- by Vietnam Ship Repair

- 0

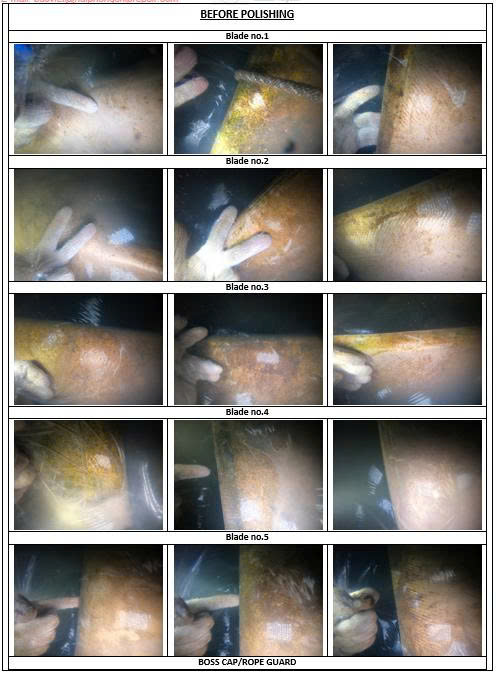

Propeller Polishing at Da Nang Port

Polishing at Da Nang Port

June 04, 2025, and your container ship is docked at Da Nang Port. The propeller is fouled with marine growth, reducing efficiency and risking costly repairs. Vietnam ShipRepair provides expert Underwater Cleaning and Propeller Polishing, serving Da Nang Port and across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. Our services ensure your vessel operates smoothly and meets global standards.

A Vietnam ShipRepair diver inspecting a fouled propeller at Da Nang Port.

A Vietnam ShipRepair diver inspecting a fouled propeller at Da Nang Port.

The Vital Importance of Propeller Polishing for Container Ships

Propeller polishing is critical for container ships, maintaining propeller efficiency by removing marine growth and corrosion. At Da Nang Port, where vessels face constant exposure to seawater, a fouled propeller increases fuel consumption, reduces speed, and strains the engine, potentially leading to mechanical failures. Regular Underwater Cleaning and Propeller Polishing prevent these issues, ensuring compliance with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards, while safeguarding vessel performance.

Benefits of Propeller Polishing and Underwater Cleaning

Investing in Underwater Cleaning and Propeller Polishing offers significant operational and economic benefits:

-

Improved Vessel Efficiency: Polished propellers reduce drag, lowering fuel use and enhancing speed at Nghi Son or Vung Tau.

-

Prevention of Damage: Regular cleaning prevents corrosion and mechanical strain, avoiding expensive repairs.

-

Cost Savings: Timely maintenance reduces the risk of major breakdowns, saving on long-term costs.

-

Regulatory Compliance: Adherence to IMO and IACS standards ensures your vessel passes inspections.

Vietnam ShipRepair’s expertise maximizes efficiency, prevents damage, and ensures compliance. Learn more about IMO guidelines here.

Vietnam ShipRepair team performing Propeller Polishing at Ho Chi Minh City port.

Vietnam ShipRepair team performing Propeller Polishing at Ho Chi Minh City port.

Our Underwater Cleaning and Propeller Polishing Process

Vietnam ShipRepair follows a precise process for Underwater Cleaning and Propeller Polishing, ensuring quality and compliance:

-

Initial Inspection: Divers assess propeller condition underwater using specialized equipment.

-

Cleaning and Polishing: We remove marine growth and polish the propeller with marine-grade tools.

-

Quality Check: Engineers verify smoothness and alignment, adhering to IMO and IACS standards.

-

Final Deployment: The propeller is reinstalled, ready for use at Da Nang Port.

This process guarantees optimal performance across Vietnam. Visit Vietnam ShipRepair Services for more details.

Why Vietnam ShipRepair is Your Trusted Partner

With over 20 years of experience, Vietnam ShipRepair excels in maritime solutions. We provide Underwater Cleaning and Propeller Polishing at:

-

Da Nang Port

-

Nghi Son Port and Anchorage

-

Vung Tau Anchorage

-

Ho Chi Minh City Ports and Anchorage

Our workshops and dive teams in Hai Phong and Ho Chi Minh City use advanced technology, ensuring IMO and IACS compliance. Ship operators trust our reliability and nationwide coverage for peace of mind.

A polished propeller in action at Vung Tau port. Alt text: Polished propeller on container ship.

A polished propeller in action at Vung Tau port. Alt text: Polished propeller on container ship.

Enhance Your Voyage with Vietnam ShipRepair

Don’t let a fouled propeller hinder your operations. Choose Vietnam ShipRepair for expert Underwater Cleaning and Propeller Polishing at Da Nang Port and beyond. Contact us now at 05:15 PM on June 04, 2025, to schedule your service and ensure a more efficient, damage-free journey.

Choose Vietnam Shiprepair for efficient, reliable Underwater Cleaning and Propeller Polishing that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

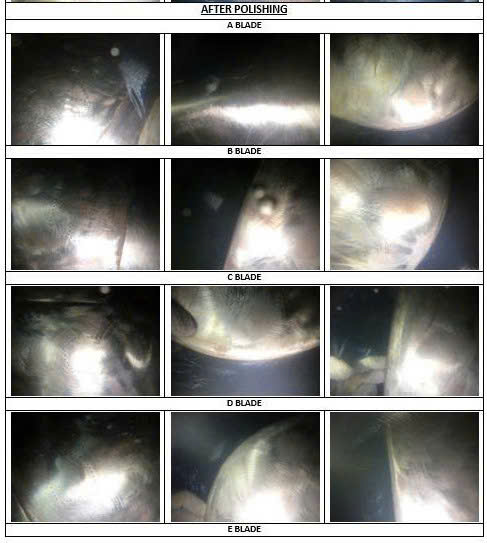

Cell Guide Repair for Container Ships at Da Nang Port

Cell Guide Repair for Container Ships at Da Nang Port

It’s 03:54 PM on Friday, May 23, 2025, and your container ship is docked at Da Nang Port. The cell guide system is damaged, risking cargo misalignment and operational delays. Vietnam ShipRepair offers expert Cell Guide Repair and Steel Works, providing reliable solutions at Da Nang Port and across Vietnam, including Nghi Son, Vung Tau, and Ho Chi Minh City. Our services ensure your vessel remains efficient and compliant with global standards.

Vietnam ShipRepair technician inspecting a damaged cell guide at Da Nang Port.

Vietnam ShipRepair technician inspecting a damaged cell guide at Da Nang Port.

The Critical Importance of Cell Guide Repair for Container Ships

Cell guides are vital for container ships, securing cargo within holds to prevent shifting during transit. At Da Nang Port, where high cargo volumes demand precision, damaged guides can lead to container damage, safety hazards, and non-compliance with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards. Timely Cell Guide Repair and Steel Works are essential to maintain structural integrity, protect cargo, and ensure smooth operations.

Benefits of Timely Cell Guide Repair and Steel Works

Investing in Steel Works delivers significant operational and economic advantages:

-

Enhanced Operational Efficiency: Repaired guides ensure secure cargo handling, speeding up loading at Nghi Son or Vung Tau.

