- by Vietnam Ship Repair

- 0

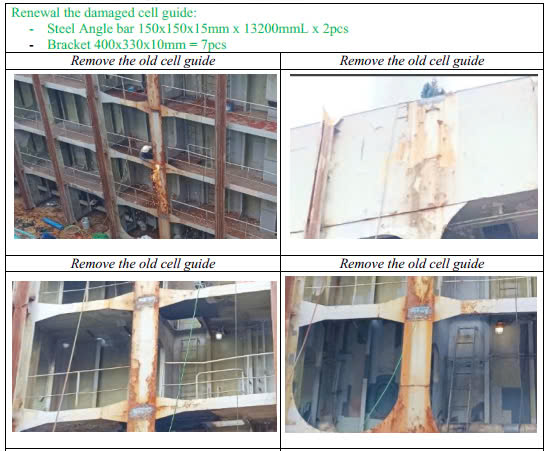

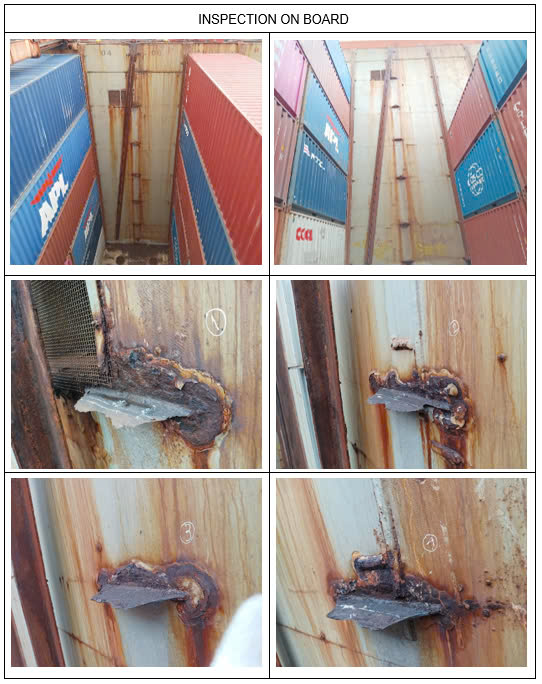

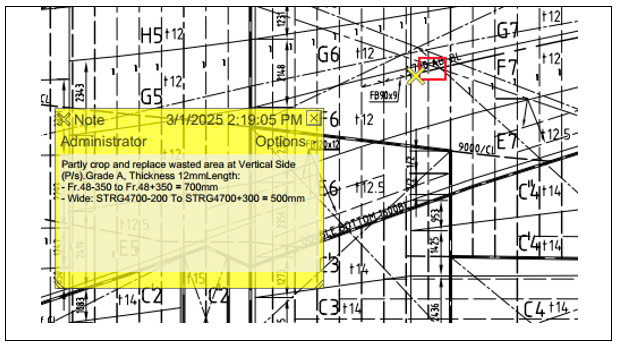

Steel Works at Da Nang Port – Cell Guide Repairs

Steel Works at Da Nang Port – Cell Guide Repairs with VIETNAMSHIPREPAIR

Are worn cell guides disrupting your container handling at Da Nang Port? VIETNAMSHIPREPAIR provides expert steel works, hot works services, and repair services to restore your cell guides, ensuring smooth and secure cargo operations. We deliver these services at Da Nang Port, as well as at Ho Chi Minh Port and Anchorage, Hai Phong Port, and Phu My Port – Vung Tau Anchorage, with the capability to serve vessels across Vietnam. Our repairs meet the standards of the International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO), guaranteeing safety and efficiency. Trust VIETNAMSHIPREPAIR—the best in Vietnam—for your cell guide repair needs!

Damaged cell guide before our expert steel works at Da Nang Port.

