- by Vietnam Ship Repair

- 0

Turbocharger Overhauling at Cai Mep Port

Turbocharger Overhauling at Cai Mep Port – Expert Marine Services by VietNam Shiprepair

Is your vessel’s turbocharger due for overhauling at Cai Mep Port? VietNam Shiprepair Co. provides professional Turbocharger Overhauling and Marine Services, ensuring maximum engine efficiency. On December 29, 2025, we successfully completed a full Turbocharger Overhauling for a Panamax bulk carrier at Cai Mep Port, restoring optimal performance without delaying the vessel’s schedule. Our Marine Services extend to all ports and anchorages across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. All work complies with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust VietNam Shiprepair!

VTR304 turbocharger before overhauling at Cai Mep Port.

VTR304 turbocharger before overhauling at Cai Mep Port.

Importance of Turbocharger Overhauling on Panamax Vessels

The turbocharger is the heart of the main engine on Panamax bulk carriers, delivering the necessary air for combustion. When components like bearings, nozzle rings, or the rotor become worn, efficiency drops, fuel consumption rises, and engine output decreases. Regular Turbocharger Overhauling by VietNam Shiprepair restores performance, reduces fuel costs, and ensures IACS/IMO compliance.

Steps for VTR304 Turbocharger Overhauling

VietNam Shiprepair recently performed a complete Turbocharger Overhauling on a VTR304 unit at Cai Mep Port. Here are the key steps:

-

Initial Inspection: Disassemble the turbocharger and inspect rotor, turbine blades, nozzle ring, and bearings for wear, carbon build-up, and damage.

-

Cleaning: Thoroughly clean all parts, including turbine washing and compressor side degreasing.

-

Component Replacement: Replace worn bearings, seals, and O-rings with genuine or OEM parts.

-

Rotor Balancing: Dynamically balance the rotor to eliminate vibration and extend bearing life.

-

Nozzle Ring & Diffuser Repair: Polish or replace nozzle ring and diffuser to restore airflow efficiency.

-

Reassembly and Testing: Reassemble with precise clearances, lubricate with approved oil, and bench test for leaks and rotation.

-

Final Verification: Install on engine, run under load, and verify performance parameters.

This process ensures the turbocharger operates at peak efficiency.

Importance of Minimizing Downtime During Overhauling

Turbocharger overhauling must be completed quickly at Cai Mep Port to avoid engine downtime and schedule delays. VietNam Shiprepair’s Marine Services prioritize rapid execution, completing jobs efficiently with workshop support, ensuring IACS/IMO compliance.

VietNam Shiprepair’s Compliance with Turbocharger Overhauling

A trusted provider must follow strict standards. VietNam Shiprepair uses genuine parts and NK-certified technicians. The overhauling process is supervised by NK, guaranteeing adherence to IMO and IACS guidelines for reliable turbocharger performance.

VietNam Shiprepair’s Nationwide Marine Services Network

Provides Marine Services, including Turbocharger Overhauling, across Vietnam:

-

Cai Mep Port: Ideal for efficient overhauls, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for VietNam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at VietNam Shiprepair Services.

Technician inspection/cleaning rotor during VTR304 turbocharger overhauling at Cai Mep Port.

Technician inspection/cleaning rotor during VTR304 turbocharger overhauling at Cai Mep Port.

Benefits of Choosing VietNam Shiprepair for Turbocharger Overhauling

Choosing VietNam Shiprepair for Turbocharger Services offers peace of mind. Our Marine Services save time, maintaining schedules at Cai Mep Port. Cost-effective repairs with genuine parts reduce fuel consumption and extend engine life. Our NK-certified experts enhance reliability, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Overhauled VTR304 turbocharger reinstalled and operational at Vung Tau.

Overhauled VTR304 turbocharger reinstalled and operational at Vung Tau.

VietNam Shiprepair’s Commitment to Excellence

Our overhauling process guarantees quality. We inspect thoroughly, replace critical components, balance rotors, and test rigorously. We uphold IACS and IMO standards with NK supervision throughout. Choose VietNam Shiprepair for reliable Marine Services.

Contact VietNam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Governor Overhauling at Cai Mep Port

Governor Overhauling at Cai Mep Port – Expert Marine Services by Vietnam Shiprepair

Is your vessel’s mechanical governor causing unstable voltage in the 440V/60Hz electrical system at Cai Mep Port? Vietnam Shiprepair Co. provides expert Governor Overhauling and Marine Services, ensuring reliable power generation. On December 24, 2025, we successfully overhauled a mechanical governor for a bulk carrier at Cai Mep Port, restoring stable engine speed and voltage without disrupting the vessel’s schedule. Our Marine Services extend to all ports and anchorages across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. All work complies with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust Vietnam Shiprepair for dependable Marine Services!

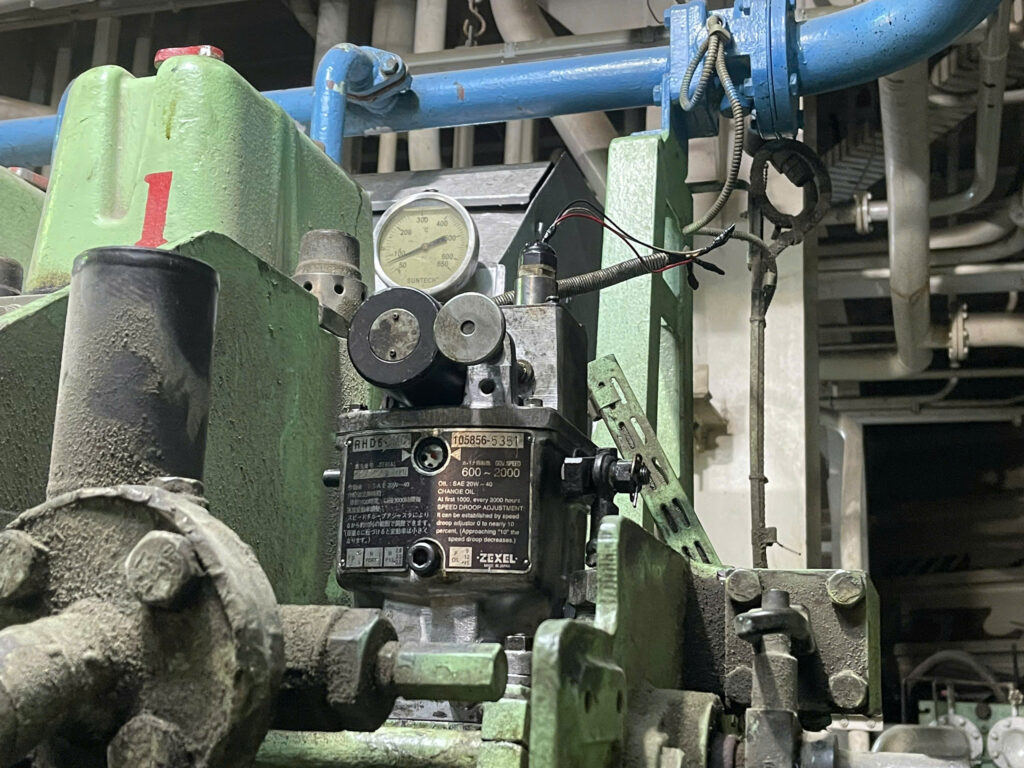

Mechanical governor showing wear before overhauling at Cai Mep Port.

Mechanical governor showing wear before overhauling at Cai Mep Port.

Importance of Governor Overhauling for Ship Electrical Stability

The mechanical governor is vital for maintaining stable engine speed and 440V/60Hz voltage on bulk carriers at Cai Mep Port. When worn or miscalibrated, it causes voltage fluctuations, risking equipment damage and operational delays. Vietnam Shiprepair’s Governor Overhauling restores precise control, ensuring IACS/IMO compliance and reliable power supply.