-

Reduced Downtime: Quick repairs prevent delays, keeping schedules on track.

-

Cost Savings: Timely maintenance avoids extensive repairs or replacements, lowering expenses.

-

Regulatory Compliance: Adherence to IMO and IACS standards ensures your vessel passes inspections.

Vietnam ShipRepair’s expertise maximizes productivity, savings, and compliance. Learn more about IMO standards here.

Vietnam ShipRepair team performing Steel Works on a cell guide at Da Nang port.

Vietnam ShipRepair team performing Steel Works on a cell guide at Da Nang port.

Our Cell Guide Repair and Steel Works Process

Vietnam ShipRepair follows a rigorous process for Cell Guide Repair and Steel Works, ensuring quality and compliance:

-

Detailed Inspection: Technicians assess damage using advanced tools to identify structural issues.

-

Material Selection: We use high-strength steel designed for marine conditions.

-

Precision Repair: Engineers reinforce or replace guides, adhering to IMO and IACS standards.

-

Testing and Installation: Each guide is tested and reinstalled, ready for use at Da Nang Port.

This process guarantees reliable performance across Vietnam. Visit Vietnam ShipRepair Services for more details.

Why Vietnam ShipRepair is Your Trusted Partner

With over 20 years of experience, Vietnam ShipRepair leads in maritime solutions. We provide Steel Works at:

-

Da Nang Port

-

Nghi Son Port and Anchorage

-

Vung Tau Anchorage

-

Ho Chi Minh City Ports and Anchorage

Our workshops in Hai Phong and Ho Chi Minh City leverage cutting-edge technology, ensuring IMO and IACS compliance. Ship operators trust our reliability and nationwide coverage for peace of mind.

A repaired cell guide securing containers at Da Nang port.

A repaired cell guide securing containers at Da Nang port.

Secure Your Voyage with Vietnam ShipRepair

Don’t let damaged cell guides disrupt your operations. Choose Vietnam ShipRepair for expert Cell Guide Repair and Steel Works at Da Nang Port and beyond.

Choose Vietnam Shiprepair for efficient, reliable Cell Guide Repair and Steel Works that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

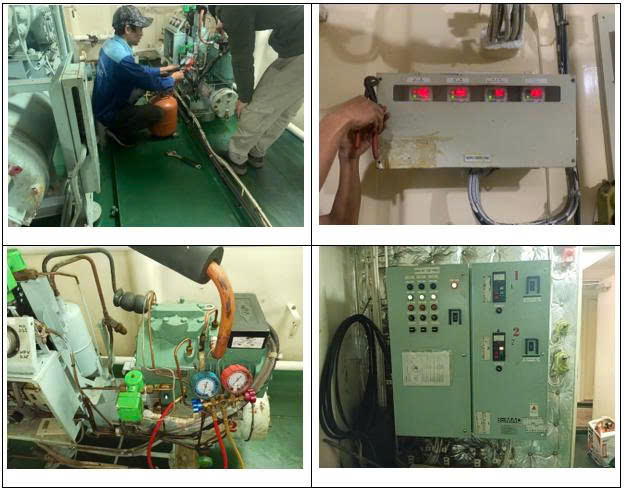

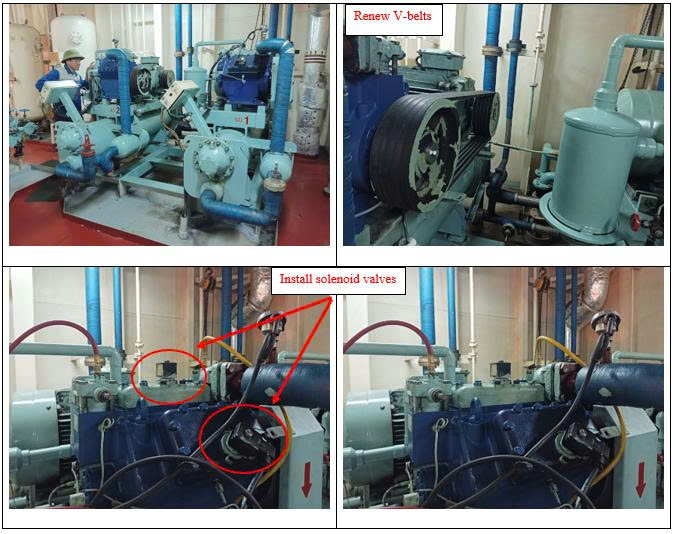

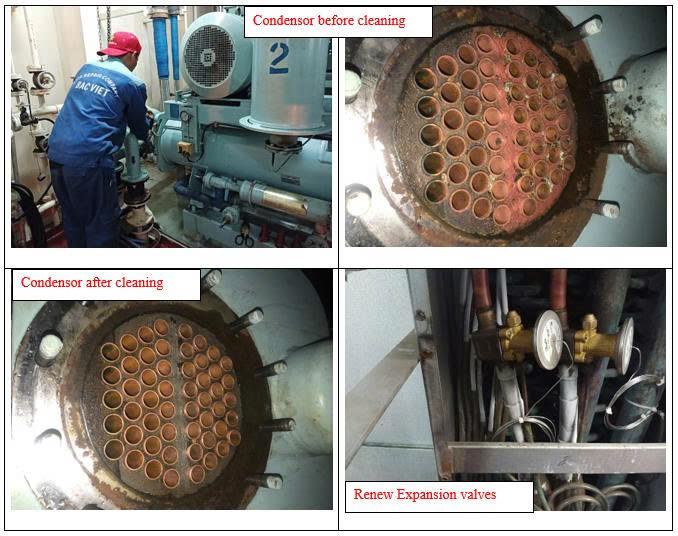

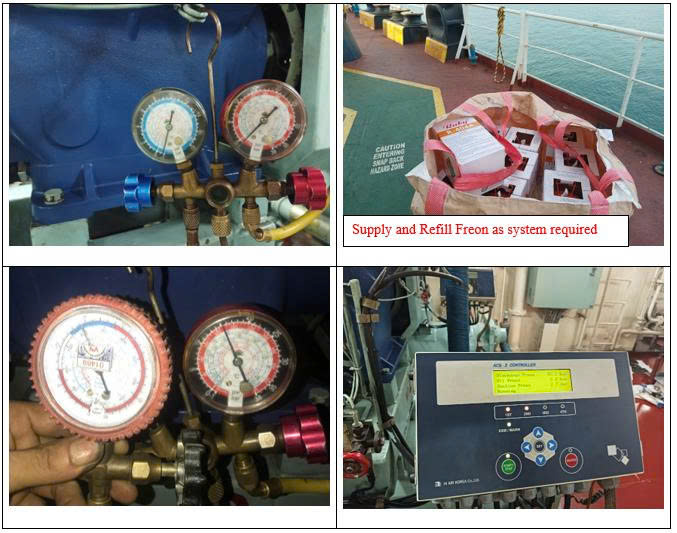

Refrigeration Repair for Provision Storage at Van Phong Anchorage

Refrigeration Repair for Provision Storage at Van Phong Anchorage

It’s 03:40 AM on Friday, May 09, 2025, and your vessel is anchored at Van Phong Anchorage. The refrigeration unit for provision storage fails, threatening food safety and crew well-being. Vietnam ShipRepair delivers expert Refrigeration Repair and Provision Storage maintenance, serving Van Phong Anchorage and ports across Vietnam, including Da Nang, Nghi Son, Vung Tau, and Ho Chi Minh City. Our services ensure your crew stays supported and your vessel remains compliant.