Why Replacing Worn Cell Guides is Essential for Cargo Handling

Cell guides are critical for aligning and stabilizing containers within the vessel’s holds during loading and unloading. When they become worn or damaged, they compromise cargo security. Our repair services address this by replacing faulty cell guides, offering key advantages:

-

Ensure Container Stability: Replacing worn cell guides through steel works prevents containers from shifting, ensuring safe storage during transit.

-

Minimize Cargo Damage: Functional cell guides reduce the risk of containers toppling or being misaligned, protecting valuable goods.

-

Enhance Loading Efficiency: Well-maintained cell guides speed up the loading and unloading process, keeping your schedule intact.

-

Boost Crew Safety: Secure cell guides lower the risk of accidents during cargo operations, safeguarding your team and equipment.

With VIETNAMSHIPREPAIR, your cell guides will support efficient and safe cargo management.

Benefits of Timely Cell Guide Repairs During Cargo Operations

A damaged cell guide can halt cargo operations, leading to costly delays or stoppages. Our repair services offer timely solutions to maintain your vessel’s workflow:

-

Prevent Operation Interruptions: Quick hot works services allow repairs to be completed while your vessel is at Da Nang Port, avoiding delays.

-

Avoid Unscheduled Downtime: Timely repairs ensure continuous loading and unloading, minimizing disruptions to your schedule.

-

Reduce Financial Losses: Addressing issues promptly helps avoid penalties or extra port charges due to halted operations.

-

Sustain Client Reliability: Keeping cargo operations on track ensures timely deliveries, maintaining strong client relationships.

VIETNAMSHIPREPAIR’s swift service keeps your cargo operations moving without interruption.

Safety Measures During Cell Guide Repairs

Repairing cell guides often involves hot works services, requiring strict safety protocols to protect the vessel and crew. VIETNAMSHIPREPAIR implements these measures:

-

Fire Hazard Control: Welding and cutting produce sparks, so we deploy fire watches and remove flammable materials from the area.

-

Adequate Ventilation: Hot works can release fumes, necessitating proper airflow to protect workers from inhalation risks.

-

Structural Stability: We ensure repairs maintain the vessel’s integrity, using precise welding techniques to avoid weak points.

-

Crew Protection Protocols: Our team uses personal protective equipment (PPE) and follows safety guidelines for confined space work.

Our dedication to safety ensures that steel works are conducted without compromising your vessel or crew.

Cost Savings Through a Trusted Repair Services Provider

Selecting the right provider for repair services can lead to significant cost savings. Subpar repairs can result in recurring issues, increasing downtime and expenses. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Reduced Downtime: Our hot works services minimize operational delays, saving you money at ports like Da Nang Port.

-

Durable Repairs: We use high-quality steel in our steel works, ensuring long-lasting results that prevent future problems.

-

Preventive Cost Management: Thorough repairs reduce the risk of major damage, lowering long-term maintenance costs.

With VIETNAMSHIPREPAIR, you get reliable repairs that protect your budget and vessel.

Compliance with IACS, NKK, and IMO Standards

The International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) establish strict standards for cargo handling systems under IACS Unified Requirements (UR C), NKK rules, and IMO’s SOLAS (Safety of Life at Sea) regulations. Our repair services ensure your cell guides meet these standards by restoring their functionality and safety. VIETNAMSHIPREPAIR provides detailed inspection reports, helping you avoid penalties or detentions. Explore maritime safety standards on the IMO website.

Steel works in progress to repair a cell guide on a container vessel.

VIETNAMSHIPREPAIR’s Expert Cell Guide Repair Process

At VIETNAMSHIPREPAIR, we follow a precise process for steel works and hot works services:

-

Evaluation: We inspect the cell guides for wear, damage, or misalignment.

-

Preparation: The work area is prepared, and safety measures are established for hot works.

-

Repair: Damaged cell guides are replaced or repaired using hot works services, ensuring proper alignment and strength.

-

Verification: The repaired cell guides are tested to confirm compliance with IACS, NKK, and IMO standards.

This process ensures your cell guides are fully restored and ready for cargo operations.