Steps for Mechanical Governor Overhauling

Vietnam Shiprepair recently overhauled a mechanical governor at Cai Mep Port. Here are the key steps:

-

Initial Inspection: Disassemble the governor to check flyweights, springs, linkages, and oil condition for wear or sticking.

-

Component Replacement: Replace worn parts such as O-rings, gaskets, bearings, and springs with genuine or OEM equivalents.

-

Cleaning and Reassembly: Clean all parts thoroughly, lubricate with approved oil, and reassemble with precise calibration of droop and isochronous settings.

-

Testing and Calibration: Bench test for speed stability, then run on the engine to adjust for 440V/60Hz under various loads.

-

Final Verification: Confirm voltage stability and load-sharing with other generators, supervised by NK.

This process ensures smooth operation and prevents voltage instability.

Importance of Minimizing Downtime During Overhauling

Overhauling a governor quickly is critical at Cai Mep Port to avoid power disruptions. Delays can affect navigation, cargo handling, and safety systems. Vietnam Shiprepair’s Marine Services prioritize rapid execution, completing overhauls efficiently while maintaining IACS/IMO compliance.

Vietnam Shiprepair’s Compliance with Governor Overhauling

A trusted provider must follow strict standards. Vietnam Shiprepair uses certified parts and NK-supervised technicians. The overhauling process ensures adherence to IMO and IACS guidelines for stable electrical systems.

Vietnam Shiprepair’s Nationwide Marine Services Network

Provides Marine Services, including Governor Overhauling, across Vietnam:

-

Cai Mep Port: Ideal for efficient overhauls, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

Technician calibrating mechanical governor during overhauling at Cai Mep Port.

Technician calibrating mechanical governor during overhauling at Cai Mep Port.

Benefits of Choosing Vietnam Shiprepair for Governor Overhauling

Choosing Vietnam Shiprepair for Governor Overhauling offers peace of mind. Our Marine Services save time, maintaining schedules at Cai Mep Port. Cost-effective repairs restore voltage stability, reducing risks to electrical systems. Our NK-certified experts enhance reliability, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Overhauled mechanical governor in stable operation at Vung Tau.

Overhauled mechanical governor in stable operation at Vung Tau.

Our overhauling process guarantees quality. We inspect thoroughly, replace critical components, calibrate precisely, and test under load. We uphold IACS and IMO standards with NK supervision throughout. Choose Vietnam Shiprepair for reliable Marine Services.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Davit Arms Repair at Quy Nhon Port

Davit Arms Repair at Quy Nhon Port – Expert Marine Services by VietNam Shiprepair

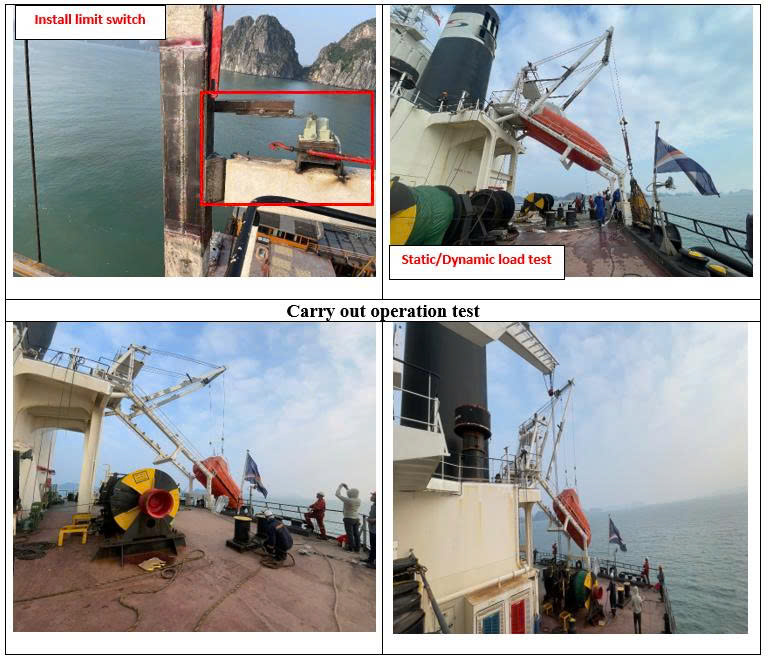

Is your vessel’s davit arms deformed at Quy Nhon Port? VietNam Shiprepair Co. offers professional Davit Arms Repair and Marine Services, ensuring safe lifeboat operations. On December 18, 2025, we successfully repaired deformed davit arms on a vessel at Quy Nhon Port, straightening, reinforcing, and adding limit stops without delaying the schedule. Our Marine Services extend to all ports and anchorages across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. All repairs comply with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust VietNam Shiprepair!

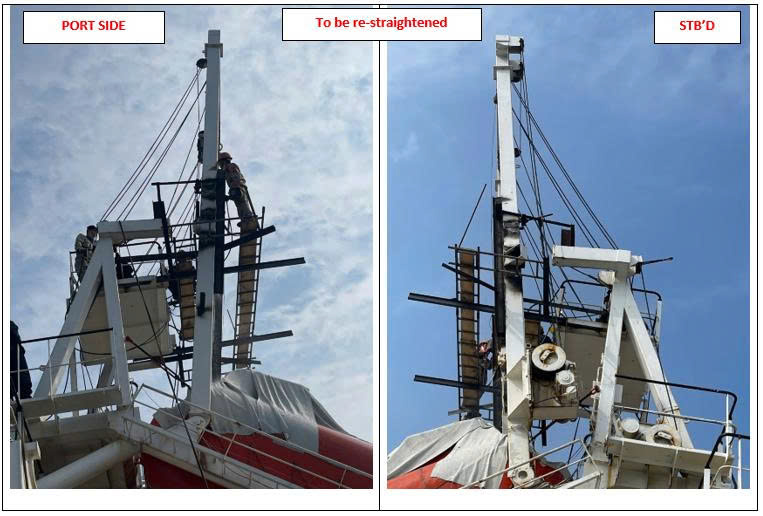

Deformed davit arms at Quy Nhon Port before repair.

Deformed davit arms at Quy Nhon Port before repair.

Importance of Davit Arms for Lifeboat Systems

Davit arms are critical for safe lifeboat launching and recovery at Quy Nhon Port. When deformed due to over-recovery or impact, they pose serious safety risks and may violate IACS/IMO standards. VietNam Shiprepair’s Davit Arms Repair restores structural integrity, ensuring compliance and crew safety.

Steps for Davit Arms Repair

VietNam Shiprepair recently repaired deformed davit arms at Quy Nhon Port. Here are the key steps:

-

Erect Staging Safely: Build scaffolding to access the high-positioned davit arms securely.

-

Straighten the Arms: Use hydraulic pressing to realign the arms to original design specifications.

-

Fix and Reinforce: Secure the structure and add reinforcements to prevent future deformation.

-

Cut Out Damaged Section: Remove the deformed part with precision cutting.

-

Replace with New Plate: Install new 8mm AH36 steel plate for durability.

-

Weld with Reinforcement: Perform certified welding with additional strengthening.

-

NDT Inspection: Conduct non-destructive testing to verify weld quality.

-

Painting: Apply anti-corrosion coating after welding.

-

Load Test: Perform a 12.1-ton load test.

-

Operational Test: Verify full function.

-

Install Limit Stop: Add a limit device to ensure safe operation and prevent over-recovery.

This process ensures reliability and safety.

