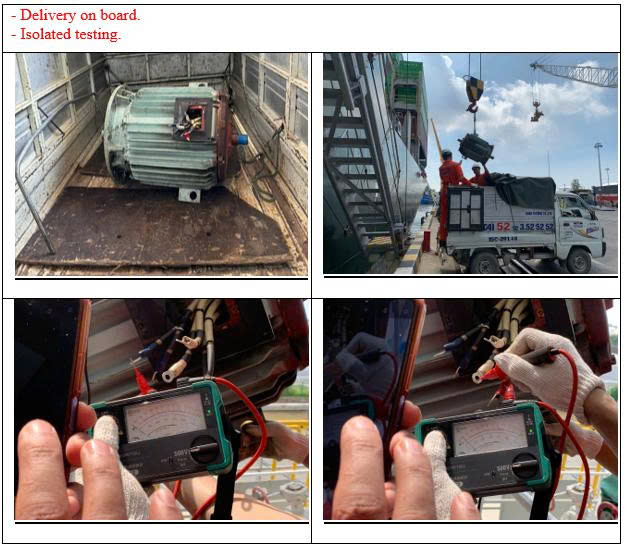

Accommodation Ladder Repairs at Van Phong Bay

Accommodation Ladder Repairs at Van Phong Bay – Expert Marine Services by Vietnam Shiprepair

Is your vessel’s accommodation ladder damaged at Van Phong Bay? Vietnam Shiprepair Co. offers professional Accommodation Ladder Repairs and comprehensive Marine Service solutions to restore safety and functionality. June 20, 2025, we successfully repaired an aluminum accommodation ladder for a vessel at Van Phong Bay. Moreover, we extend our Marine Service to all anchorages and ports across Vietnam, including Danang Port, Nghi Son Port, Vung Tau, and beyond. Our repairs comply with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards—learn more at IMO Standards. Therefore, trust Vietnam Shiprepair for reliable Accommodation Ladder Repairs nationwide!

Inspecting an accommodation ladder at Van Phong Bay

Inspecting an accommodation ladder at Van Phong Bay

Importance of Repairing Accommodation Ladders Over Replacement

Repairing an accommodation ladder, rather than replacing it, offers significant advantages for vessels at Van Phong Bay. First, repairs save time, often completing within days compared to weeks for a new installation. Additionally, they reduce costs by up to 60% compared to purchasing a new ladder, making it a budget-friendly option. Moreover, repairing preserves the original design, avoiding compatibility issues with existing vessel structures. A damaged ladder, if unrepaired, poses safety risks to crew and inspectors during boarding. Vietnam Shiprepair’s Accommodation Ladder Repairs ensure compliance with IMO and IACS safety standards, enhancing vessel accessibility without the expense of replacement.

Nationwide Marine Service Network

Vietnam Shiprepair delivers Marine Service, including Accommodation Ladder Repairs, across Vietnam:

- Van Phong Bay: Ideal for efficient repairs, as demonstrated recently.

- Danang Port: A hub for quick Marine Service solutions.

- Nationwide Reach: We serve Nghi Son Port, Vung Tau, and all anchorages and ports. Explore Services.

- Mobile Operations: Our team brings tools and expertise directly to your vessel.

- Rapid Response: Fast deployment minimizes downtime.

Repairing In Progress

Repairing In Progress

Steps to Repair an Aluminum Accommodation Ladder with Corrosion and Cracks

Vietnam Shiprepair recently repaired an aluminum accommodation ladder with corrosion and cracked steps at Van Phong Bay. Here’s the process:

- Inspection: We assessed the ladder for corrosion and cracks, identifying affected steps.

- Cleaning: Removed rust and debris using specialized tools to prepare the surface.

- Welding and Reinforcement: Welded cracked areas and reinforced weak spots with high-strength aluminum patches.

- Surface Treatment: Applied anti-corrosion coating to prevent future damage, adhering to IMO/IACS standards.

- Testing: Conducted load and stability tests to ensure safety and compliance.

This meticulous approach restored the ladder’s integrity, meeting international regulations while saving time and resources.

Benefits of Choosing Vietnam Shiprepair for Accommodation Ladder Repairs

Selecting a trusted provider like Vietnam Shiprepair for Accommodation Ladder Repairs ensures peace of mind. Our Marine Service saves time with rapid repairs, avoiding lengthy delays at Van Phong Bay. Additionally, our cost-effective solutions reduce expenses compared to replacement, optimizing your budget. Moreover, our IACS-approved technicians deliver reliable results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair complies with IMO and IACS standards, providing detailed reports for inspections. Contact us for efficient Marine Service! Contact Us.

Fully repaired/reinstalled accommodation ladder by Vietnam Shiprepair at Van Phong Bay

Fully repaired/reinstalled accommodation ladder by Vietnam Shiprepair at Van Phong Bay

Why Vietnam Shiprepair Stands Out

Vietnam Shiprepair is Vietnam’s leading choice for Accommodation Ladder Repairs and Marine Service:

- Expert Team: Skilled technicians with extensive marine experience.

- Quick Turnaround: Fast service at Van Phong Bay and all ports.

- Customized Solutions: Tailored repairs for each vessel’s needs.

- Global Compliance: Adherence to IMO and IACS standards.

- Cost Savings: Competitive pricing with high-quality outcomes.

- Nationwide Coverage: Services across Danang, Nghi Son, Vung Tau, and more.

Our commitment ensures your vessel remains safe and operational. Reach out today!