Newly repaired cell guide after our expert repair services.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of repair services, with over 20 years of experience. We offer services at Da Nang Port, Ho Chi Minh Port and Anchorage, Hai Phong Port, Phu My Port – Vung Tau Anchorage, and across Vietnam.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

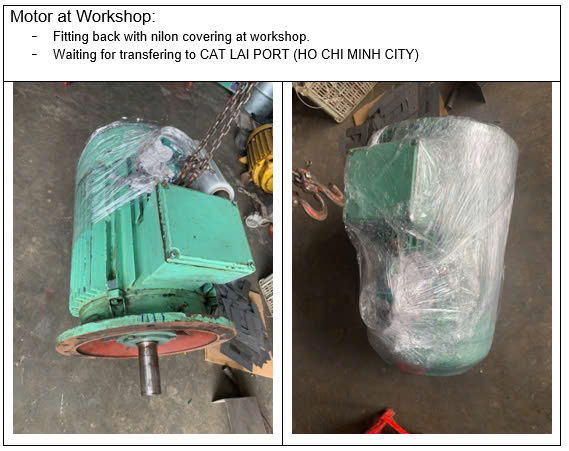

Motor Rewinding Services at Cat Lai Port – Ho Chi Minh

Motor Rewinding Services at Cat Lai Port – Ho Chi Minh – Cost-Effective Solutions with VIETNAMSHIPREPAIR

Is your container vessel’s motor failing while docked at Cat Lai Port – Ho Chi Minh? VIETNAMSHIPREPAIR offers expert motor rewinding services to restore your motor’s performance without the high cost of a replacement. We provide these services at Cat Lai Port – Ho Chi Minh, as well as at Ho Chi Minh Port and Anchorage, Hai Phong Port, and Phu My Port – Vung Tau Anchorage, with the capability to serve vessels across Vietnam. Our work complies with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards, ensuring reliability and safety. Trust VIETNAMSHIPREPAIR—the best in Vietnam—for your motor rewinding needs!

Caption: Damaged motor before our expert motor rewinding services at Cat Lai Port – Ho Chi Minh.

Economic Benefits of Rewinding a Motor Instead of Buying New

Motors on container vessels are critical for various operations, but they can wear out over time due to electrical faults or insulation breakdown. Choosing motor rewinding services over purchasing a new motor offers significant economic advantages:

-

Lower Costs: Rewinding a motor is often 50-70% cheaper than buying a new one, saving you significant expenses while restoring full functionality.

-

Reduced Downtime: Rewinding can be completed faster than sourcing and installing a new motor, keeping your vessel on schedule.

-

Preserve Existing Equipment: Rewinding maintains the motor’s original design and compatibility with your vessel’s systems, avoiding the need for costly modifications.

-

Sustainable Option: Rewinding reduces waste by reusing the motor’s core components, making it an environmentally friendly choice.

With VIETNAMSHIPREPAIR, you can achieve the same performance as a new motor at a fraction of the cost.

Key Considerations Before and After Motor Rewinding

Rewinding a motor requires careful preparation and follow-up to ensure optimal performance and safety. VIETNAMSHIPREPAIR follows strict protocols during motor rewinding services to address these considerations:

-

Before Rewinding: Inspect the motor for winding damage, core condition, and bearing wear, and ensure the work area is safe with proper electrical isolation.

-

During Rewinding: Use high-quality insulation materials and copper wire to rewind the motor, ensuring proper winding patterns and connections for optimal performance.

-

After Rewinding: Test the motor under load to verify electrical performance, check for vibration or overheating, and ensure proper alignment during reinstallation.

-

Documentation: Provide a detailed report of the rewinding process, including test results, for future reference and compliance checks.

Our thorough approach ensures your motor is restored to peak condition and ready for operation.

Cost Savings Through a Trusted Motor Rewinding Services Provider

Selecting the right provider for motor rewinding services can lead to substantial cost savings. Poor-quality rewinding can result in motor failure, increasing downtime and expenses. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Efficient Rewinding: Our motor rewinding services minimize downtime, reducing operational losses at ports like Cat Lai Port – Ho Chi Minh.