Importance of Minimizing Downtime During Repair

Repairing davit arms quickly is essential at Quy Nhon Port to avoid lifeboat system delays. Delays can compromise crew safety and schedules. VietNam Shiprepair’s Marine Services prioritize rapid, safe execution, completing repairs efficiently while maintaining IACS/IMO compliance.

VietNam Shiprepair’s Compliance with Davit Arms Repair

A trusted provider must follow strict standards. VietNam Shiprepair uses AH36 steel and NK-certified welders. The process is supervised by NK, ensuring adherence to IMO and IACS guidelines for safe davit arms.

VietNam Shiprepair’s Nationwide Marine Services Network

Provides Marine Services, including Davit Arms Repair, across Vietnam:

-

Quy Nhon Port: Ideal for efficient repairs, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for VietNam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at VietNam Shiprepair Services.

Team welding new AH36 plate on davit arms at Quy Nhon Port.

Team welding new AH36 plate on davit arms at Quy Nhon Port.

Benefits of Choosing VietNam Shiprepair for Davit Arms Repair

Choosing VietNam Shiprepair for Davit Arms Repair offers peace of mind. Our Marine Services save time, maintaining schedules at Quy Nhon Port. Using 8mm AH36 steel and adding limit stops reduce future risks. Our NK-certified experts enhance safety and reputation, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Repaired davit arms after load test Quy Nhon Port.

Repaired davit arms after load test Quy Nhon Port.

VietNam Shiprepair’s Commitment to Excellence

Our repair process guarantees quality. We erect safe staging, straighten and reinforce, replace with AH36 steel, weld precisely, NDT inspect, paint, load test (12.1 tons), and install limit stops. We uphold IACS and IMO standards with NK supervision. Choose VietNam Shiprepair for reliable Marine Services.

Contact VietNam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Hydraulic Pump Overhaul at Cai Mep Port

Hydraulic Pump Overhaul at Cai Mep Port – Professional Marine Services by VietNam Shiprepair

Is your MacGregor hydraulic pump showing signs of wear on your bulk carrier at Cai Mep Port? VietNam Shiprepair Co. provides expert Hydraulic Pump Overhaul and Marine Services, ensuring reliable hatch cover operation. On December 16, 2025, we successfully overhauled a MacGregor hydraulic pump, replacing O-rings, bearings, and seals while grinding the swash plate, with zero delay to the vessel’s schedule. Our Marine Services extend to all ports and anchorages across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. All work complies with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust VietNam Shiprepair for professional Marine Services!

MacGregor hydraulic pump showing worn swash plate before overhaul at Cai Mep Port. Worn swash plate on MacGregor hydraulic pump before overhaul.

MacGregor hydraulic pump showing worn swash plate before overhaul at Cai Mep Port. Worn swash plate on MacGregor hydraulic pump before overhaul.

Importance of Hydraulic Pump Overhaul for Hatch Covers

The hydraulic pump is the core component of hatch cover systems on bulk carriers at Cai Mep Port. When O-rings leak, bearings wear, or the swash plate gets scratched, it reduces pressure and risks hatch cover failure. Regular Hydraulic Pump Services by VietNam Shiprepair prevents downtime, ensures IACS/IMO compliance, and extends equipment life.

Steps for MacGregor Hydraulic Pump Overhaul

VietNam Shiprepair recently overhauled a MacGregor hydraulic pump at Cai Mep Port. Here are the key steps:

-

Disassembly and Inspection: Remove the pump from the power unit, disassemble, and inspect for wear on O-rings, bearings, and swash plate scratches.

-

Component Replacement: Install new O-rings, bearings, and seals using genuine MacGregor parts for perfect fit and durability.

-

Swash Plate Grinding: Carefully grind the scratched swash plate surface to restore flatness and smoothness, ensuring optimal piston movement.

-

Reassembly and Testing: Reassemble with precise torque settings, fill with fresh ISO VG46 oil, and pressure test (180-250 bar) for leak-free operation.

This process restores full performance while maintaining structural integrity.

Importance of Minimizing Downtime with Marine Services

Overhauling a hydraulic pump quickly is essential at Cai Mep Port to avoid hatch cover delays and cargo schedule disruptions. VietNam Shiprepair’s Marine Services prioritize fast turnaround, completing jobs efficiently with workshop support, ensuring IACS/IMO compliance and client satisfaction.

VietNam Shiprepair’s Compliance with Hydraulic Pump Overhaul

A trusted provider must follow strict procedures. VietNam Shiprepair uses genuine parts and NK-certified technicians. The overhaul process is supervised by NK, guaranteeing adherence to IMO and IACS guidelines for reliable hatch cover operation.

VietNam Shiprepair’s Nationwide Marine Services Network

Provides Marine Services, including Hydraulic Pump Services, across Vietnam:

-

Cai Mep Port: Ideal for efficient repairs, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for VietNam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at VietNam Shiprepair Services.

Team grinding the swash plate during MacGregor hydraulic pump overhaul at Cai Mep Port. Team grinding swash plate during hydraulic pump overhaul.

Team grinding the swash plate during MacGregor hydraulic pump overhaul at Cai Mep Port. Team grinding swash plate during hydraulic pump overhaul.

Benefits of Choosing VietNam Shiprepair for Hydraulic Pump Overhaul

Choosing VietNam Shiprepair for Hydraulic Pump Overhaul offers peace of mind. Our Marine Services save time, maintaining hatch cover schedules at Cai Mep Port. Cost-effective replacement of O-rings, bearings, and seals reduces expenses compared to full unit replacement. Our NK-certified experts enhance safety and reliability, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Reassembled MacGregor hydraulic pump after overhaul in stable operation at Vung Tau. Reassembled hydraulic pump after overhaul in stable operation.

Reassembled MacGregor hydraulic pump after overhaul in stable operation at Vung Tau. Reassembled hydraulic pump after overhaul in stable operation.

VietNam Shiprepair’s Commitment to Excellence

Our overhaul process guarantees quality. We inspect thoroughly, replace critical components, grind the swash plate with precision, and test rigorously. We uphold IACS and IMO standards with NK supervision throughout. Choose VietNam Shiprepair for reliable Marine Services.

Contact VietNam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Clamshell Grab Hydraulic Pump Replacement

Clamshell Grab Hydraulic Pump Replacement – Professional Marine Services by VietNam Shiprepair

Is your radio-remote or hydraulic Clamshell Grab suffering from a failed hydraulic pump? VietNam Shiprepair offers fast, expert Marine services for grab repairs anywhere in Vietnam and Southeast Asia. On October 21, 2025, our riding team successfully replaced the complete hydraulic pump on a 14 m³ clamshell grab at Cai Mep anchorage in just 8 hours – zero delay to the vessel’s schedule. We provide 24/7 Marine services at all major ports and anchorages including Cai Mep, Vung Tau, Dung Quat, Nghi Son, and Singapore OPL. All repairs are performed to IACS and class society standards (DNV, NK, ABS, LR). Trust VietNam Shiprepair – your reliable partner for Clamshell Grab repairs.

Failed hydraulic pump removed from 14 m³ clamshell grab at Cai Mep anchorage

Failed hydraulic pump removed from 14 m³ clamshell grab at Cai Mep anchorage

Why Hydraulic Pump Failure is Critical for Clamshell Grabs

The hydraulic pump is the heart of every modern Clamshell Grab. When it fails, the grab cannot close properly, dramatically reducing discharging rates and causing expensive delays. Fast, professional Marine services are essential to get the grab back into full operation. VietNam Shiprepair’s riding teams carry stock pumps (Parker, Rexroth, Kawasaki, and OEM Chinese) and can mobilise within hours.