Vietnam Shiprepair’s Commitment to Excellence

Our repair process guarantees quality. We inspect ladders for damage. Then, we clean and reinforce affected areas. After that, we apply protective coatings. Finally, we test to confirm IMO/IACS compliance. Choose Vietnam Shiprepair for trusted Accommodation Ladder Repairs.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

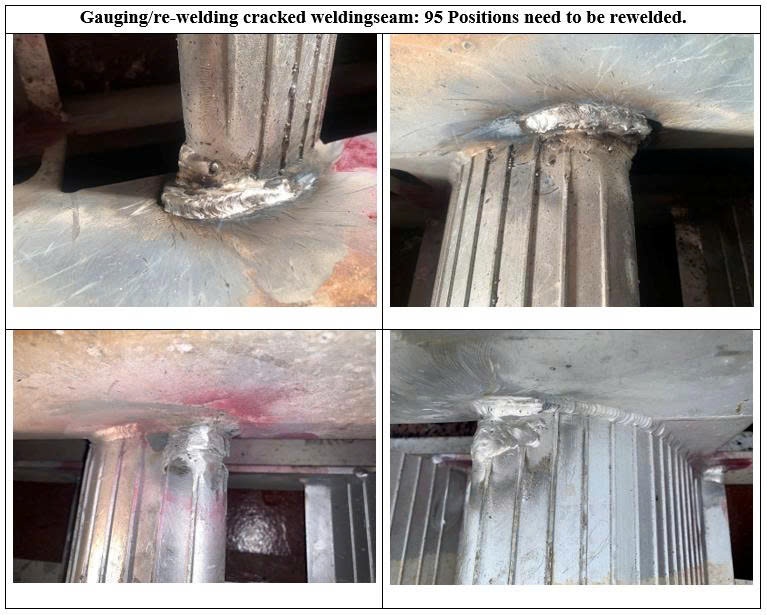

Motor Rewinding at Vung Tau Port

Motor Rewinding at Vung Tau Port – Performed by VietNam ShipRepair

When a container ship’s Main Engine Lubrication Oil (M.E L.O) pump motor fails, operations are severely impacted. At Vung Tau Port, the expert technicians from VietNam ShipRepair recently executed a complete Motor Rewinding of a damaged M.E L.O pump motor on a container vessel. This service ensures the continuous circulation of oil, maintaining engine performance and avoiding major failures.

In addition, we offer these services throughout Vietnam’s key ports and anchorages, including Da Nang, Nghi Son, Ho Chi Minh City, and more. Furthermore, our processes meet the strict international standards set by IMO and IACS, guaranteeing high-quality and safe marine repairs.

Motor Rewinding: Damaged motor disassembled at workshop

Motor Rewinding: Damaged motor disassembled at workshop

Why the M.E L.O Pump Motor Is Critical in Marine Operations

The Main Engine Lubrication Oil Pump operates using a high-efficiency electric motor, essential for distributing lubrication oil to engine components such as bearings, pistons, and the crankshaft. Consequently, when this motor breaks down, lubrication is interrupted, risking overheating and serious mechanical failure.

Therefore, scheduled inspections and timely rewinding of motors are critical for sustaining engine integrity. A well-maintained motor reduces the chance of sudden breakdowns and prolongs the vessel’s operating life.

Common Causes That Require Motor Rewinding

Marine motors endure demanding conditions that often lead to:

- Thermal degradation of insulation

- Moisture intrusion causing short circuits

- Overload or voltage imbalance

- Excessive vibration damage

As a result, motor rewinding becomes essential when insulation resistance declines or the motor stops functioning. Rewinding restores the motor to its original performance at a lower cost than full replacement.

Step-by-Step Motor Rewinding Process by VietNam ShipRepair

Our certified marine electricians follow a standardized, efficient rewinding workflow:

1. Preliminary Inspection and Diagnosis

Initially, the motor undergoes electrical and visual testing. We assess insulation resistance (IR), continuity, and phase imbalance.

2. Disassembly and Cleaning

After disassembly, we remove all windings. Then, we clean the stator and rotor thoroughly to eliminate dirt and carbon deposits.

3. Winding Replacement

Using OEM-grade copper wires, our team rewinds the stator according to the original specifications. In addition, new insulating materials are applied.

4. Resin Varnishing and Curing

Windings are coated with marine-grade resin and oven-cured under controlled conditions to increase longevity and resistance.

5. Assembly and Testing

Next, we reassemble the motor and test for insulation strength, high-voltage resistance, and balance to ensure full functionality.

6. Onboard Installation and Commissioning

Once the motor is returned to the vessel, our engineers install it, connect it to the M.E L.O pump, and conduct full operational trials.

Motor Rewinding: New copper winding being installed

Motor Rewinding: New copper winding being installed

Technical Compliance and Safety Standards

We ensure that all procedures follow key international benchmarks:

- Voltage tolerance within ±5%

- Winding imbalance below 1%

- Insulation class: F or H

- IEC/IEEE testing compliance

- Full certification as per IACS, IMO, and shipowner requirements

Detailed reports and compliance certificates are available upon request.

Motor Rewinding: Completed motor being tested onboard

Motor Rewinding: Completed motor being tested onboard

Where We Provide Our Services

Though this project was carried out at Vung Tau Port, we regularly deliver Motor Rewinding services at locations such as:

- Da Nang Port

- Thi Vai – Cai Mep Port

- Nghi Son Anchorage

- Cam Pha and Hai Phong

- Ho Chi Minh City

Moreover, we are equipped to dispatch our mobile teams nationwide with short notice.

Why Choose VietNam ShipRepair

Partnering with VietNam ShipRepair means choosing:

- 24/7 nationwide service availability

- Certified marine electricians with years of experience

- OEM-standard parts and components

- Transparent documentation for class inspections

- Service warranty for peace of mind

We combine speed, expertise, and professionalism to support your vessel wherever you are.

Get in Touch

Looking for trusted Motor Rewinding or Marine Service solutions in Vietnam?