Technician checking refrigeration unit for provision storage.

Technician checking refrigeration unit for provision storage.

The Crucial Role of Provision Storage on Bulk Carriers

Provision storage, supported by reliable refrigeration, is vital for bulk carriers, preserving food and supplies for long voyages. At Van Phong Anchorage, where vessels may remain for extended periods, a functioning refrigeration system prevents spoilage, ensuring crew health and morale. A failing unit can lead to food loss, health risks, and non-compliance with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards. Timely Refrigeration Repair and Provision Storage maintenance are essential to uphold operational integrity.

Benefits of Timely Refrigeration Repair and Maintenance

Investing in Refrigeration Repair and Provision Storage maintenance offers significant operational and economic benefits:

-

Enhanced Crew Welfare: Repaired units maintain food freshness, boosting crew health and productivity at Da Nang or Vung Tau.

-

Reduced Downtime: Quick repairs prevent operational delays, keeping schedules on track.

-

Cost Savings: Regular maintenance avoids major replacements, lowering long-term expenses.

-

Regulatory Compliance: Adherence to IMO and IACS standards ensures inspection success.

Vietnam ShipRepair’s expertise maximizes efficiency, savings, and compliance. Explore IMO guidelines here.

Vietnam ShipRepair team performing Refrigeration Repair at Ho Chi Minh City port.

Vietnam ShipRepair team performing Refrigeration Repair at Ho Chi Minh City port.

Our Refrigeration Repair and Maintenance Process

Vietnam ShipRepair follows a meticulous process for Refrigeration Repair and Provision Storage maintenance, ensuring quality and compliance:

-

Thorough Inspection: Technicians assess the refrigeration system for faults using advanced diagnostics.

-

Component Replacement: We use high-quality parts designed for marine environments.

-

Expert Repair: Engineers restore or maintain units, adhering to IMO and IACS standards.

-

Testing and Optimization: Each system is tested and recommissioned, ready for use at Van Phong Anchorage.

This process guarantees reliable performance across Vietnam. Visit Vietnam ShipRepair Services for more details.

Why Vietnam ShipRepair is Your Trusted Partner

With over 20 years of experience, Vietnam ShipRepair excels in maritime solutions.

Choose Vietnam Shiprepair for efficient, reliable Refrigeration Repair and Provision Storage that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

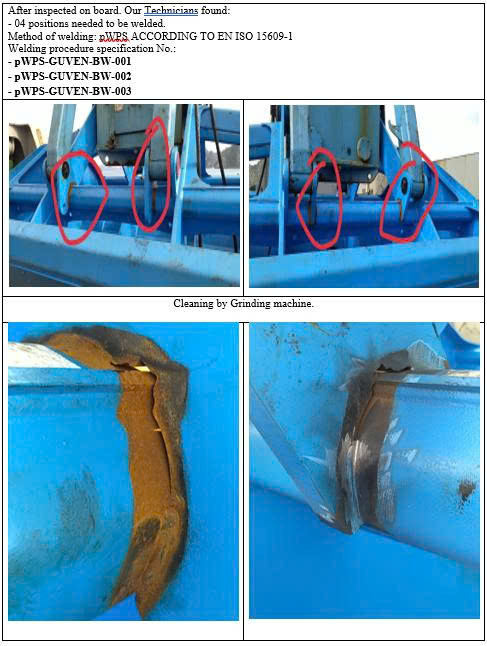

Grab Repairs for Bulk Carriers at Quy Nhon Port

Grab Repairs for Bulk Carriers at Quy Nhon Port

It’s 09:04 AM , April 06, 2025, and your bulk carrier is docked at Quy Nhon Port. The cargo grab malfunctions, halting loading operations and risking costly delays. Vietnam ShipRepair offers expert Grab Repairs and Steel Works, providing reliable solutions at Quy Nhon Port and across Vietnam, including Da Nang, Nghi Son, Vung Tau, and Ho Chi Minh City. Our services ensure your vessel stays operational and compliant with global standards.

A Vietnam ShipRepair technician inspecting a damaged cargo grab at Quy Nhon Port.

A Vietnam ShipRepair technician inspecting a damaged cargo grab at Quy Nhon Port.

The Vital Role of Cargo Grabs on Bulk Carriers

Cargo grabs are essential for bulk carriers, enabling efficient loading and unloading of materials like coal, grain, and ore. At Quy Nhon Port, where high throughput is critical, a damaged grab can disrupt operations, leading to delays and safety risks. Worn-out or broken grabs may also cause cargo spillage, environmental hazards, and non-compliance with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards. Timely Grab Repairs and Steel Works are crucial to maintain efficiency and safety.

Benefits of Timely Grab Repairs and Steel Works

Investing in Grab Repairs and Steel Works delivers significant operational and economic advantages:

-

Improved Efficiency: Repaired grabs ensure smooth cargo handling, speeding up operations at Da Nang or Vung Tau.

-

Reduced Downtime: Quick repairs prevent prolonged delays, keeping schedules on track.

-

Cost Savings: Timely maintenance avoids major replacements, lowering expenses.

-

Regulatory Compliance: Adherence to IMO and IACS standards ensures your vessel passes inspections.

Vietnam ShipRepair’s expertise maximizes productivity, savings, and compliance. Learn more about IMO regulations here.

Team repairing cargo grab on ship.

Team repairing cargo grab on ship.

Our Grab Repairs and Steel Works Process

Vietnam ShipRepair follows a precise process for Grab Repairs and Steel Works, ensuring quality and compliance:

-

Detailed Inspection: Technicians assess the grab for structural damage or wear.

-

Material Selection: We use high-grade steel to withstand heavy-duty operations.

-

Expert Repair: Engineers perform repairs or reinforcements, adhering to IMO and IACS standards +

-

Testing and Delivery: Each grab is tested and reinstalled, ready for use at Quy Nhon Port.

This process guarantees reliable performance across Vietnam. Visit Vietnam ShipRepair Services for more details.

Why Vietnam ShipRepair is Your Trusted Partner

With over 20 years of experience, Vietnam ShipRepair leads in maritime solutions. We provide Grab Repairs and Steel Works at:

-

Quy Nhon Port

-

Da Nang Port and Anchorage

-

Nghi Son Port and Anchorage

-

Vung Tau Anchorage

-

Ho Chi Minh City Ports and Anchorage

Our workshops in Hai Phong and Ho Chi Minh City use advanced technology, ensuring IMO and IACS compliance. Ship operators trust our reliability and nationwide coverage for peace of mind.

A fully repaired cargo grab in action at Vung Tau port.

A fully repaired cargo grab in action at Vung Tau port.

Keep Operations Smooth with Vietnam ShipRepair

Don’t let a damaged cargo grab disrupt your workflow. Trust Vietnam ShipRepair for expert Grab Repairs and Steel Works at Quy Nhon Port and beyond.