-

High-Quality Materials: We use premium insulation and copper wire, ensuring long-lasting performance and fewer future repairs.

-

Preventive Savings: Thorough rewinding prevents major motor failures, lowering long-term maintenance costs.

With VIETNAMSHIPREPAIR, you get reliable rewinding services that protect your budget and vessel.

Compliance with IACS and IMO Standards

The International Association of Classification Societies (IACS) and International Maritime Organization (IMO) set stringent standards for electrical equipment on vessels under IACS Unified Requirements (UR E) and IMO’s SOLAS (Safety of Life at Sea) regulations. Our motor rewinding services ensure your motor meets these standards by using compliant materials and techniques. VIETNAMSHIPREPAIR provides detailed reports for inspections, helping you avoid penalties or detentions. Explore maritime safety standards on the IMO website.

Caption: Motor rewinding services in progress on a container vessel’s motor.

VIETNAMSHIPREPAIR’s Expert Motor Rewinding Process

At VIETNAMSHIPREPAIR, we follow a precise process for motor rewinding services:

-

Inspection: We assess the motor for winding damage, core condition, and other issues to determine the scope of rewinding.

-

Rewinding: The old windings are removed, and new high-quality copper wire and insulation are installed with precision.

-

Testing: The motor is tested for electrical performance, insulation resistance, and balance to ensure reliability.

-

Reinstallation: The motor is reinstalled and tested under load to confirm compliance with IACS and IMO standards.

This process ensures your motor is fully restored and ready for operation.

Caption: Fully rewound motor after our expert motor rewinding services.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of motor rewinding services, with over 20 years of experience. We offer services at Cat Lai Port – Ho Chi Minh, Ho Chi Minh Port and Anchorage, Hai Phong Port, Phu My Port – Vung Tau Anchorage, and across Vietnam!

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

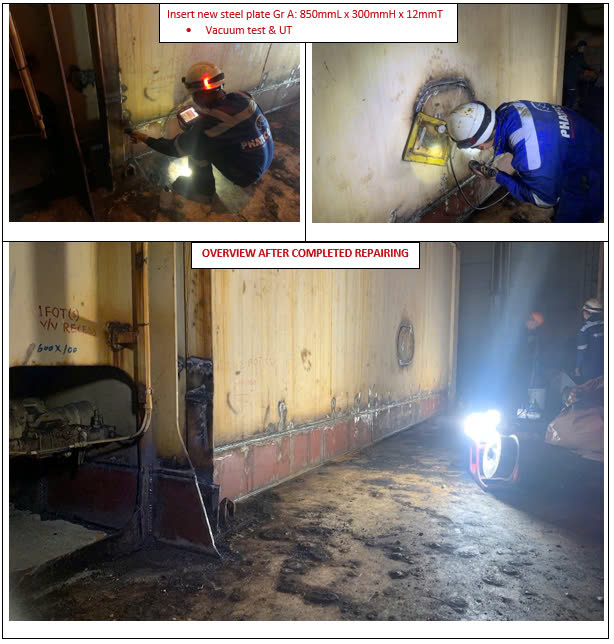

Steering Gears Repairs at Cam Pha Anchorage – Quang Ninh

Steering Gears Repairs at Cam Pha Anchorage – Quang Ninh – Hydraulic Cylinder Replacement with VIETNAMSHIPREPAIR

Is your container vessel’s steering gear hydraulic cylinder failing while anchored at Cam Pha Anchorage – Quang Ninh? VIETNAMSHIPREPAIR offers expert steering gears repairs, including hydraulic cylinder replacement, to ensure safe and efficient navigation. We provide these services at Cam Pha Anchorage – Quang Ninh, as well as at Ho Chi Minh Port and Anchorage, Hai Phong Port, and Phu My Port – Vung Tau Anchorage, with the capability to serve vessels across Vietnam. Our repairs comply with International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) standards, ensuring reliability and safety. Trust VIETNAMSHIPREPAIR—the best in Vietnam—for your steering gear solutions!