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

M.E L.O Pump Repairs for Container Ship at Vung Tau Port

M.E L.O Pump Repairs for Container Ship at Vung Tau Port – Performed by VietNam ShipRepair

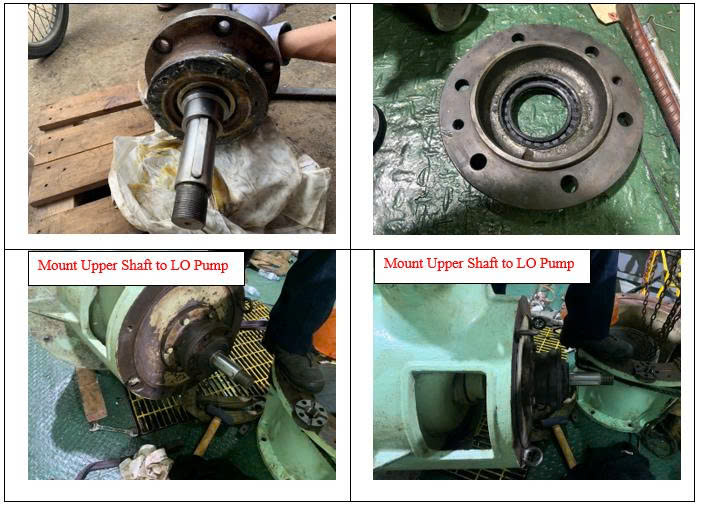

Ensuring the efficient operation of a container ship requires precise attention to its main engine components. One of the most vital among these is the Main Engine Lubrication Oil Pump (M.E L.O Pump). At Vung Tau Port, VietNam ShipRepair recently completed a comprehensive M.E L.O Pump Repairs/Main Engine Service, which included replacing the Upper Shaft and Bearing Housing completed set of a container ship’s L.O pump.

This essential service is available not only in Vung Tau but also across all ports and anchorages in Vietnam, including Da Nang, Nghi Son, Ho Chi Minh City, and others. With a professional team and strict adherence to international standards such as IMO and IACS, VietNam ShipRepair delivers dependable service and complete peace of mind.

The Importance of the Main Engine Lubrication Oil Pump

The L.O pump plays a crucial role in ensuring consistent lubrication throughout the engine. It maintains the oil flow to key components, such as pistons, bearings, and the crankshaft. Consequently, the pump reduces friction, minimizes wear, and supports a stable operating temperature.

A malfunctioning pump can lead to overheating, component seizure, and severe engine failure. Therefore, regular M.E L.O Pump Repairs are essential to prevent breakdowns and ensure vessel safety.

Why Periodic Maintenance and M.E L.O Pump Repairs Are Necessary

Even durable pumps experience wear over time. Early indicators like abnormal noise, pressure drops, or metal particles in filters signal potential failures.

For instance, in our recent repair project, such symptoms prompted a full replacement of the Upper Shaft and Bearing Housing. Timely action prevented further engine damage and minimized operational downtime.

Moreover, consistent maintenance practices extend equipment life and reduce unexpected repair costs.

Replacement of bearing housing and upper shaft in progress

Step-by-Step Repair Procedure

To deliver consistent quality, VietNam ShipRepair implements a standardized repair process:

1. Initial Diagnosis and Inspection

We begin by disconnecting the pump from the engine. Our team measures shaft tolerances and bearing clearances while analyzing oil samples.

2. Disassembly

Next, we disassemble the pump and remove the worn upper shaft and damaged bearing housing.

3. Workshop Preparation

In our fabrication workshop, new parts are prepared and machined to exact alignment specifications. In addition, we replace seals and gaskets, then clean and balance the components.

4. Installation Onboard

After the components pass inspection, we reinstall the pump onboard. Our engineers perform rotation and pressure tests to verify performance.

5. Final Testing and Reporting

We conduct engine trials under load to confirm functionality. Finally, we deliver a detailed report, including photos and test logs, to the shipowner.

Technical Requirements and Standards

Repairs by VietNam ShipRepair consistently meet rigorous international standards:

- Shaft runout: < 0.03 mm

- Oil pressure (idle/load): OEM-specific

- Alignment tolerance: Within 0.02 mm

- Vibration: Within ISO/ABS limits

- Lubrication oil: OEM-grade, filtered and verified

All procedures comply with IMO and IACS standards, ensuring classification approval and long-term reliability.

M.E L.O Pump Repairs: Completed pump tested with pressure gauge before final approval

Our Service Coverage in Vietnam

Although this repair took place at Vung Tau Port, we operate nationwide with the same high standards at:

- Da Nang Port

- Nghi Son Terminal

- Ho Chi Minh Port

- Thi Vai – Cai Mep Complex

- Cam Pha and Cua Lo Anchorages

Regardless of your ship’s location, our mobile service teams are ready to provide quick and efficient assistance.

Why Choose VietNam ShipRepair?

Selecting a reliable marine repair service provider reduces downtime and enhances vessel performance. VietNam ShipRepair offers:

- 24/7 nationwide service

- Certified engineers and technicians

- OEM-quality parts and tools

- Comprehensive documentation and transparency

- Full compliance with international regulations

In short, we help shipowners save time, reduce costs, and maintain vessel integrity.

Get in Touch

Do not wait for failure to strike. For both emergency support and scheduled services, contact VietNam ShipRepair today.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

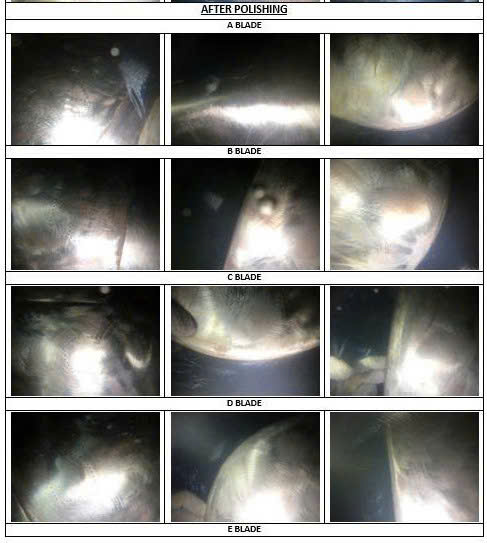

Gear Box Repairing for Main Engine at Van Phong Bay

Gear Box Repairing for Main Engine at Van Phong Bay– Expert Services by VietNam ShipRepair

A vessel’s main engine gear box is a vital component that transfers power to the propulsion system. Specifically, the clutch system inside the gearbox allows smooth engagement and disengagement between the engine and the propeller shaft. When the clutch malfunctions, the ship’s mobility and safety are compromised. That’s why gear box repairing is not optional—it’s essential.