Choose Vietnam Shiprepair for efficient, reliable Piping Repair and Piping Install that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

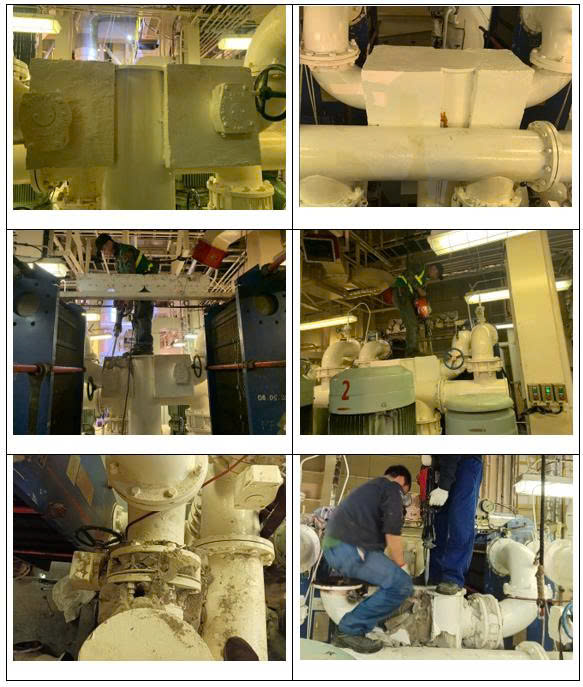

Piping Install for Seawater Cooling Pipes at Phu My Port

Piping Install for Seawater Cooling Pipes at Phu My Port

It’s 01:40 AM on Sunday, June 06, 2025, and your bulk carrier is docked at Phu My Port. The seawater cooling pipe fails, risking engine overheating and operational delays. Vietnam ShipRepair specializes in Piping Repair and Piping Install, providing reliable solutions at Phu My Port and across Vietnam, including Da Nang, Nghi Son, Vung Tau, and Ho Chi Minh City. Our expertise ensures your vessel stays cool, compliant, and operational.

Vietnam ShipRepair technician inspecting a damaged seawater cooling pipe at Phu My Port. Technician examining seawater cooling pipe on bulk carrier.

Vietnam ShipRepair technician inspecting a damaged seawater cooling pipe at Phu My Port. Technician examining seawater cooling pipe on bulk carrier.

Importance of Seawater Cooling Pipes on Bulk Carriers

Seawater cooling pipes are vital for bulk carriers, circulating seawater to regulate engine temperatures and prevent overheating. At Phu My Port, where vessels face constant saltwater exposure, these pipes are prone to corrosion, leaks, and blockages. A failing pipe can lead to engine failure, costly downtime, and non-compliance with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards. Regular Piping Repair and timely Piping Install are essential to maintain engine performance and safety.

Benefits of Piping Repair and Piping Install

Investing in Piping Repair and Piping Install offers significant operational and economic benefits:

-

Improved Engine Efficiency: New or repaired pipes ensure optimal cooling, enhancing engine performance at Da Nang or Vung Tau.

-

Minimized Downtime: Proactive maintenance prevents unexpected failures, keeping operations on schedule.

-

Cost Savings: Regular repairs extend pipe lifespan, reducing the need for frequent replacements.

-

Regulatory Compliance: Adherence to IMO and IACS standards ensures your vessel passes inspections.

Vietnam ShipRepair’s services deliver efficiency, savings, and compliance. Learn more about IMO regulations here.

Team fabricating seawater cooling pipe on Board.

Team fabricating seawater cooling pipe on Board.

Our Piping Repair and Piping Install Process

Vietnam ShipRepair follows a precise process for Piping Repair and Piping Install, ensuring quality and compliance:

-

Thorough Assessment: Technicians inspect pipes for corrosion or damage using advanced tools.

-

Material Selection: We use corrosion-resistant materials designed for marine environments.

-

Expert Execution: Engineers perform repairs or new installations, adhering to IMO and IACS standards.

-

Testing and Commissioning: Each pipe is tested and installed, ready for use at Phu My Port.

This process guarantees reliable performance across Vietnam. Visit Vietnam ShipRepair Services for more details.

Why Choose Vietnam ShipRepair for Piping Services

With over 20 years of experience, Vietnam ShipRepair is a trusted leader in maritime solutions. We provide Piping Repair and Piping Install at:

-

Phu My Port

-

Da Nang Port and Anchorage

-

Nghi Son Port and Anchorage

-

Vung Tau Anchorage

-

Ho Chi Minh City Ports and Anchorage

Our workshops in Hai Phong and Ho Chi Minh City use state-of-the-art technology, ensuring IMO and IACS compliance. Ship operators rely on our expertise and nationwide coverage for peace of mind.

A newly installed seawater cooling pipe on a bulk carrier at Vung Tau port.

Keep Your Vessel Cool with Vietnam ShipRepair

Don’t let a failing seawater cooling pipe disrupt your journey. Trust Vietnam ShipRepair for expert Piping Repair and Piping Install at Phu My Port and beyond.

Choose Vietnam Shiprepair for efficient, reliable Piping Repair and Piping Install that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Turbocharger Renewal for Generator at Cam Pha Anchorage

Turbocharger Renewal for Generator at Cam Pha Anchorage

Imagine your bulk carrier anchored at Cam Pha Anchorage when suddenly the generator’s turbocharger fails, leaving the vessel without power. The crew scrambles as operations grind to a halt, risking delays and costly penalties. At Vietnam ShipRepair, we understand these high-stakes challenges. That’s why we specialize in Turbocharger Renewal and Turbocharger Overhauling, offering reliable solutions at Cam Pha Anchorage and ports across Vietnam, including Da Nang, Nghi Son, Vung Tau, and Ho Chi Minh City. Let’s keep your vessel powered and compliant with Vietnam ShipRepair.

Technician examining turbocharger on ship.

Technician examining turbocharger on ship.

Why Turbochargers Are Vital for Bulk Carrier Generators

A turbocharger is the heart of a bulk carrier’s generator, boosting engine power and efficiency by forcing extra air into the combustion chamber. On vessels operating in demanding conditions at Cam Pha Anchorage, a well-functioning turbocharger ensures consistent power supply for critical systems like lighting, navigation, and cargo handling. A failing turbocharger can lead to power shortages, engine strain, and even complete shutdowns, jeopardizing safety and operations. Regular Turbocharger Overhauling and timely renewal are essential to maintain performance, prevent downtime, and comply with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards.

Benefits of Turbocharger Renewal and Overhauling

Investing in Turbocharger Renewal and Turbocharger Overhauling delivers significant operational and economic advantages for ship operators:

-

Improved Efficiency: A renewed turbocharger enhances fuel combustion, optimizing generator output and reducing fuel consumption.

-

Minimized Downtime: Proactive overhauling at ports like Da Nang or Vung Tau prevents unexpected failures, ensuring uninterrupted operations.

-

Cost Savings: Regular maintenance extends the turbocharger’s lifespan, avoiding expensive emergency repairs or replacements.

-

Regulatory Compliance: Adhering to IMO and IACS standards ensures your vessel passes inspections, avoiding fines and delays.