Caption: Worn hydraulic cylinder before our expert steering gears repairs at Cam Pha Anchorage – Quang Ninh.

How Hydraulic Cylinder Replacement Enhances Vessel Safety

The hydraulic cylinder is a vital component of your vessel’s steering gear, controlling rudder movement for precise navigation. Replacing a worn or damaged cylinder through steering gears repairs offers significant safety benefits:

-

Ensure Accurate Steering: A new cylinder restores precise rudder control, critical for avoiding hazards in busy waters.

-

Prevent Catastrophic Failures: Replacing a faulty cylinder reduces the risk of sudden steering loss, preventing accidents like groundings or collisions.

-

Maintain Vessel Stability: A reliable steering system ensures balanced handling, especially during challenging maneuvers or rough seas.

-

Protect Crew and Cargo: A safe steering mechanism safeguards your crew, cargo, and vessel during operations at all times.

With VIETNAMSHIPREPAIR, your vessel’s steering gear will support safe and efficient navigation.

Key Considerations Before and After Hydraulic Cylinder Replacement

Replacing a hydraulic cylinder requires meticulous preparation and follow-up to ensure optimal performance and safety. VIETNAMSHIPREPAIR follows strict protocols during steering gears repairs to address these considerations:

-

Before Replacement: Shut down the steering system, depressurize the hydraulic circuit, and inspect the cylinder for leaks or damage to confirm replacement is necessary.

-

During Replacement: Use precision tools to remove the old cylinder, install a new one, and ensure all hydraulic connections are tight and leak-free.

-

After Replacement: Refill the system with the correct hydraulic fluid, test the steering gear under load, and monitor for any irregularities during operation.

-

Documentation: Provide a detailed report of the replacement, including test results and compliance checks, for future reference.

Our thorough process ensures your steering gear is fully operational and safe post-repair.

Cost Savings Through a Trusted Steering Gears Repairs Provider

Selecting the right provider for steering gears repairs can lead to substantial cost savings. Substandard repairs can lead to recurring issues, increasing downtime and repair costs. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Minimized Downtime: Our steering gears repairs reduce operational delays, saving you money at anchorages like Cam Pha Anchorage – Quang Ninh.

-

Durable Components: We use high-quality, OEM-certified cylinders, ensuring long-lasting performance and fewer future repairs.

-

Preventive Cost Reduction: Thorough replacement prevents major steering gear failures, lowering long-term maintenance expenses.

With VIETNAMSHIPREPAIR, you get reliable repairs that protect your budget and vessel.

Compliance with IACS, NKK, and IMO Standards

The International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) set stringent standards for steering gear systems under IACS Unified Requirements (UR S), NKK rules, and IMO’s SOLAS (Safety of Life at Sea) regulations. Our steering gears repairs ensure your system meets these standards by installing compliant hydraulic cylinders. VIETNAMSHIPREPAIR provides detailed inspection reports, helping you avoid penalties or detentions. Explore maritime safety standards on the IMO website.

Caption: Steering gears repairs in progress, installing a new hydraulic cylinder on a container vessel.

VIETNAMSHIPREPAIR’s Expert Hydraulic Cylinder Replacement Process

At VIETNAMSHIPREPAIR, we follow a precise process for steering gears repairs:

-

Assessment: We evaluate the hydraulic cylinder for wear, leaks, or structural damage to determine the need for replacement.

-

Removal: The old cylinder is safely removed, and the system is prepared for the new installation.

-

Installation: A new cylinder is fitted, ensuring proper alignment and hydraulic integrity.

-

Testing: The steering gear is tested under various conditions to confirm compliance with IACS, NKK, and IMO standards.

This process ensures your steering gear is restored to full functionality and safety.