At Vinh Van Phong Anchorage, and across key Vietnamese ports including Da Nang, Nghi Son, Vung Tau, and Ho Chi Minh City, VietNam ShipRepair provides reliable main engine service, specializing in gearbox repair and clutch replacement. Our team of certified marine engineers ensures quick turnaround and adherence to international standards like IMO and IACS.

Damaged clutch assembly removed at Van Phong Bay

Damaged clutch assembly removed at Van Phong Bay

Why the Gear Box Repairing Is Critical

The gearbox connects the main engine to the propeller shaft. Without it, ships cannot navigate or maneuver efficiently. It performs several critical functions:

-

Transfers torque from the engine to the shaft

-

Enables controlled speed reduction

-

Provides directional control (forward and reverse)

-

Protects the engine from overload via the clutch system

As a result, any failure in the gearbox—especially the clutch—can result in sudden loss of propulsion, grounding risk, or even engine damage. Therefore, regular gear box repairing and preventive maintenance are necessary for uninterrupted operations.

Common Signs That Gear Box Repairing Is Needed

Early detection can save time and money. Watch out for these warning signs:

-

Delayed or failed clutch engagement

-

Vibration or noise during transmission shifts

-

Gear slippage under load

-

Excessive oil leakage from gearbox housing

-

Overheating or abnormal temperature spikes

Ignoring these issues may lead to catastrophic failure. On the other hand, timely service ensures safer voyages and extends the gearbox’s service life.

How VietNam ShipRepair Handles Gearbox and Clutch Replacement

Our technicians use a proven and professional process for gear box repairing and clutch assembly replacement:

1. Pre-Inspection & Damage Assessment

-

Visual inspection and thermal imaging

-

Oil sampling for contamination detection

-

Functionality checks of clutch plates, bearings, and gear teeth

2. Onsite Removal & Disassembly

-

Isolation of the gear box from the main engine

-

Dismantling of clutch housing, gear shafts, and seals

-

Identification of worn-out parts for replacement

3. Installation of New Clutch Assembly

-

Precision alignment of clutch plates and pressure systems

-

Balancing of shafts and internal components

-

Application of torque settings per manufacturer’s specs

4. Final Testing and Commissioning

-

Functionality tests at idle and under load

-

Pressure and temperature monitoring

-

Submission of repair report and IMO/IACS compliance documentation

All work is carried out under strict safety guidelines and quality assurance protocols.

Technicians aligning new clutch assembly during gear box repairing

Technicians aligning new clutch assembly during gear box repairing

Workshop Support & Spare Parts

We operate a fully equipped fabrication and repair workshop that supports custom machining, cleaning, and testing of gear box components. If needed, we can fabricate temporary bypass shafts or couplings to restore operations while permanent parts are sourced.

Spare parts used are always class-approved, and we maintain working relationships with OEMs and part distributors worldwide. This reduces waiting time and increases repair efficiency.

Nationwide Coverage – Not Just at Vinh Van Phong

Although this case involves Vinh Van Phong Anchorage, our mobile repair teams are available 24/7 at:

-

Da Nang Port

-

Nghi Son Terminal

-

Vung Tau Anchorage

-

Ho Chi Minh Port, and more

Wherever your vessel is located, VietNam ShipRepair can respond quickly and effectively.

Why Choose VietNam ShipRepair?

Here’s why dozens of shipping companies rely on our main engine services and gear box repairing solutions:

-

Certified Expertise: Our engineers are trained by global OEMs and certified by class societies

-

Full Compliance: We follow guidelines from IMO, IACS, and flag state regulators

-

Time-Efficient: We aim to complete repairs within anchorage timeframes

-

Transparent Pricing: No hidden costs, full breakdown provided

-

Customer Satisfaction: We provide warranty-backed services and after-repair support

Completed gearbox testing and certification after main engine service

Completed gearbox testing and certification after main engine service

Additional Services from VietNam ShipRepair

Besides gear box and clutch repairs, we offer:

-

Underwater cleaning and propeller polishing

-

Sea valve and pipe replacement

-

Ballast and bilge system overhauls

-

Steel structure fabrication and welding

-

Electrical fault tracing and automation tuning

Schedule Your Gearbox Repair at Vinh Van Phong Today

Don’t wait for a full breakdown. If your bulk carrier shows signs of gear malfunction, book gear box repairing service with VietNam ShipRepair at Vinh Van Phong Anchorage or any port in Vietnam.

📞 Contact us now for a free technical consultation or to schedule an emergency service visit. Your ship’s uptime and safety are our mission.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Piping Replacement at Cam Pha Anchorage

Piping Replacement at Cam Pha Anchorage – Professional Fabrication by VietNam ShipRepair

The piping replacement of seawater cooling systems is a critical maintenance operation for any sea-going vessel. These pipes are exposed to corrosive environments, biological growth, and extreme pressure differences. Therefore, replacing deteriorated piping systems is not just routine—it’s vital to operational safety.

At Cam Pha Anchorage, and across major Vietnamese ports including Da Nang, Nghi Son, Vung Tau, and Ho Chi Minh City, VietNam ShipRepair delivers expert piping replacement services. Our in-house fabrication workshop guarantees precision-made parts, while our certified technicians ensure quick, compliant installation on site.

Corroded seawater cooling pipe removed from a ship at Cam Pha Anchorage for Piping Replacement

Corroded seawater cooling pipe removed from a ship at Cam Pha Anchorage for Piping Replacement

Why the Seawater Cooling System Matters

To begin with, a ship’s seawater cooling system plays a vital role in regulating the engine’s temperature. Without an efficient pipe network, heat cannot dissipate effectively. As a result:

-

Overheating can damage main and auxiliary engines

-

Fuel efficiency drops due to poor thermal control

-

Non-compliance with IMO emission standards may occur

-

Crew safety and voyage reliability are compromised

Because seawater pipes are constantly exposed to salt, vibration, and temperature changes, regular maintenance and timely replacement are essential.