By prioritizing turbocharger maintenance with Vietnam ShipRepair, you safeguard your vessel’s performance and profitability.

Team turbocharger renewal on bulk carrier.

Team turbocharger renewal on bulk carrier.

Our Turbocharger Renewal Process

Vietnam ShipRepair delivers expert Turbocharger Renewal and Turbocharger Overhauling with a streamlined process, ensuring quality and compliance:

-

Inspection and Diagnosis: Our technicians assess the turbocharger’s condition, identifying wear or damage.

-

Component Sourcing: We use high-quality, marine-grade parts designed for durability in harsh conditions.

-

Renewal and Overhauling: Skilled engineers replace or refurbish components, adhering to IMO and IACS guidelines.

-

Testing and Installation: Each turbocharger undergoes rigorous testing before reinstallation at Cam Pha Anchorage, ensuring optimal performance.

This meticulous process guarantees your generator operates reliably, supporting your vessel’s operations nationwide.

Why Choose Vietnam ShipRepair for Turbocharger Services

For over 20 years, Vietnam ShipRepair has been a trusted partner for maritime solutions across Vietnam. We provide Turbocharger Renewal and Turbocharger Overhauling at all major ports, including:

-

Cam Pha Anchorage

-

Da Nang Port and Anchorage

-

Nghi Son Port and Anchorage

-

Vung Tau Anchorage

-

Ho Chi Minh City Ports and Anchorage

Our commitment to IMO and IACS standards, combined with state-of-the-art workshops in Hai Phong and Ho Chi Minh City, ensures top-quality service. Ship operators rely on us for our expertise, nationwide coverage, and customer-focused approach. Learn more about IACS standards on their official site here.

Renewed turbocharger on ship generator.

Renewed turbocharger on ship generator.

Power Your Vessel with Confidence

Don’t let a failing turbocharger disrupt your operations. Partner with Vietnam ShipRepair for expert Turbocharger Renewal and Turbocharger Overhauling at Cam Pha Anchorage and beyond. Contact us today to schedule your service and ensure a more efficient, compliant, and reliable journey.

Choose Vietnam Shiprepair for efficient, reliable Turbocharger Renewal and Turbocharger Overhauling that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Central Air Condition Repairing at Cam Pha Anchorage

Central Air Condition Repairing at Cam Pha Anchorage

In the demanding maritime industry, maintaining optimal working conditions on bulk carriers is critical for crew efficiency and operational success. A key component in achieving this is the central air conditioning system, which ensures a comfortable environment in the harsh conditions of the sea. At Cam Pha Anchorage, as well as ports across Vietnam such as Da Nang Port, Nghi Son Port, Vung Tau, and Ho Chi Minh City, Vietnam ShipRepair provides top-tier Central Air Condition Repairing and Central Air Condition Troubleshooting services, ensuring vessels remain in peak condition.

The Importance of Central Air Conditioning Systems on Bulk Carriers

Central air conditioning systems are the backbone of crew comfort and equipment functionality on bulk carriers. These systems regulate temperature, humidity, and air quality, creating a livable environment for crew members working long hours in challenging conditions. A well-functioning air conditioning system also protects sensitive onboard equipment from overheating, reducing the risk of costly breakdowns. Without proper maintenance, these systems can falter, leading to discomfort, reduced productivity, and potential operational delays.

At Cam Pha Anchorage, where vessels often face extreme weather conditions, a reliable air conditioning system is not just a luxury but a necessity. Regular maintenance and timely repairs ensure that the system operates efficiently, maintaining a stable environment that supports both crew welfare and cargo integrity.

A technician from Vietnam ShipRepair inspecting a central air conditioning unit on a bulk carrier at Cam Pha Anchorage.

A technician from Vietnam ShipRepair inspecting a central air conditioning unit on a bulk carrier at Cam Pha Anchorage.

Benefits of Regular Maintenance and Repair

Routine Central Air Condition Repairing and maintenance offer significant operational and economic benefits for ship operators. Here’s how:

-

Enhanced Operational Efficiency: A well-maintained air conditioning system runs smoothly, reducing energy consumption and preventing unexpected failures. This ensures vessels remain operational without costly downtime.

-

Cost Savings: Preventive maintenance and troubleshooting address minor issues before they escalate into major, expensive repairs. Regular servicing extends the lifespan of the system, reducing the need for frequent replacements.

-

Improved Crew Performance: A comfortable working environment boosts crew morale and productivity. Properly functioning air conditioning systems prevent heat-related stress, ensuring the crew can focus on their tasks.

-

Compliance with Regulations: Regular maintenance ensures that air conditioning systems meet the standards set by international organizations like the International Maritime Organization (IMO) and the International Association of Classification Societies (IACS), avoiding penalties and ensuring safe operations.

By investing in routine Central Air Condition Troubleshooting, ship operators can mitigate risks, reduce operational costs, and maintain compliance with global maritime standards.

A Vietnam ShipRepair team performing routine maintenance on a bulk carrier’s air conditioning system at Cam Pha Anchorage.

A Vietnam ShipRepair team performing routine maintenance on a bulk carrier’s air conditioning system at Cam Pha Anchorage.

Why Choose Vietnam ShipRepair?

When it comes to Central Air Condition Repairing, selecting a trusted and experienced service provider is crucial. Vietnam ShipRepair stands out as a leading choice for ship operators across Vietnam, from Cam Pha Anchorage to ports in Vung Tau, Ho Chi Minh City, and beyond. Here’s why:

-

Expertise and Experience: Vietnam ShipRepair employs highly skilled technicians with extensive knowledge of maritime air conditioning systems. Their expertise ensures accurate diagnostics and efficient repairs, minimizing downtime.

-

Nationwide Coverage: With services available at all major anchorages and ports in Vietnam, including Cam Pha, Da Nang, Nghi Son, and Vung Tau, Vietnam ShipRepair offers unmatched accessibility and convenience.

-

Adherence to International Standards: All repair and maintenance processes comply with strict guidelines set by the IMO and IACS, ensuring quality and safety. This commitment to excellence guarantees that every repair meets global benchmarks.

-

Customer-Centric Approach: Vietnam ShipRepair prioritizes customer satisfaction, offering tailored solutions, transparent pricing, and prompt service. Their reputation for reliability makes them a trusted partner for ship operators nationwide.

Choosing Vietnam ShipRepair means choosing peace of mind, knowing that your vessel’s air conditioning system is in capable hands.

A successfully repaired central air conditioning unit on a bulk carrier, ready to operate efficiently at Cam Pha Anchorage.

A successfully repaired central air conditioning unit on a bulk carrier, ready to operate efficiently at Cam Pha Anchorage.

Commitment to International Standards

Vietnam ShipRepair’s repair processes are designed to meet the rigorous standards of international maritime organizations. By adhering to IMO and IACS guidelines, the company ensures that all repairs and maintenance activities Hawkins not only ensures compliance with these standards but also enhances the safety and reliability of the vessel’s air conditioning system.