Caption: Newly installed hydraulic cylinder after our expert steering gears repairs.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of steering gears repairs, with over 20 years of experience. We offer services at Cam Pha Anchorage – Quang Ninh, Ho Chi Minh Port and Anchorage, Hai Phong Port, Phu My Port – Vung Tau Anchorage, and across Vietnam. Contact us today!

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Pilot Ladder Repairs at Go Gia Anchorage – Ho Chi Minh

Pilot Ladder Repairs at Go Gia Anchorage – Ho Chi Minh with VIETNAMSHIPREPAIR

Is your vessel’s pilot ladder in need of repair while stationed at Go Gia Anchorage – Ho Chi Minh? VIETNAMSHIPREPAIR specializes in pilot ladder repairs, ensuring safe and reliable boarding for pilots. We provide these services at Go Gia Anchorage – Ho Chi Minh, as well as at Hai Phong Port and Phu My Port, with the capability to serve vessels across Vietnam. Our repairs comply with International Association of Classification Societies (IACS), and International Maritime Organization (IMO) standards, ensuring safety and compliance. Trust VIETNAMSHIPREPAIR—the best in Vietnam—for your pilot ladder maintenance needs!

Damaged pilot ladder before our expert pilot ladder repairs at Go Gia Anchorage – Ho Chi Minh.

Why Repairing Pilot Ladders is Better Than Replacing Them

Pilot ladders are critical for safe pilot boarding, but wear and tear can compromise their functionality. Opting for pilot ladder repairs instead of a full replacement offers several advantages:

-

Cost-Effective Solution: Repairing a damaged ladder is significantly cheaper than purchasing a new one, saving you money without sacrificing safety.

-

Minimized Downtime: Repairs can be completed quickly, keeping your vessel operational and on schedule.

-

Preserve Existing Materials: Many ladder components can be restored, reducing waste and maintaining the ladder’s original design.

-

Ensure Safety Standards: Properly executed repairs ensure the ladder remains safe for use, meeting IMO and IACS requirements.

With VIETNAMSHIPREPAIR, you can restore your pilot ladder efficiently and affordably.

Key Considerations Before and After Pilot Ladder Repairs

Conducting pilot ladder repairs requires careful preparation and follow-up to ensure safety and compliance. VIETNAMSHIPREPAIR adheres to strict protocols to address these considerations:

-

Before Repairs: Inspect the ladder for damage, such as worn ropes, broken steps, or loose fittings, and ensure the work area is safe and free of hazards.

-

During Repairs: Use certified materials and techniques to replace or reinforce damaged components, ensuring the ladder meets regulatory standards.

-

After Repairs: Test the ladder under load to confirm its strength and stability, and verify that all fittings are secure before use.

-

Documentation: Provide a detailed report of the repairs, including materials used and test results, for future inspections.

Our thorough approach ensures your pilot ladder is safe and ready for use after repairs.

Cost Savings Through a Trusted Accommodation Repairs Provider

Choosing the right provider for pilot ladder repairs can lead to significant cost savings. Poor-quality repairs can result in recurring issues, increasing downtime and expenses. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Efficient Repairs: Our pilot ladder repairs minimize downtime, reducing operational losses at anchorages like Go Gia Anchorage – Ho Chi Minh.

-

Durable Fixes: We use high-quality materials to ensure long-lasting repairs, preventing the need for frequent maintenance.

-

Preventive Savings: Thorough repairs reduce the likelihood of ladder failure, avoiding costly replacements or penalties for non-compliance.

With VIETNAMSHIPREPAIR, you get reliable repairs that protect your budget and your vessel.

Compliance with IACS, NKK, and IMO Standards

The International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) set strict standards for pilot ladders under IACS Unified Requirements (UR A), NKK rules, and IMO’s SOLAS (Safety of Life at Sea) regulations, specifically Resolution A.1045(27) for pilot transfer arrangements. Our pilot ladder repairs ensure your ladder meets these standards by restoring its functionality and safety. VIETNAMSHIPREPAIR provides detailed reports for inspections, helping you avoid penalties or detentions. Explore maritime safety standards on the IMO website.