Step-by-Step Hydraulic Pump Replacement Process

Our experienced technicians follow this proven procedure:

-

Safe positioning of the grab on deck with wooden supports

-

Full depressurisation and isolation of the hydraulic system

-

Removal of high-pressure hoses and mounting bolts

-

Careful extraction of the old pump (120–180 kg) using a deck crane

-

Installation of the new, class-approved hydraulic pump with correct torque settings

-

Replacement of all seals and O-rings

-

Refilling with fresh ISO VG46 hydraulic oil and complete air bleeding

-

Pressure testing (180–220 bar working, 280 bar max)

-

No-load and full-load function tests (1.5 × SWL)

-

Final handover with class surveyor attendance (DNV/NK/ABS) if required

The entire job is normally completed within 6–10 hours by a 4–5 man team.

New hydraulic pump successfully installed and tested on 14 m³ clamshell grab.

New hydraulic pump successfully installed and tested on 14 m³ clamshell grab.

VietNam Shiprepair – Your 24/7 Grab Repair Specialist

-

Stock of most common hydraulic pumps for 6–36 m³ grabs

-

Riding teams available Vietnam-wide and Singapore OPL

-

Original and OEM spare parts with class certificates

-

Full documentation and class attendance arranged

-

Competitive fixed prices – no hidden costs

Whether you operate SMAG, NMK, Peiner, IHI, Fukushima or Chinese-built grabs, we have the expertise and parts ready.

Contact VietNam Shiprepair Now

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Mobile / WhatsApp / WeChat: +84 869 677 769

-

Email: contact@vietnamshiprepair.net

-

Website: https://vietnamshiprepair.net

-

24-hour emergency grab repair service

- by Vietnam Ship Repair

- 0

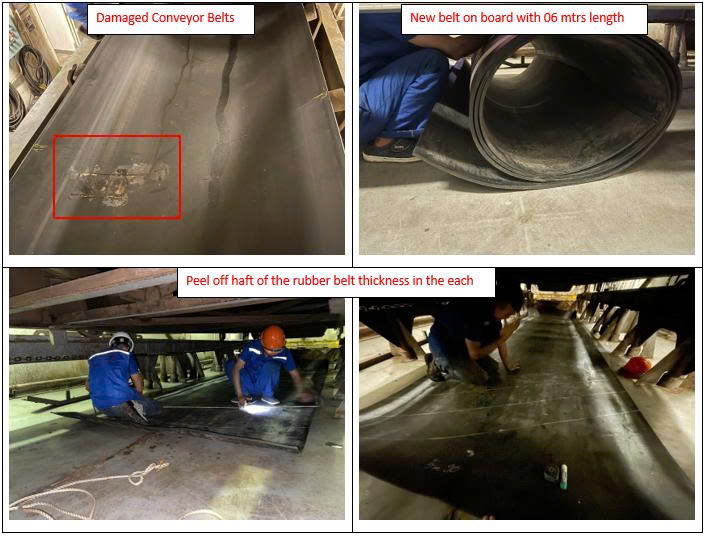

Rubber Conveyor Belt Replacement at Chan May Port

Cold Bonding Rubber Conveyor Belt Replacement at Chan May Port – Vietnam Shiprepair

When uptime and safety matter most, Vietnam Shiprepair delivers.

On November 13, 2025, our certified technicians successfully completed a Cold Bonding Rubber Conveyor Belt Replacement for a wood chip carrier at Chan May Port, ensuring seamless cargo handling without disrupting the vessel’s schedule.

We provide professional Marine Conveyor Belt Repair and onboard belt maintenance for wood chip carriers at all major ports and anchorages across Vietnam, including Nghi Son, Vung Tau, Ho Chi Minh City, and Chan May. All work strictly follows IACS and IMO standards for marine safety and compliance.

Why Cold Bonding Rubber Conveyor Belts Matter

Why Cold Bonding Rubber Conveyor Belts Matter

Rubber conveyor belts are essential for wood chip carriers, enabling continuous, efficient, and safe cargo transfer.

A worn or damaged conveyor belt can cause:

-

Slower cargo movement and potential spills

-

Unsafe conditions for personnel

-

Delays at port and non-compliance with IACS/IMO regulations

With Cold Bonding, Vietnam Shiprepair restores the belt’s strength and reliability without using heat, making it ideal for confined spaces like forepeak tanks or covered deck conveyors.

Step-by-Step: Cold Bonding Rubber Conveyor Belt Replacement at Chan May Port

Material Selection

We use IMO- and IACS-approved rubber belts, reinforced with EP fabric or steel cord. The adhesives are marine-grade cold bonding compounds, providing high tensile strength and long-term wear resistance.

Safe Removal of Worn Belt

Technicians lock out and tag out all drive systems. The old belt is cut into sections, removed safely, and disposed of properly.

Cold Bonding Installation

-

Prepare belt ends: clean, buff, and degrease

-

Apply adhesive layers: 2–3 coats, allowing curing between layers

-

Press belt ends together using mechanical rollers or clamps for uniform adhesion and precise alignment

-

Curing period: adhesive sets at ambient temperature, typically 18-20 hours

Cold bonding avoids heat, making it safe for confined or sensitive areas while achieving a seamless, strong joint.

Testing & Commissioning

After curing, belts are tested:

-

No-load run to verify alignment

-

Load simulation to confirm tension and smooth cargo flow

-

Final inspection ensures tracking and belt integrity

The conveyor system is returned to full operational service only after passing all checks.

Minimizing Downtime – Maximizing Efficiency

Minimizing Downtime – Maximizing Efficiency

Every hour in port counts.

Our mobile repair teams replace belts quickly without delaying cargo operations. Cold Bonding allows work in tight spaces, reducing risk and ensuring uninterrupted vessel turnaround.

Certified Quality – IACS & IMO Compliance

All Vietnam Shiprepair technicians are IACS-certified.

Every job includes:

-

Belt specification and batch documentation

-

Cold bonding log (adhesive type, layer count, curing time)

-

Inspection checklist and compliance verification

This guarantees a traceable, class-approved repair process every time.

Why Choose Vietnam Shiprepair

-

20+ years of experience in marine repair and bulk cargo systems

-

IACS/IMO certified technicians

-

Cold bonding expertise for safe and durable splicing

-

Fast, mobile response across all Vietnamese ports

-

Cost-effective solutions minimizing downtime

With Vietnam Shiprepair, you get reliable, long-term solutions for Marine Conveyor Belt Maintenance.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Head Office: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam

Mobile/WhatsApp/WeChat: +84 869 677 769

Email: contact@vietnamshiprepair.net

Website: https://vietnamshiprepair.net

- by Vietnam Ship Repair

- 0

Accommodation Ladder Repair at Cai Mep Port

Accommodation Ladder Repair at Cai Mep Port – Expert Marine Services by VietNam Shiprepair

Is your vessel’s accommodation ladder damaged at Cai Mep Port? VietNam Shiprepair Co. provides professional Accommodation Ladder repair and Marine services, ensuring safe access for crew. On October 21, 2025, at 04:55 PM +07, we successfully repaired a deformed turntable on an accommodation ladder at Cai Mep, using hydraulic pressing with heat without delaying the ship’s schedule. Our Marine services extend to all ports and anchorages across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. All repairs comply with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Trust VietNam Shiprepair for dependable Marine services!