When Should You Replace These Pipes?

In many cases, ships operate with pipes that show early signs of failure. However, waiting until a leak or blockage occurs can lead to costly delays or emergency docking.

You should consider piping replacement when:

-

Pipe walls show signs of thinning or corrosion

-

Flow rates drop due to biofouling or scaling

-

Seals fail and small leaks appear

-

The system fails pressure or visual inspections

Replacing these components before failure ensures operational continuity and minimizes downtime.

How VietNam ShipRepair Does It – From Workshop to Onboard Installation

At VietNam ShipRepair, we manage the entire replacement process. Our dedicated fabrication workshop handles all pipe cutting, shaping, and welding under stringent quality control.

Workshop Fabrication Includes:

-

Selection of marine-grade materials (steel or copper-nickel)

-

Bending and forming using CNC machines

-

Welding under 2G, 3G, and 6G positions

-

Surface treatments and corrosion protection

-

Dimensional and pressure testing prior to installation

These steps ensure a seamless fit and long-lasting durability.

Onboard Installation Includes:

-

Safe removal of old pipes and cleanup of fittings

-

Proper alignment of new sections

-

High-quality welds using certified processes

-

Hydrostatic testing and leak verification

-

Final sign-off with class documentation

Every job strictly follows international standards set by IMO, IACS, and respective class societies like DNV, BV, or ABS.

Fabrication process of seawater cooling pipes for Piping Replacement

Fabrication process of seawater cooling pipes for Piping Replacement

Nationwide Support – Not Just at Cam Pha Anchorage

Although this project highlights Cam Pha, our services are available at all major ports and anchorages in Vietnam:

-

Da Nang Port

-

Nghi Son Terminal

-

Vung Tau Anchorage

-

Ho Chi Minh Port, and more

Our mobile repair teams and fabrication logistics allow us to support vessels quickly and efficiently, regardless of location.

Why Choose VietNam ShipRepair?

Partnering with VietNam ShipRepair means choosing a service provider that understands the needs of modern shipping. Here’s what makes us a trusted name in the industry:

-

Certified Technicians: All welders are trained in 2G, 3G, and 6G welding, following ASME and IACS codes.

-

Compliance & Safety: Every job meets the latest IMO environmental and safety regulations.

-

Transparent Process: We provide full inspection reports, test results, and documentation for class surveyors.

-

Quick Turnaround: Our workshop-fabricated pipes reduce time spent at port.

-

Cost-Efficient: Quality work done right the first time prevents future failures and saves money in the long run.

Piping Replacement of new seawater cooling pipes by VietNam ShipRepair technicians

Piping Replacement of new seawater cooling pipes by VietNam ShipRepair technicians

Additional Ship Repair Services

Besides piping replacement, we also offer:

-

Underwater cleaning & propeller polishing

-

Sea valve repairs and overhauls

-

Hull steelwork and structural fabrication

-

UWILD inspections and underwater welding

-

Ballast and bilge system maintenance

Explore our full list of services at our official website or contact our support center.

Book a Certified Piping Replacement at Cam Pha Today

Prevent unplanned downtime and ensure your vessel operates safely. Our piping replacement service at Cam Pha Anchorage is designed for speed, precision, and full regulatory compliance. Whether you’re docked or anchored, our crew can assist immediately.

📞 Contact VietNam ShipRepair to request a free quote or arrange a site inspection. Our engineers are on standby 24/7 to keep your fleet moving.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Vent Duct Replacement for Container Ships at Ho Chi Minh Port

Vent Duct Replacement at Ho Chi Minh Port – Quality Fabrication and Installation by VietNam ShipRepair

Proper ventilation inside cargo holds plays a critical role in protecting goods and ensuring the safety of container vessels. Over time, ventilation systems—especially vent ducts—can corrode, deform, or lose efficiency due to harsh maritime conditions. To maintain optimal performance, timely vent duct replacement is essential.

At Ho Chi Minh Port, as well as across other major Vietnamese ports such as Da Nang, Nghi Son, and Vung Tau, VietNam ShipRepair provides professional vent duct fabrication and installation services. Our solutions meet the latest IMO and IACS standards, ensuring safety, efficiency, and compliance.

Technicians inspecting damaged vent ducts onboard

Technicians inspecting damaged vent ducts onboard

Why Vent Ducts Matter in Cargo Hold Operations

Cargo holds must remain dry, ventilated, and safe throughout the voyage. The ventilation duct system ensures air circulates properly, reducing the risks of:

-

Moisture buildup and condensation

-

Corrosion of cargo structures

-

Growth of mold or bacteria

-

Accumulation of harmful gases

In addition, proper airflow helps regulate temperature, especially when transporting temperature-sensitive goods. For these reasons, shipping companies cannot afford to overlook damaged or outdated vent ducts.

Our Proven Approach: From Fabrication to Installation

At VietNam ShipRepair, we don’t just install pre-made parts. Instead, we custom-fabricate every vent duct to match each vessel’s layout, using marine-grade materials and precision engineering.

🔧 Fabrication in Our Workshop

Our fabrication workshop in Ho Chi Minh City operates with modern tools and skilled technicians. Here’s how we guarantee quality:

-

Material Selection: We use galvanized or marine-grade stainless steel for superior corrosion resistance.

-

Precision Engineering: All ducts are cut, shaped, and welded according to the ship’s dimensions.

-

Protective Coatings: A high-durability anti-corrosion layer is applied after fabrication.

-

Quality Checks: Every component passes through rigorous inspection before leaving the workshop.