Conclusion

For bulk carriers operating at Cam Pha Anchorage or any port across Vietnam, a reliable central air conditioning system is essential for operational success and crew well-being. By partnering with Vietnam ShipRepair for Central Air Condition Repairing and Central Air Condition Troubleshooting, ship operators can ensure their systems run efficiently, comply with international standards, and deliver long-term economic and operational benefits. Contact Vietnam ShipRepair today to schedule your maintenance or repair services and experience the peace of mind that comes with working with a trusted industry leader.

Choose Vietnam Shiprepair for efficient, reliable Central Air Condition Repairing that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Steering Gear Ram Replacement for Container Vessel at Danang Terminal

Steering Gear Ram Replacement for Container Vessel

at Danang Terminal

Is your container vessel facing steering gear issues at Danang Terminal or Vung Tau, Vietnam? Vietnam Shiprepair Co. offers professional Steering Gear Ram Replacement and Hydraulic Cylinder Overhauling services to restore your vessel’s steering system to optimal performance. We recently completed a seamless steering gear ram replacement for a Container Vessel at Danang Terminal. Moreover, Vietnam Shiprepair provides these services at all ports and anchorages across Vietnam, including Vung Tau, Cam Pha, Ho Chi Minh, and Hai Phong. Our work complies with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards, ensuring safety and reliability. Therefore, trust Vietnam Shiprepair for expert hydraulic cylinder repair and steering gear overhauling services nationwide!

Show Vietnam Shiprepair’s team replacing the steering gear ram on a Container Vessel

Show Vietnam Shiprepair’s team replacing the steering gear ram on a Container Vessel

I. Why Steering Gear Ram Replacement is Crucial for Container Vessels

The steering gear system is vital for a container vessel’s navigation, ensuring precise control and safety during voyages. A steering gear ram failure at Danang Terminal could lead to operational delays. Consequently, timely steering gear ram replacement is essential to maintain vessel functionality. Here’s why this service matters:

-

Restores Navigation Precision: Replacing a faulty ram ensures accurate steering, preventing navigation errors in busy ports like Haiphong Terminal.

-

Prevents System Failures: A damaged hydraulic cylinder can cause steering gear breakdowns, risking vessel safety. Furthermore, regular overhauling avoids such issues.

-

Enhances Safety: Faulty steering systems pose hazards to the crew and cargo. Therefore, Vietnam Shiprepair’s hydraulic cylinder repair ensures compliance with IACS and IMO standards.

-

Reduces Downtime: Swift replacement at Vung Tau or Danang Terminal minimizes delays, keeping cargo schedules on track.

-

Cost-Effective Solution: Repairing or replacing the ram is more economical than overhauling the entire system. Additionally, it extends the steering gear’s lifespan.

With Vietnam Shiprepair, your vessel’s steering gear is in expert hands, wherever it’s located in Vietnam.

II. Vietnam Shiprepair’s Nationwide Service Coverage

Vietnam Shiprepair Co. delivers steering gear overhauling and hydraulic cylinder repair services across all Vietnamese ports and anchorages:

-

Haiphong Terminal: Ideal for efficient repairs, as demonstrated with a recent Container Vessel.

-

Vung Tau, Vietnam: A key hub for quick, high-quality steering gear ram replacements.

-

Nationwide Reach: Services extend to Cam Pha, Ho Chi Minh, Hai Phong, and all anchorages nationwide.

-

Mobile Operations: We bring manpower, materials, and equipment directly to your vessel, minimizing logistical challenges.

-

Rapid Response: Fast deployment ensures minimal downtime, keeping your operations on schedule.

Display Vietnam Shiprepair’s team performing steering gear repairs at Danang Terminal

III. Scope of Steering Gear Ram Replacement for a Container Vessel

For a Container Vessel at Danang Terminal, Vietnam Shiprepair executed a steering gear ram replacement (No. 2 cylinder). Here’s how we ensured success:

-

Preparation: Arranged skilled manpower, materials, and equipment to board at Danang Port.

-

Inspection: Measured old and new cylinder ram dimensions for compatibility.

-

System Disassembly: Opened hydraulic systems, electric systems, sensors, gauges, and foundation bolts.

-

Support Setup: Built supports to move the old cylinder ram safely.

-

Installation: Installed the new cylinder ram (No. 2) with proper alignment.

-

Reinstallation: Reassembled all components with precision.

-

Testing: Conducted operational tests with the ship’s crew to confirm performance.

-

Permits & Logistics: Secured work permits from Port Authority and Terminal, plus boarding passes for manpower.

This process ensured the Container Vessel’s steering gear was fully operational, meeting IACS and IMO standards.

IV. Benefits of Timely Steering Gear Ram Replacement

Timely hydraulic cylinder overhauling and ram replacement keep your vessel operational:

-

Uninterrupted Operations: Quick repairs at Danang Terminal or Vung Tau prevent delays, ensuring on-time cargo delivery.

-

Enhanced Safety: Compliance with IACS and IMO standards reduces risks of steering-related incidents.

-

Cost Savings: Proactive replacement cuts repair costs by up to 35%, saving on downtime.

Vietnam Shiprepair ensures your steering gear performs reliably, protecting your schedule and budget.

V. Why Choose Vietnam Shiprepair for Steering Gear Services

Vietnam Shiprepair is Vietnam’s trusted leader in steering gear ram replacement and hydraulic cylinder repair, offering:

-

Expert Technicians: IACS-approved professionals with extensive experience.

-

Fast Service: Rapid response to any port, minimizing disruptions.

-

Custom Solutions: Tailored repairs for each vessel’s needs.

-

Global Compliance: Adherence to IACS and IMO standards.

-

Cost-Effective: High-quality services at competitive prices.

-

Nationwide Access: Services at Danang Terminal, Haiphong Port, Vung Tau, and all Vietnamese ports.

Contact us today for steering gear overhauling at any Vietnamese port!

Showcase the fully repaired steering gear system on a Container Vessel, highlighting Vietnam Shiprepair’s quality

Showcase the fully repaired steering gear system on a Container Vessel, highlighting Vietnam Shiprepair’s quality

VI. Vietnam Shiprepair’s Commitment to Excellence

Our streamlined process ensures top performance:

-

Inspection: Assess components for wear or damage.

-

Disassembly: Dismantle the system to identify issues.

-

Repair/Replacement: Fix or replace parts with precision.

-

Testing: Rigorous tests confirm compliance with IACS and IMO standards.

Choose Vietnam Shiprepair for efficient, reliable steering gear ram replacement that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Main Engine Overhauling at Cam Pha Anchorage

Main Engine Overhauling at Cam Pha Anchorage – Reliable Solutions with Vietnam Shiprepair

Is your bulk carrier’s main engine underperforming at Cam Pha Anchorage? Vietnam Shiprepair Co. delivers expert Main Engine Overhauling to restore power, efficiency, and safety. Additionally, we provide services at Cam Pha Anchorage, Quang Ninh, as well as Ho Chi Minh Port, Vung Tau Anchorage, Hai Phong Port, and all major ports across Vietnam. Furthermore, our overhauls comply with International Association of Classification Societies (IACS), International Maritime Organization (IMO), and maker standards, ensuring top-tier reliability. Therefore, choose Vietnam Shiprepair—Vietnam’s leading marine engineering provider—for your main engine overhauling needs!