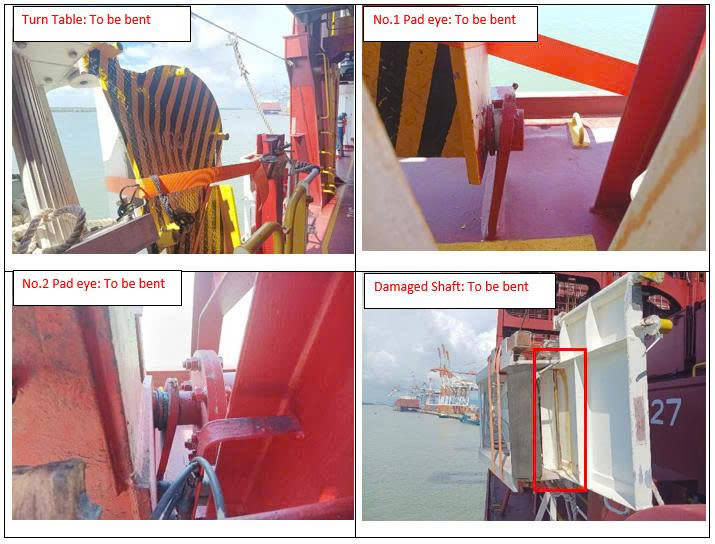

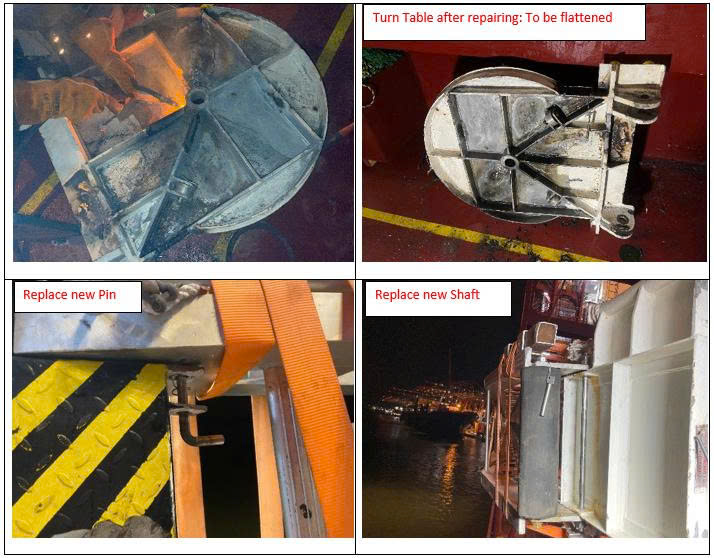

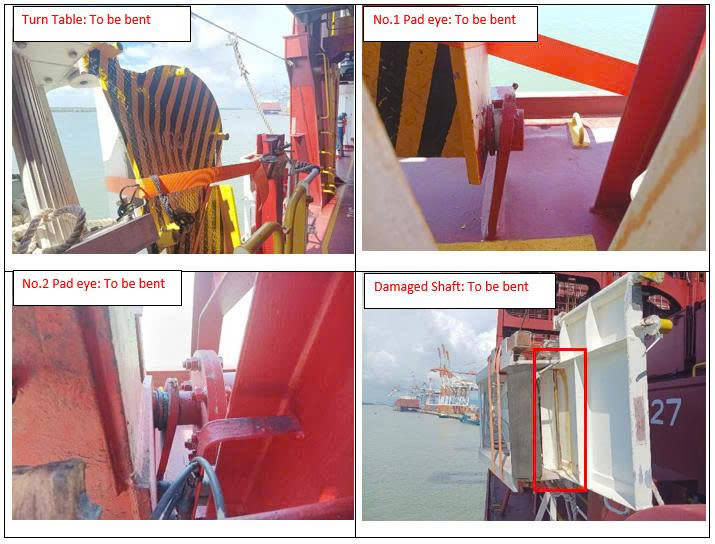

Deformed turntable on accommodation ladder at Cai Mep Port before repair.

Deformed turntable on accommodation ladder at Cai Mep Port before repair.

Importance of Accommodation Ladder and Turntable on Ships

The Accommodation Ladder is crucial for safe crew boarding and disembarking at Cai Mep Port. The turntable, a key component, allows rotation for alignment with docks or tenders. When deformed due to impact, it poses safety risks and may violate IACS/IMO standards. VietNam Shiprepair’s Marine services ensure quick restoration, maintaining vessel operations and compliance.

Basic Steps for Accommodation Ladder Turntable Repair

VietNam Shiprepair recently repaired a deformed turntable on an Accommodation Ladder at Cai Mep Port. Here are the key steps:

-

Secure Portside Accommodation Gangway at the Rest Station: Stabilize the ladder in its rest position to prevent movement during repair.

-

Erect Staging Properly and Safely: Set up scaffolding with safety rails and harnesses to access the high-positioned turntable securely.

-

Dismount Turntable, Put on Deck, and Flatten by Hydraulic Pressure Under the Influence of Heat: Carefully remove the turntable, place it on deck, and use hydraulic press with controlled heat to straighten the deformation.

-

Remove Damaged Parts and Replace New Ones: Cut out damaged sections and install new components made from mid steel for durability.

-

Mount Turntable in Order and Test Operation: Reassemble the turntable and perform functional tests to ensure smooth rotation.

-

Load Test with Witness of DNV Class Surveyor After Repair: Conduct load tests under DNV supervision to verify safety and compliance.

This process ensured efficient repair, but timely execution is essential to avoid delays.

Importance of Minimizing Downtime During Repair

Repairing an Accommodation Ladder quickly is vital at Cai Mep Port to avoid operational disruptions. Delays can compromise crew safety and schedules. VietNam Shiprepair’s Marine services prioritize rapid, safe execution, completing repairs efficiently while maintaining IACS/IMO compliance.

VietNam Shiprepair’s Compliance with Accommodation Ladder Repair

A reputable provider must follow strict protocols. VietNam Shiprepair uses advanced techniques and DNV-certified technicians. The process is supervised by DNV, ensuring adherence to IMO and IACS guidelines for safe, durable Accommodation Ladder repairs.

VietNam Shiprepair’s Nationwide Marine Services Network

Provides Marine services, including Accommodation Ladder repair, across Vietnam:

-

Cai Mep Port: Ideal for efficient repairs, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for VietNam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at VietNam Shiprepair Services.

Team dismounting and flattening the turntable at Cai Mep Port.

Team dismounting and flattening the turntable at Cai Mep Port.

Benefits of Choosing VietNam Shiprepair for Accommodation Ladder Repair

Choosing VietNam Shiprepair for Marine services offers peace of mind. Our Marine services save time, maintaining schedules at Cai Mep Port. Cost-effective solutions reduce expenses compared to full replacements. Our DNV-certified experts enhance vessel safety and reputation, backed by over 20 years of experience and IACS/IMO compliance with detailed reports.

Repaired accommodation ladder in stable operation at Vung Tau.

Repaired accommodation ladder in stable operation at Vung Tau.

VietNam Shiprepair’s Commitment to Excellence

Our repair process guarantees quality. We secure the ladder, erect safe staging, dismount and flatten the turntable, replace damaged parts, reassemble, and test thoroughly. We uphold IACS and IMO standards with DNV supervision. Choose VietNam Shiprepair for reliable Marine services.