🛠 Onboard Installation at Port

After fabrication, our team handles installation directly at Ho Chi Minh Port or wherever your vessel is docked. The process includes:

-

Removal of old, damaged ducts

-

Fitting and alignment of new components

-

Sealing, bolting, and welding as required

-

Final airflow and leak testing

Throughout the installation, we maintain open communication with the ship’s technical team to avoid disruption and meet port schedule constraints.

In the VietNam ShipRepair workshop for vent ducts replacement

In the VietNam ShipRepair workshop for vent ducts replacement

Locations Served: Not Just Ho Chi Minh Port

Although we are based at Ho Chi Minh Port, our mobile response teams and fabrication capacity allow us to serve vessels at all major Vietnamese ports and anchorages, including:

-

Da Nang Port

-

Nghi Son Port

-

Vung Tau Anchorage

-

Quy Nhon, Hai Phong, and more

Why Choose VietNam ShipRepair for Vent Duct Replacement?

In addition to vent duct replacement, we offer a wide range of onboard and underwater services including: Finding a reliable partner for critical ship repairs is key to minimizing downtime and ensuring regulatory compliance. Here’s why VietNam ShipRepair is a top choice:

✅ International Compliance

All work meets the standards of IMO, IACS, and relevant classification societies.

✅ Experienced Engineers

Our fabrication and repair teams have extensive experience with various ship types, including bulk carriers, tankers, and container ships.

✅ On-Time Delivery

We understand the importance of schedule adherence in maritime logistics. All projects are executed within tight turnaround times.

✅ Full Documentation

We provide reports, drawings, certifications, and post-installation test results for easy submission to port authorities or class surveyors.

By offering both fabrication workshop services and on-site installation, we provide end-to-end solutions that reduce costs and streamline repair timelines.

Vent ducts replacement are replacing in a container ship

Vent ducts replacement are replacing in a container ship

Beyond Vent Ducts – Complete Ship Repair Services

In addition to vent duct replacement, we offer a wide range of onboard and underwater services including:

-

Hull & structural repairs

-

Pipe fabrication & replacement

-

Anode installation

-

Underwater cleaning and propeller polishing

-

UWILD inspections and underwater welding

By offering both fabrication workshop services and on-site installation, we provide end-to-end solutions that reduce costs and streamline repair timelines.

Book Your Vent Duct Replacement Service Today

If your vessel requires vent duct replacement at Ho Chi Minh Port or any other port in Vietnam, choose a name trusted by shipowners and operators worldwide — VietNam ShipRepair. Our experienced team, precision fabrication methods, and international compliance guarantee long-lasting, reliable results.

📞 Contact us now for a free consultation or to schedule service. Our team is available 24/7 to support your ship repair needs.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

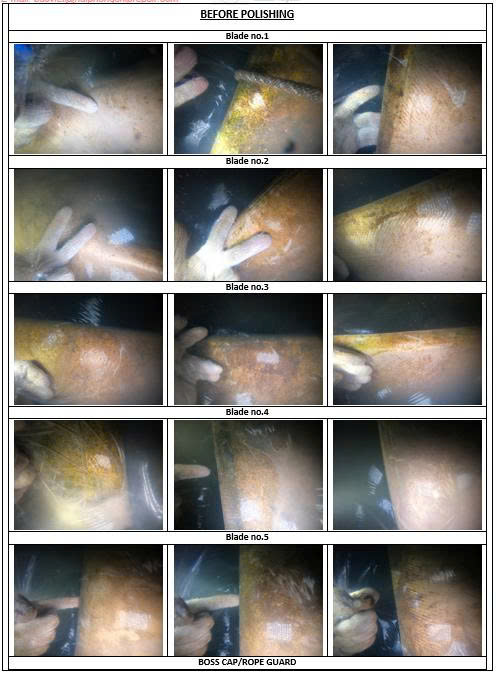

Propeller Polishing at Da Nang Port

Polishing at Da Nang Port

June 04, 2025, and your container ship is docked at Da Nang Port. The propeller is fouled with marine growth, reducing efficiency and risking costly repairs. Vietnam ShipRepair provides expert Underwater Cleaning and Propeller Polishing, serving Da Nang Port and across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. Our services ensure your vessel operates smoothly and meets global standards.

A Vietnam ShipRepair diver inspecting a fouled propeller at Da Nang Port.

A Vietnam ShipRepair diver inspecting a fouled propeller at Da Nang Port.

The Vital Importance of Propeller Polishing for Container Ships

Propeller polishing is critical for container ships, maintaining propeller efficiency by removing marine growth and corrosion. At Da Nang Port, where vessels face constant exposure to seawater, a fouled propeller increases fuel consumption, reduces speed, and strains the engine, potentially leading to mechanical failures. Regular Underwater Cleaning and Propeller Polishing prevent these issues, ensuring compliance with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards, while safeguarding vessel performance.

Benefits of Propeller Polishing and Underwater Cleaning

Investing in Underwater Cleaning and Propeller Polishing offers significant operational and economic benefits:

-

Improved Vessel Efficiency: Polished propellers reduce drag, lowering fuel use and enhancing speed at Nghi Son or Vung Tau.

-

Prevention of Damage: Regular cleaning prevents corrosion and mechanical strain, avoiding expensive repairs.

-

Cost Savings: Timely maintenance reduces the risk of major breakdowns, saving on long-term costs.

-

Regulatory Compliance: Adherence to IMO and IACS standards ensures your vessel passes inspections.

Vietnam ShipRepair’s expertise maximizes efficiency, prevents damage, and ensures compliance. Learn more about IMO guidelines here.

Vietnam ShipRepair team performing Propeller Polishing at Ho Chi Minh City port.

Vietnam ShipRepair team performing Propeller Polishing at Ho Chi Minh City port.

Our Underwater Cleaning and Propeller Polishing Process

Vietnam ShipRepair follows a precise process for Underwater Cleaning and Propeller Polishing, ensuring quality and compliance:

-

Initial Inspection: Divers assess propeller condition underwater using specialized equipment.