Display a bulk carrier’s main engine being overhauled by Vietnam Shiprepair technicians at Cam Pha Anchorage

Display a bulk carrier’s main engine being overhauled by Vietnam Shiprepair technicians at Cam Pha Anchorage

I. Why Main Engine Overhauling Matters

The main engine is the backbone of your bulk carrier, driving propulsion and ensuring seamless operations. Overhauling is essential to maintain performance and prevent costly failures. Moreover, here’s why it’s critical:

-

Restores Peak Performance: Comprehensive disassembly, inspection, and repair of components like fuel injectors, turbochargers, pistons, and lubrication systems ensure optimal engine output.

-

Prevents Catastrophic Failures: Regular overhauling addresses wear and tear, avoiding unexpected breakdowns that disrupt cargo schedules. Consequently, this minimizes operational risks.

-

Boosts Fuel Efficiency: A well-overhauled engine reduces fuel consumption, lowering operational costs on long voyages. Additionally, this supports sustainable practices.

-

Ensures Safety: Faulty engines risk crew safety and vessel integrity; overhauling mitigates hazards in challenging conditions. Furthermore, it enhances overall vessel stability.

-

Meets Global Standards: Vietnam Shiprepair adheres to IACS, IMO, and maker guidelines, ensuring compliance and avoiding penalties. Therefore, your vessel remains inspection-ready.

-

Tailored Expertise: Our IACS-approved technicians at Cam Pha Anchorage deliver precise, vessel-specific overhauls for maximum reliability. Moreover, this personalized approach ensures long-term benefits.

Trust Vietnam Shiprepair to keep your main engine running smoothly, wherever your vessel operates.

II. Vietnam Shiprepair’s Nationwide Reach

Vietnam Shiprepair offers unmatched flexibility and expertise across Vietnam’s maritime hubs:

-

Cam Pha Anchorage: Ideal conditions with calm waters ensure efficient, high-quality overhauling. Additionally, this location supports rapid service delivery.

-

Nationwide Coverage: Services extend to Ho Chi Minh Port, Vung Tau Anchorage, Hai Phong Port, and all Vietnamese ports/anchorages. Furthermore, this broad reach saves time.

-

Mobile Operations: Our shipyard-like capabilities bring overhauling services directly to your vessel, minimizing delays. Consequently, downtime is significantly reduced.

-

Skilled Team: IACS-approved engineers use advanced tools for reliable, compliant results. Moreover, their expertise ensures consistent quality.

-

Rapid Response: Fast deployment ensures minimal downtime, keeping your operations on track. Therefore, you can rely on us in any port.

Show Vietnam Shiprepair’s team overhauling a main engine at a Vietnamese port, highlighting nationwide service

III. Benefits of Timely Main Engine Overhauling

Timely overhauling keeps your bulk carrier operational and cost-efficient:

-

Uninterrupted Operations: Swift overhauls at Cam Pha Anchorage prevent delays, ensuring on-time cargo delivery.

-

Enhanced Safety: Compliance with IACS, IMO, and maker standards reduces risks of engine-related incidents.

-

Cost Savings: Proactive overhauling cuts repair costs by up to 40% compared to emergency fixes, saving on downtime and fuel.

Vietnam Shiprepair’s expertise ensures your engine performs reliably, protecting your schedule and budget.

IV. Why Choose Vietnam Shiprepair

Vietnam Shiprepair is Vietnam’s trusted leader in main engine overhauling, offering:

-

Expert Technicians: IACS-approved professionals with extensive experience in engine overhauls.

-

Fast Service: Quick response to any port, minimizing operational disruptions.

-

Custom Solutions: Tailored overhauls for each vessel’s unique requirements.

-

Global Compliance: Adherence to IACS, IMO, and maker standards, with detailed reports for inspections.

-

Cost-Effective: High-quality overhauls at competitive prices, maximizing value.

-

Nationwide Access: Services from Cam Pha to Vung Tau, Ho Chi Minh, and beyond.

With over 20 years of experience, Vietnam Shiprepair guarantees durable, compliant overhauls. Contact us today to schedule your main engine overhauling at Cam Pha Anchorage or any Vietnamese port!

Showcase a fully overhauled main engine, highlighting Vietnam Shiprepair’s quality and precision

Showcase a fully overhauled main engine, highlighting Vietnam Shiprepair’s quality and precision

Vietnam Shiprepair’s Overhauling Process

Our streamlined process ensures top performance:

-

Inspection: Assess engine components for wear, corrosion, or damage. Additionally, this identifies all issues.

-

Disassembly: Carefully dismantle the engine to identify faulty parts. Furthermore, this ensures thorough analysis.

-

Repair/Replacement: Fix or replace components, ensuring proper alignment and function. Consequently, performance is restored.

-

Testing: Rigorous pressure and performance tests confirm compliance with IACS, IMO, and maker standards. Therefore, safety is guaranteed.

Choose Vietnam Shiprepair for reliable, efficient main engine overhauling that keeps your vessel at its best.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

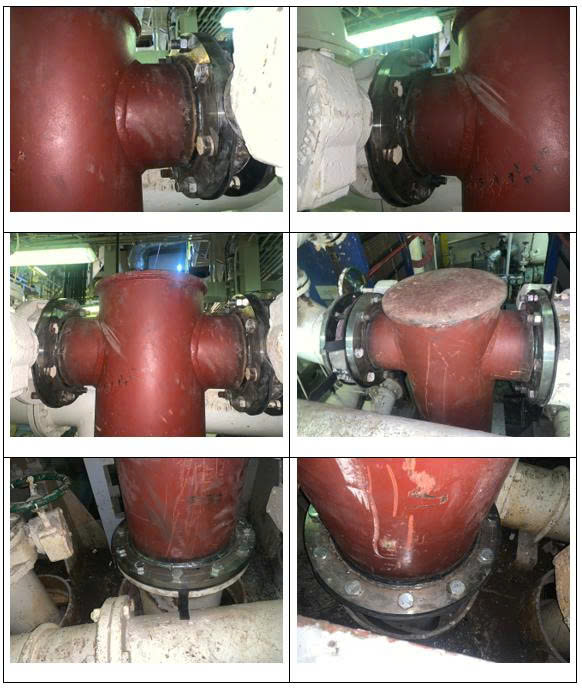

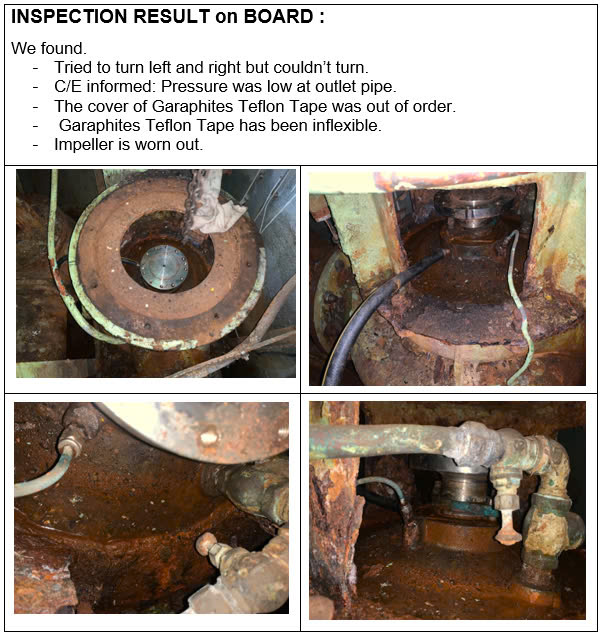

Sea Water Pump Repairs at Cam Pha Anchorage

Sea Water Pump Repairs at Cam Pha Anchorage – Efficient Solutions with VIETNAMSHIPREPAIR