Contact VietNam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Steel Works at Cai Lan Port

Steel Works at Cai Lan Port – Expert Marine Services by Vietnam Shiprepair

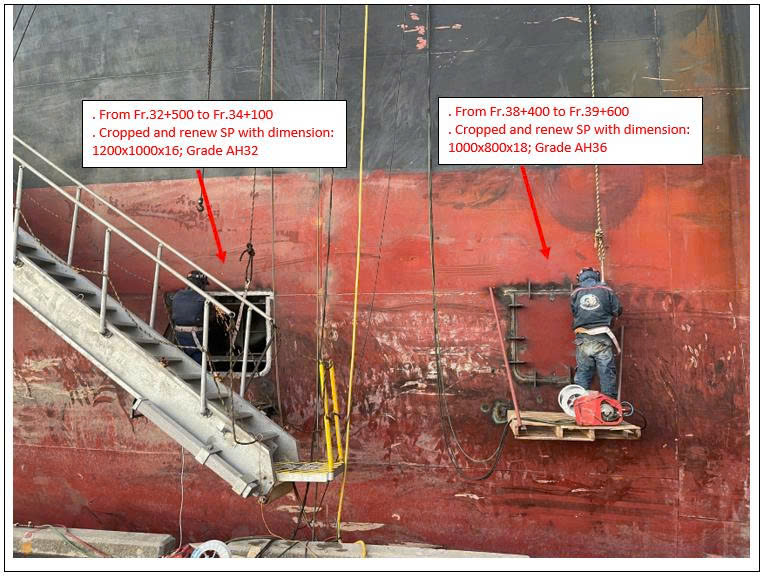

Are you searching for top-tier Marine Services to handle steel works for ship repairs at Cai Lan Port, ensuring structural integrity and minimal downtime? Vietnam Shiprepair Co. delivers specialized Ship Repair solutions, including advanced steel works, tailored to meet the demands of vessels facing collision damage. As of September, 2025, we successfully completed steel works on a bulk carrier’s deformed side shell at Cai Lan Port, adhering to International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards. Our Marine Services extend across Vietnamese ports like Nghi Son, Vung Tau, and Ho Chi Minh City. Trust our Vietnam Workshop for precise, safe, and efficient repairs—learn more at IACS Standards.

Bulk carrier undergoing steel works repair on side shell at Cai Lan Port.

Bulk carrier undergoing steel works repair on side shell at Cai Lan Port.

Importance of Steel Works in Ship Repair for Bulk Carriers

Bulk carriers, vital for transporting coal and ore, often face structural challenges like deformed side shells due to collisions, as seen recently at Cai Lan Port. Steel works—involving cutting, welding, and reinforcing steel components—is essential to restore hull integrity, prevent water ingress, and ensure cargo safety. Poorly executed repairs can lead to cracks or buckling, compromising vessel stability. Vietnam Shiprepair’s Marine Services provide robust hot works solutions, ensuring compliance with IACS/IMO standards and safeguarding operations in demanding maritime environments.

Why Choose Professional Steel Works for Ship Repair?

Professional Marine Services address critical issues like deformation and weld failures, using high-strength steel (e.g., AH36) to withstand stress. Substandard repairs risk structural collapse, especially in collision-damaged areas. Our Vietnam Workshop employs certified welders and advanced techniques, meeting IACS UR S11 for steel integrity and IMO SOLAS Chapter II-1 for seaworthiness. Opting for Vietnam Shiprepair’s Marine Services ensures durable repairs, minimizing risks and downtime at Cai Lan Port.

Steps to Perform Steel Works for Ship Repair

Vietnam Shiprepair recently executed steel works on a bulk carrier’s side shell at Cai Lan Port, following strict IACS/IMO protocols. Here’s the process:

-

Initial Assessment and Planning

Our Vietnam Workshop team conducted a detailed inspection, using Ultrasonic Testing to assess deformation and cracks. A repair plan was approved by NKK, specifying AH36 steel replacement. -

Removal of Damaged Steel

Damaged sections were cut out with plasma torches, ensuring clean edges, followed by grit blasting to remove rust and prepare for new steel. -

Fabrication and Installation

New AH36 steel plates were fabricated and aligned in our Vietnam Workshop, secured with tack welds for precise fitting. -

Welding and Reinforcement

Certified welders performed fillet welding, reinforced with stiffeners, and conducted Non-Destructive Testing to verify integrity. -

Final Coating and Inspection

Applied anti-corrosion epoxy coatings and underwent watertightness tests, with NKK surveyor approving the repair for compliance.

Vietnam Workshop team conducting steel works on bulk carrier at Cai Lan Port.

Vietnam Workshop team conducting steel works on bulk carrier at Cai Lan Port.

Safety and Efficiency in Marine Services

Executing hot works at Cai Lan Port requires stringent safety measures, especially in confined tank areas. Vietnam Shiprepair’s Marine Services adhere to IMO safety guidelines, providing full PPE (harnesses, respirators) and continuous ventilation. Our Vietnam Workshop ensures rapid, safe repairs, minimizing disruption to vessel schedules.

Vietnam Shiprepair’s Nationwide Marine Services Network

Our Marine Services cover Vietnam’s key ports:

-

Cai Lan Port: Ideal for steel works and repairs, as demonstrated recently.

-

Nghi Son Anchorage: A hub for efficient Ship Repair solutions.

-

Nationwide Reach: Serving Vung Tau, Ho Chi Minh City, and beyond.

-

Mobile Operations: Our Vietnam Workshop brings expertise to your location.

-

Rapid Response: Quick deployment reduces downtime.

Explore our offerings at Vietnam Shiprepair Services.

Benefits of Choosing Vietnam Shiprepair for Steel Works

Partnering with Vietnam Shiprepair for Marine Services offers:

-

IACS/IMO-compliant steel works, ensuring hull strength and safety.

-

Efficient turnaround, critical for busy ports like Cai Lan Port.

-

Cost-effective solutions, preventing extensive damage.

-

Skilled Vietnam Workshop technicians with decades of experience.

-

Detailed reports, enhancing vessel reliability.

Bulk carrier after steel works, operating stably at Cai Lan Port.

Bulk carrier after steel works, operating stably at Cai Lan Port.

Vietnam Shiprepair’s Commitment to Excellence

Our Marine Services combine expert assessments, precision steel works, and strict IACS/IMO adherence. Supervised by classification societies, our Vietnam Workshop delivers outstanding results for complex repairs. Choose Vietnam Shiprepair for superior steel works at Cai Lan Port!

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

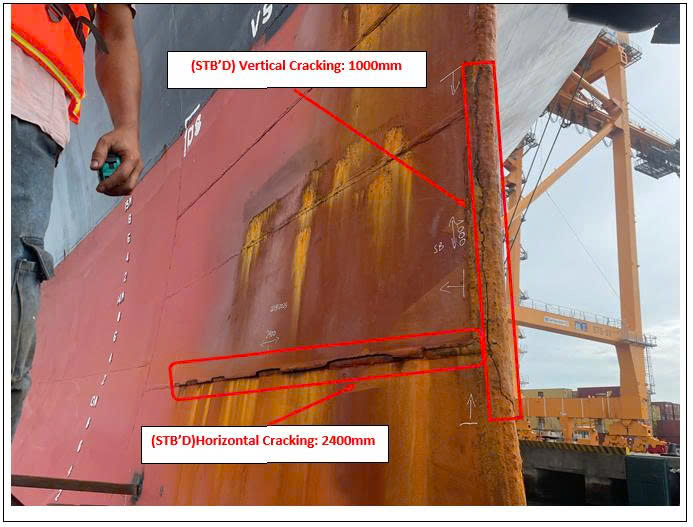

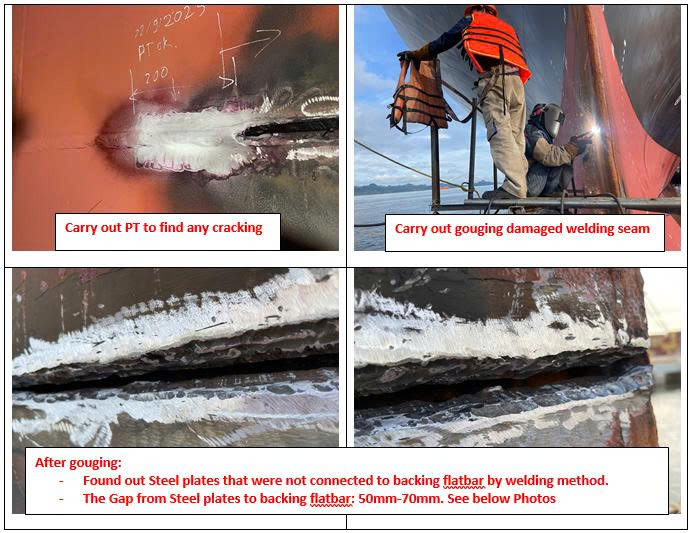

Structural Repair Due to Stress Damage – Marine Services

Structural Repair Due to Stress Damage at Cai Mep Port – Expert Marine Services by Vietnam Shiprepair

Are you facing structural damage on your container ship due to high stress loads, and need reliable Marine Services to restore integrity without extended downtime? Vietnam Shiprepair Co. specializes in Ship Repair solutions, addressing stress-induced failures in marine structures. In September 2025, we efficiently repaired structural damage caused by stress on a container ship at Cai Mep Port, ensuring compliance with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards. Our Marine Services extend to key Vietnamese ports like Nghi Son, Vung Tau, and Ho Chi Minh City. Trust our Vietnam Workshop for professional, safe, and time-efficient repairs—learn more at IACS Standards.