-

Cleaning and Polishing: We remove marine growth and polish the propeller with marine-grade tools.

-

Quality Check: Engineers verify smoothness and alignment, adhering to IMO and IACS standards.

-

Final Deployment: The propeller is reinstalled, ready for use at Da Nang Port.

This process guarantees optimal performance across Vietnam. Visit Vietnam ShipRepair Services for more details.

Why Vietnam ShipRepair is Your Trusted Partner

With over 20 years of experience, Vietnam ShipRepair excels in maritime solutions. We provide Underwater Cleaning and Propeller Polishing at:

-

Da Nang Port

-

Nghi Son Port and Anchorage

-

Vung Tau Anchorage

-

Ho Chi Minh City Ports and Anchorage

Our workshops and dive teams in Hai Phong and Ho Chi Minh City use advanced technology, ensuring IMO and IACS compliance. Ship operators trust our reliability and nationwide coverage for peace of mind.

A polished propeller in action at Vung Tau port. Alt text: Polished propeller on container ship.

A polished propeller in action at Vung Tau port. Alt text: Polished propeller on container ship.

Enhance Your Voyage with Vietnam ShipRepair

Don’t let a fouled propeller hinder your operations. Choose Vietnam ShipRepair for expert Underwater Cleaning and Propeller Polishing at Da Nang Port and beyond. Contact us now at 05:15 PM on June 04, 2025, to schedule your service and ensure a more efficient, damage-free journey.

Choose Vietnam Shiprepair for efficient, reliable Underwater Cleaning and Propeller Polishing that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

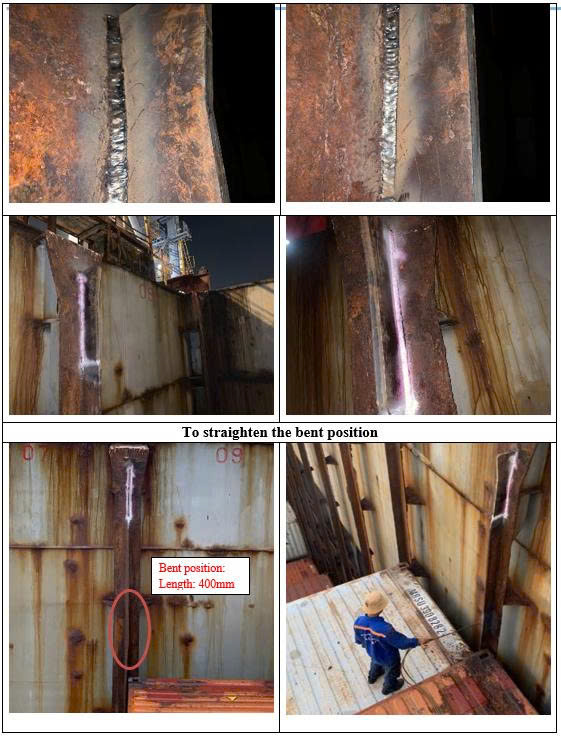

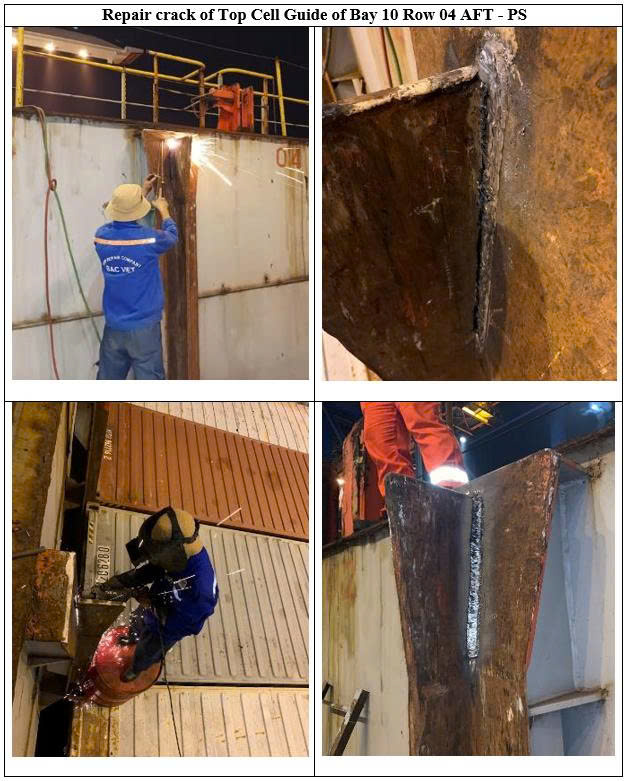

Cell Guide Repair for Container Ships at Da Nang Port

Cell Guide Repair for Container Ships at Da Nang Port

It’s 03:54 PM on Friday, May 23, 2025, and your container ship is docked at Da Nang Port. The cell guide system is damaged, risking cargo misalignment and operational delays. Vietnam ShipRepair offers expert Cell Guide Repair and Steel Works, providing reliable solutions at Da Nang Port and across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. Our services ensure your vessel remains efficient and compliant with global standards.

Vietnam ShipRepair technician inspecting a damaged cell guide at Da Nang Port.

Vietnam ShipRepair technician inspecting a damaged cell guide at Da Nang Port.

The Critical Importance of Cell Guide Repair for Container Ships

Cell guides are vital for container ships, securing cargo within holds to prevent shifting during transit. At Da Nang Port, where high cargo volumes demand precision, damaged guides can lead to container damage, safety hazards, and non-compliance with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards. Timely Cell Guide Repair and Steel Works are essential to maintain structural integrity, protect cargo, and ensure smooth operations.

Benefits of Timely Cell Guide Repair and Steel Works

Investing in Steel Works delivers significant operational and economic advantages:

-

Enhanced Operational Efficiency: Repaired guides ensure secure cargo handling, speeding up loading at Nghi Son or Vung Tau.

-

Reduced Downtime: Quick repairs prevent delays, keeping schedules on track.