Is your vessel’s sea water pump malfunctioning while anchored at Cam Pha Anchorage? VIETNAMSHIPREPAIR provides expert Sea Water Pump Repairs to restore cooling and operational efficiency, ensuring your vessel remains functional. We offer these services at Cam Pha Anchorage, as well as at Ho Chi Minh Port and Anchorage, Hai Phong Port, and Phu My Port – Vung Tau Anchorage, with the capability to serve vessels across Vietnam. Our repairs comply with International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) standards, ensuring safety and reliability. Trust VIETNAMSHIPREPAIR—the best in Vietnam—for your sea water pump repairs!

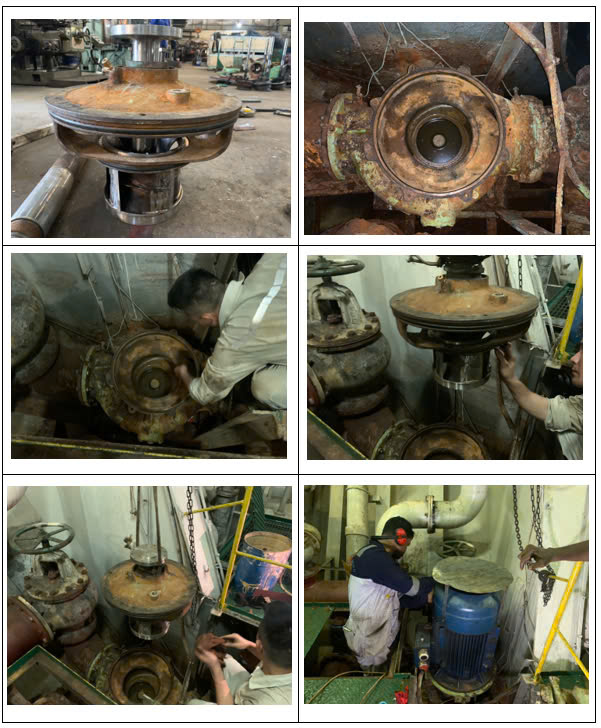

Damaged sea water pump before our expert repairs at Cam Pha Anchorage.

Advantages of Repairing Sea Water Pumps Over Replacement

Sea water pumps are vital for cooling a vessel’s engine and other systems, but wear from corrosion or mechanical failure can impair their performance. Opting for Sea Water Pump Repairs instead of replacement offers significant benefits:

-

Cost Efficiency: Repairing a pump is often 60-80% less expensive than buying a new one, saving you substantial costs while maintaining functionality.

-

Quick Restoration: Repairs can be completed faster than sourcing a new pump, minimizing downtime during critical operations.

-

Preserve Existing Design: Repairing keeps the pump’s original configuration, avoiding compatibility issues with your vessel’s systems.

-

Sustainability Benefits: Repairing reduces the need for new manufacturing, supporting eco-friendly practices on the water.

With VIETNAMSHIPREPAIR, your sea water pump will be restored effectively and economically.

Benefits of Timely Repairs During Cargo Operations

A faulty sea water pump can lead to overheating or system failures, causing delays or stoppages during cargo handling. Our Sea Water Pump Repairs provide timely solutions to keep your vessel operational:

-

Prevent Operational Delays: Swift repairs at Cam Pha Anchorage avoid schedule disruptions, ensuring cargo operations continue smoothly.

-

Avoid Unexpected Stoppages: Timely interventions prevent engine overheating, keeping loading and unloading on track.

-

Reduce Financial Losses: Addressing issues promptly helps avoid additional costs from port fees or penalties due to downtime.

-

Maintain Delivery Schedules: Keeping your vessel operational ensures timely cargo deliveries, preserving client satisfaction.

VIETNAMSHIPREPAIR’s rapid response keeps your operations running without interruption.

Safety Precautions During Sea Water Pump Repairs

Repairing sea water pumps involves handling heavy machinery and potentially hazardous conditions, requiring strict safety measures. VIETNAMSHIPREPAIR prioritizes safety with these precautions:

-

Equipment Isolation: We isolate the pump and related systems to prevent accidental activation during repairs.

-

Personal Protection: Our team uses personal protective equipment (PPE) to shield against water exposure and mechanical hazards.

-

Ventilation and Drainage: We ensure proper ventilation and manage water drainage to avoid slippery surfaces or electrical risks.

-

Post-Repair Testing: The pump is tested for leaks and performance to ensure safe operation after repairs.

Our dedication to safety ensures that Sea Water Pump Repairs are conducted without risks to your vessel or crew.

Cost Savings Through a Trusted Repair Services Provider

Choosing the right provider for Sea Water Pump Repairs can lead to significant cost savings. Substandard repairs can result in recurring failures, increasing downtime and expenses. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Minimized Downtime: Our Sea Water Pump Repairs reduce operational delays, saving you money at anchorages like Cam Pha Anchorage.

-

Durable Fixes: We use high-quality parts and techniques, ensuring long-lasting repairs that prevent future issues.

-

Preventive Cost Reduction: Thorough repairs lower the risk of major pump failures, reducing long-term maintenance costs.

With VIETNAMSHIPREPAIR, you get reliable repairs that protect your budget and vessel.

Compliance with IACS, NKK, and IMO Standards

The International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) set strict standards for vessel systems under IACS Unified Requirements (UR F), NKK rules, and IMO’s SOLAS (Safety of Life at Sea) regulations. Our Sea Water Pump Repairs ensure your pump meets these standards by restoring its efficiency and safety. VIETNAMSHIPREPAIR provides detailed reports for inspections, helping you avoid penalties or detentions. Explore maritime safety standards on the IMO website.

Sea water pump repairs in progress on a vessel.

VIETNAMSHIPREPAIR’s Expert Sea Water Pump Repair Process

At VIETNAMSHIPREPAIR, we follow a precise process for Sea Water Pump Services:

-

Inspection: We assess the pump for corrosion, seal damage, or impeller issues.

-

Disassembly: The pump is carefully disassembled, and faulty components are identified for repair or replacement.

-

Repair: Damaged parts are fixed or replaced, ensuring proper alignment and sealing.

-

Testing: The pump is tested under pressure to confirm compliance with IACS, NKK, and IMO standards.

This process ensures your sea water pump is fully operational and safe.

Fully repaired sea water pump after our expert services.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of Sea Water Pump Services, with over 20 years of experience. We offer services at Cam Pha Anchorage, Ho Chi Minh Port and Anchorage, Hai Phong Port, Phu My Port – Vung Tau Anchorage, and across Vietnam.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

Archives

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | 29 |

| 30 | 31 | |||||

Categories

- News (9)

- Project Updates (106)