Container ship undergoing structural repair due to stress damage at Cai Mep Port.

Container ship undergoing structural repair due to stress damage at Cai Mep Port.

Importance of Structural Repair for Container Ships Due to Stress Damage

Container ships endure immense stress from cargo loads, wave impacts, and operational forces, leading to structural damage such as cracks, buckling, or deformations in hull components. At Cai Mep Port, a deep-water hub handling heavy container traffic, these issues are common due to high humidity, saline exposure, and frequent short-haul routes. Stress damage can compromise hull integrity, causing leaks, cargo loss, or even vessel instability. Timely structural repair is essential to prevent escalation, ensuring safety, compliance with IACS/IMO standards, and uninterrupted operations. Vietnam Shiprepair’s Marine Services focus on comprehensive assessments and reinforcements to mitigate these risks, extending vessel lifespan and reducing costly breakdowns.

Why Choose Professional Structural Repair for Stress Damage?

Professional structural repair addresses root causes like fatigue from repeated stress cycles or concentrations around welds and discontinuities, which can lead to failures if ignored. Inadequate reinforcements or poor welding exacerbate problems, resulting in buckling under compressive loads or cracks from tensile stress. Our Vietnam Workshop uses advanced techniques to restore strength, meeting IACS UR S11 for structural integrity. This ensures IMO SOLAS Chapter II-1 compliance, vital for seaworthiness in high-traffic areas like Cai Mep Port. Choosing expert Marine Services prevents minor issues from becoming major hazards, safeguarding cargo and crew.

Steps to Perform Structural Repair for Stress Damage on Container Ships

Vietnam Shiprepair recently handled structural repair for stress damage on a container ship at Cai Mep Port, adhering to rigorous IACS/IMO protocols. Here’s the general process:

-

Initial Assessment and Inspection

Conduct thorough visual inspections and Ultrasonic Testing to identify stress-induced cracks, deformations, or corrosion in affected areas. Our Vietnam Workshop team coordinates at Cai Mep Port’s Thi Vai or CMIT terminals, using tools like thickness gauges to evaluate material fatigue. -

Damage Removal and Preparation

Safely remove compromised sections using cutting torches or grinders, preparing surfaces for welding by cleaning rust and contaminants common in saline environments. -

Reinforcement and Welding

Fabricate reinforcements like stiffeners or brackets from high-strength steel in our Vietnam Workshop. Perform certified welding to restore integrity, addressing stress concentrations with proper joint designs. -

Application of Protective Coatings

Apply anti-corrosion epoxy or polyurethane coatings to protect repaired areas from further environmental stress, enhancing durability under wave loads. -

Final Testing and Certification

Conduct non-destructive tests (e.g., dye penetrant or ultrasonic) and load simulations to verify repairs. Generate reports for classification societies like NK or DNV, ensuring IACS/IMO compliance. The process minimizes downtime, allowing quick resumption at Cai Mep Port.

Vietnam Workshop team performing structural repair on container ship at Cai Mep Port.

Vietnam Workshop team performing structural repair on container ship at Cai Mep Port.

Safety and Professionalism in Marine Services

Repairing stress damage on container ships at Cai Mep Port involves risks from confined spaces and heavy loads. Vietnam Shiprepair’s Marine Services prioritize IMO safety guidelines, equipping teams with full PPE (harnesses, helmets, respirators) and implementing ventilation and dual supervision. We monitor coastal weather to avoid disruptions, ensuring efficient repairs that align with vessel schedules.

Vietnam Shiprepair’s Nationwide Marine Services Network

Our Marine Services cover Vietnam’s major maritime hubs:

-

Cai Mep Port: Ideal for container ship repairs, as in our recent stress damage project.

-

Nghi Son Anchorage: A hub for efficient Ship Repair solutions.

-

Nationwide Reach: Serving Vung Tau, Ho Chi Minh City, and all ports/anchorages.

-

Mobile Operations: Our Vietnam Workshop deploys tools directly to your vessel.

-

Rapid Response: Quick mobilization reduces downtime.

Explore our offerings at Vietnam Shiprepair Services.

Benefits of Choosing Vietnam Shiprepair for Structural Repair

Partnering with Vietnam Shiprepair for Marine Services provides:

-

IACS/IMO-compliant repairs, preventing stress-related failures and ensuring hull integrity.

-

Efficient turnaround, minimizing operational disruptions at Cai Mep Port.

-

Cost savings by addressing fatigue early, avoiding extensive overhauls.

-

Experienced Vietnam Workshop technicians with over 20 years in marine structural work.

-

Detailed reports, boosting vessel reliability and compliance.

Container ship after structural repair, operating stably at Cai Mep Port.

Container ship after structural repair, operating stably at Cai Mep Port.

Vietnam Shiprepair’s Commitment to Excellence

Our process combines skilled assessments, advanced welding, and strict IACS/IMO adherence to deliver robust repairs for stress damage. Supervised by classification societies, our Vietnam Workshop ensures flawless outcomes, satisfying demanding clients. Choose Vietnam Shiprepair for superior Marine Services at Cai Mep Port!

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

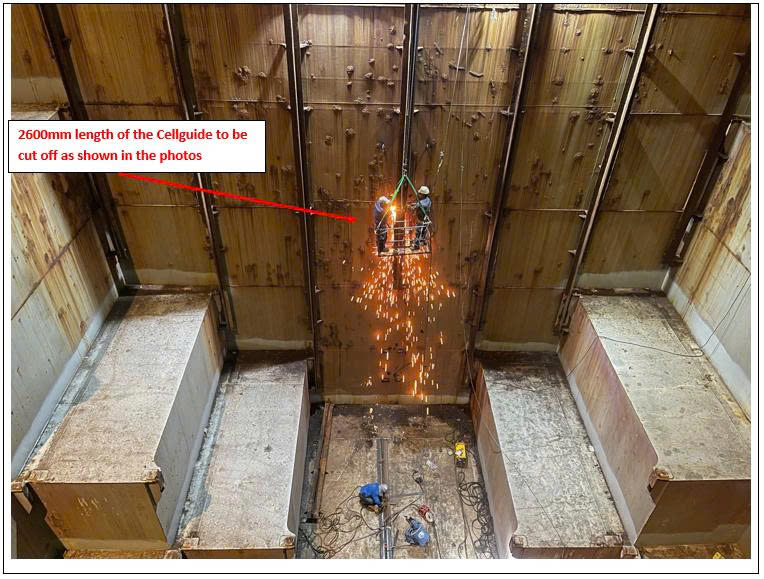

Cell Guide Replacement at Cai Mep Port

Cell Guide Replacement at Cai Mep Port – Expert Marine Services by Vietnam Shiprepair

Are you seeking reliable Marine Services for Time efficiency, The best Standard on your Feeder-type container ship at Cai Mep Port, but concerned about downtime and tight schedules? Vietnam Shiprepair Co. excels in Ship Repair and Marine Services, delivering high-quality solutions with an emphasis on time efficiency. In September 2025, we successfully completed a cell guide replacement of a 9-meter section in one cargo hold of a Feeder container ship at Cai Mep Port, finishing in just 9 hours while adhering to International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards. Our Marine Services span major Vietnamese ports like Nghi Son, Vung Tau, and Ho Chi Minh City. Trust our Vietnam Workshop for rapid, safe, and professional repairs—learn more at IACS Standards.