-

Cost Savings: Timely maintenance avoids extensive repairs or replacements, lowering expenses.

-

Regulatory Compliance: Adherence to IMO and IACS standards ensures your vessel passes inspections.

Vietnam ShipRepair’s expertise maximizes productivity, savings, and compliance. Learn more about IMO standards here.

Vietnam ShipRepair team performing Steel Works on a cell guide at Da Nang port.

Vietnam ShipRepair team performing Steel Works on a cell guide at Da Nang port.

Our Cell Guide Repair and Steel Works Process

Vietnam ShipRepair follows a rigorous process for Cell Guide Repair and Steel Works, ensuring quality and compliance:

-

Detailed Inspection: Technicians assess damage using advanced tools to identify structural issues.

-

Material Selection: We use high-strength steel designed for marine conditions.

-

Precision Repair: Engineers reinforce or replace guides, adhering to IMO and IACS standards.

-

Testing and Installation: Each guide is tested and reinstalled, ready for use at Da Nang Port.

This process guarantees reliable performance across Vietnam. Visit Vietnam ShipRepair Services for more details.

Why Vietnam ShipRepair is Your Trusted Partner

With over 20 years of experience, Vietnam ShipRepair leads in maritime solutions. We provide Steel Works at:

-

Da Nang Port

-

Nghi Son Port and Anchorage

-

Vung Tau Anchorage

-

Ho Chi Minh City Ports and Anchorage

Our workshops in Hai Phong and Ho Chi Minh City leverage cutting-edge technology, ensuring IMO and IACS compliance. Ship operators trust our reliability and nationwide coverage for peace of mind.

A repaired cell guide securing containers at Da Nang port.

A repaired cell guide securing containers at Da Nang port.

Secure Your Voyage with Vietnam ShipRepair

Don’t let damaged cell guides disrupt your operations. Choose Vietnam ShipRepair for expert Cell Guide Repair and Steel Works at Da Nang Port and beyond.

Choose Vietnam Shiprepair for efficient, reliable Cell Guide Repair and Steel Works that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

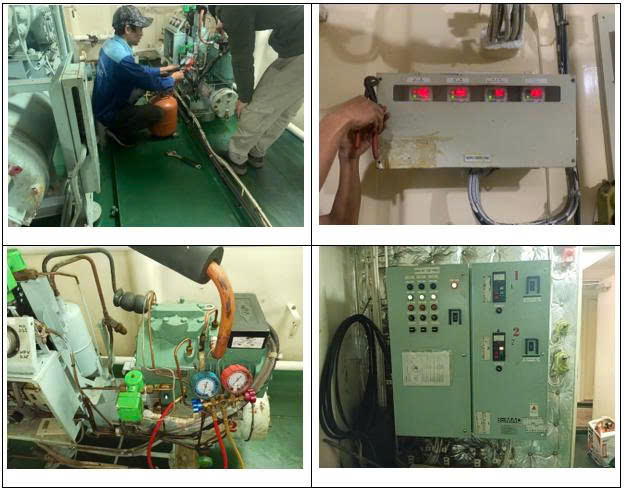

Refrigeration Repair for Provision Storage at Van Phong Anchorage

Refrigeration Repair for Provision Storage at Van Phong Anchorage

It’s 03:40 AM on Friday, May 09, 2025, and your vessel is anchored at Van Phong Anchorage. The refrigeration unit for provision storage fails, threatening food safety and crew well-being. Vietnam ShipRepair delivers expert Refrigeration Repair and Provision Storage maintenance, serving Van Phong Anchorage and ports across Vietnam, including Da Nang, Nghi Son, Vung Tau, and Ho Chi Minh City. Our services ensure your crew stays supported and your vessel remains compliant.

Technician checking refrigeration unit for provision storage.

Technician checking refrigeration unit for provision storage.

The Crucial Role of Provision Storage on Bulk Carriers

Provision storage, supported by reliable refrigeration, is vital for bulk carriers, preserving food and supplies for long voyages. At Van Phong Anchorage, where vessels may remain for extended periods, a functioning refrigeration system prevents spoilage, ensuring crew health and morale. A failing unit can lead to food loss, health risks, and non-compliance with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards. Timely Refrigeration Repair and Provision Storage maintenance are essential to uphold operational integrity.

Benefits of Timely Refrigeration Repair and Maintenance

Investing in Refrigeration Repair and Provision Storage maintenance offers significant operational and economic benefits:

-

Enhanced Crew Welfare: Repaired units maintain food freshness, boosting crew health and productivity at Da Nang or Vung Tau.

-

Reduced Downtime: Quick repairs prevent operational delays, keeping schedules on track.

-

Cost Savings: Regular maintenance avoids major replacements, lowering long-term expenses.

-

Regulatory Compliance: Adherence to IMO and IACS standards ensures inspection success.

Vietnam ShipRepair’s expertise maximizes efficiency, savings, and compliance. Explore IMO guidelines here.

Vietnam ShipRepair team performing Refrigeration Repair at Ho Chi Minh City port.

Vietnam ShipRepair team performing Refrigeration Repair at Ho Chi Minh City port.

Our Refrigeration Repair and Maintenance Process

Vietnam ShipRepair follows a meticulous process for Refrigeration Repair and Provision Storage maintenance, ensuring quality and compliance:

-

Thorough Inspection: Technicians assess the refrigeration system for faults using advanced diagnostics.

-

Component Replacement: We use high-quality parts designed for marine environments.

-

Expert Repair: Engineers restore or maintain units, adhering to IMO and IACS standards.

-

Testing and Optimization: Each system is tested and recommissioned, ready for use at Van Phong Anchorage.

This process guarantees reliable performance across Vietnam. Visit Vietnam ShipRepair Services for more details.

Why Vietnam ShipRepair is Your Trusted Partner

With over 20 years of experience, Vietnam ShipRepair excels in maritime solutions.

Choose Vietnam Shiprepair for efficient, reliable Refrigeration Repair and Provision Storage that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.