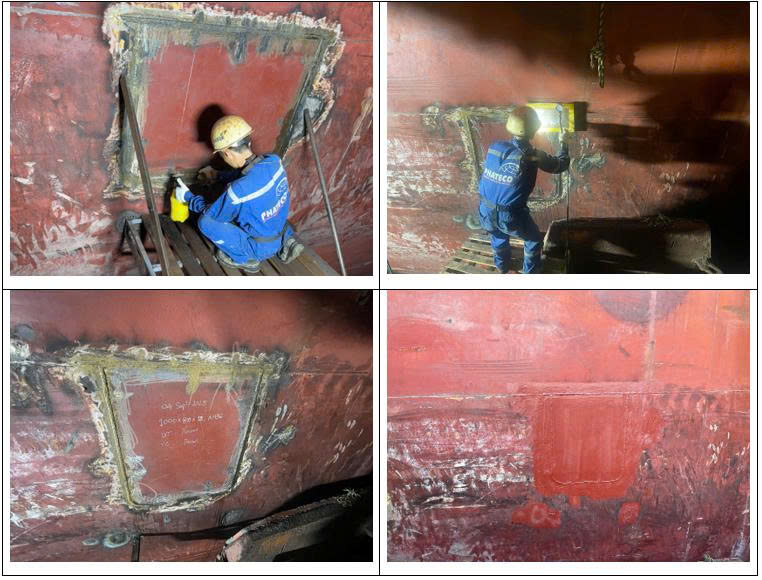

Feeder container ship undergoing cell guide replacement in hold at Cai Mep Port.

Feeder container ship undergoing cell guide replacement in hold at Cai Mep Port.

Importance of Cell Guide Replacement in Feeder Container Ships

Cell guides are critical vertical steel rails in the cargo holds of Feeder-type container ships (500-3,000 TEU), ensuring containers are securely stacked and aligned to prevent shifting during transit. At Cai Mep Port, a key deep-water hub in Vietnam, these structures face corrosion and wear due to high humidity and saline conditions. A cell guide replacement is vital to maintain vessel stability, protect cargo (e.g., electronics or textiles), and ensure seamless loading operations. Time efficiency in cell guide replacement is paramount for container ships, as even a few hours of delay can disrupt tight schedules and lead to significant financial losses. Vietnam Shiprepair’s Marine Services deliver rapid repairs, ensuring IACS/IMO compliance and minimal downtime at this bustling port.

Why Choose Professional Cell Guide Replacement?

Professional cell guide replacement prevents structural failures that could damage containers or compromise safety. Replacing a 9-meter section requires precision welding, alignment, and testing to meet IACS UR S11 standards. Our Vietnam Workshop leverages advanced techniques to complete repairs in just 9 hours, critical for Feeder ships on short-haul routes at Cai Mep Port. This rapid turnaround ensures compliance with IMO SOLAS Chapter II-1, safeguarding cargo and vessel seaworthiness while keeping schedules intact.

Steps to Perform Cell Guide Replacement in Container Ship Hold

Vietnam Shiprepair recently executed a cell guide replacement of a 9-meter section in the cargo hold of a Feeder container ship at Cai Mep Port, following strict IACS/IMO protocols. Here’s the streamlined process:

-

Preparation and Assessment

Our Vietnam Workshop team assesses the damaged cell guide using visual checks and Ultrasonic Testing to confirm corrosion or deformation. We coordinate with the crew at Cai Mep Port’s Thi Vai or CMIT terminals, preparing welding equipment, cranes, and scaffolding for swift and safe hold access. -

Safe Dismantling

Erect sturdy scaffolding to access the 9-meter height in the hold (6-12m total). Using chain blocks and cutting torches, carefully remove the faulty cell guide section, ensuring no damage to adjacent structures. -

Fabrication and Installation

Fabricate a new 9-meter cell guide from high-strength steel in our Vietnam Workshop, coated with anti-corrosion epoxy to withstand Cai Mep’s saline environment. Weld the new guide into place with precise alignment for seamless container stacking. -

Welding and Reinforcement

Perform certified welding on joints, followed by Ultrasonic Testing to verify weld integrity and alignment, ensuring durability under heavy loads. -

Final Testing and Certification

Conduct load tests and inspections to confirm stability. Generate a detailed report for classification societies like NK or DNV, securing IACS/IMO compliance. The 9-hour process allowed the vessel to resume operations without delay, critical for maintaining tight schedules at Cai Mep Port.

Vietnam Workshop team performing cell guide replacement in container ship hold at Cai Mep Port.

Vietnam Workshop team performing cell guide replacement in container ship hold at Cai Mep Port.

Safety and Time Efficiency in Marine Services

Replacing cell guides in confined holds at Cai Mep Port requires stringent safety and speed. Vietnam Shiprepair’s Marine Services adhere to IMO safety guidelines, using full PPE (harnesses, respirators, helmets), ventilation systems, and dual supervision. We monitor Cai Mep’s coastal weather to avoid disruptions, ensuring rapid execution to prevent costly delays. Our 9-hour cell guide replacement exemplifies our commitment to time efficiency, vital for Feeder ships on high-frequency routes.

Vietnam Shiprepair’s Nationwide Marine Services Network

Our Marine Services cover Vietnam’s key maritime hubs:

-

Cai Mep Port: A deep-water hub ideal for Feeder ship repairs, as shown in our recent cell guide project.

-

Nghi Son Anchorage: A center for efficient Ship Repair solutions.

-

Nationwide Reach: Serving Vung Tau, Ho Chi Minh City, and all ports/anchorages.

-

Mobile Operations: Our Vietnam Workshop brings advanced tools to your vessel.

-

Rapid Response: Swift deployment minimizes downtime.

Explore our offerings at Vietnam Shiprepair Services.

Benefits of Choosing Vietnam Shiprepair for Cell Guide Replacement

Choosing Vietnam Shiprepair for Marine Services offers:

-

IACS/IMO-compliant cell guide replacement, ensuring hold integrity and cargo safety.

-

Rapid 9-hour turnaround, critical for Feeder ship schedules at Cai Mep Port.

-

Cost-effective repairs, preventing extensive damage from faulty cell guides.

-

Skilled Vietnam Workshop technicians with over 20 years of expertise.

-

Detailed reports, enhancing vessel reliability and client trust.

Image placeholder 3: Feeder container ship after cell guide replacement, operating smoothly at Cai Mep Port. Alt text: Feeder ship post-cell guide replacement in stable operation.

Vietnam Shiprepair’s Commitment to Excellence

Our process—from assessment to certification—integrates expert personnel, advanced tools like Ultrasonic Testing, and strict IACS/IMO compliance. Supervised by classification societies, our Vietnam Workshop delivers flawless cell guide replacement, minimizing downtime and satisfying demanding clients. Trust Vietnam Shiprepair for superior Marine Services at Cai Mep Port!

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, Ho Chi Minh City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

Archives

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |

Categories

- News (9)

- Project Updates (105)