Pilot ladder repairs in progress on a vessel.

VIETNAMSHIPREPAIR’s Expert Pilot Ladder Repair Process

At VIETNAMSHIPREPAIR, we follow a precise process for Accommodation ladder repairs:

-

Inspection: We assess the ladder for damage, including worn ropes, broken steps, or loose fittings.

-

Repair: Damaged components are replaced or reinforced using certified materials, ensuring compliance with IMO standards.

-

Testing: The ladder is tested under load to confirm its strength and stability.

-

Reporting: A detailed report is provided, confirming compliance with IACS, NKK, and IMO standards.

This process ensures your pilot ladder is safe and compliant for use.

Fully restored pilot ladder after our expert pilot ladder services.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of Pilot ladder repairs, with over 20 years of experience. We offer services at Go Gia Anchorage – Ho Chi Minh, Hai Phong Port, Phu My Port, and across Vietnam. Contact us today!

-

Accommodation ladder repairs at Cai Mep Port.

-

Pilot ladder repairs at Go Gia anchorage and HCM City Ports.

-

Accommodation repairs at Nha Trang Port and Anchorage.

-

Accommodation repairs at Quy Nhon Port and Anchorage.

-

Accommodation at Da Nang Port and Anchorage.

-

Accommodation at Son Duong Port and Anchorage.

-

Pilot ladder repairs at Nghi Son Port and Anchorage.

-

Accommodation at Nghe Tinh and Vissai Port and Anchorage.

-

Accommodation at Hai Phong Port and Anchorage.

-

Accommodation at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Turbo Charger Services at Da Nang Anchorage

Turbo Charger Services at Da Nang Anchorage – Optimize Your Engine with VIETNAMSHIPREPAIR

Is your vessel’s main engine turbocharger performing at its best while anchored at Da Nang Anchorage? VIETNAMSHIPREPAIR offers professional turbo charger services and turbo charger overhauling to ensure your engine runs efficiently and reliably. We provide these services at Da Nang Anchorage, as well as at Hai Phong Port and Phu My Port, with the capability to serve vessels across Vietnam. Our maintenance complies with International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) standards, ensuring safety and performance. Trust VIETNAMSHIPREPAIR—the best in Vietnam—for your turbocharger maintenance needs!

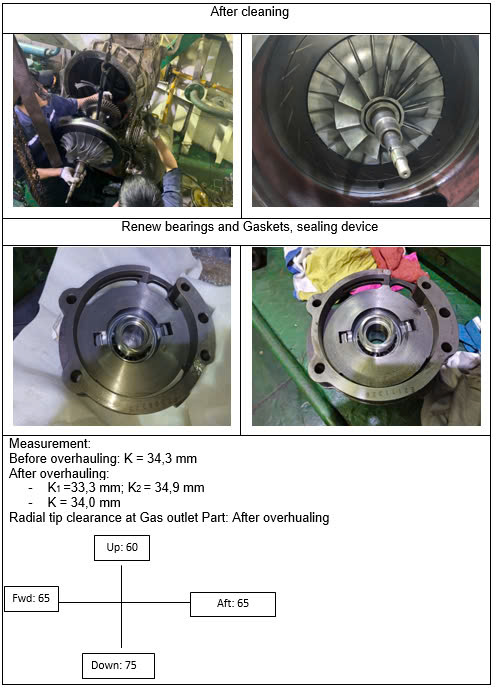

Turbocharger before our expert turbo charger services at Da Nang Anchorage.

Benefits of Periodic Turbo charger Services and Inspection

Regular inspection and maintenance through turbo charger services are essential for keeping your vessel’s main engine in top condition. Turbochargers boost engine power, but wear and tear can reduce their efficiency over time. Here’s why periodic maintenance matters:

-

Prevent Engine Downtime: Routine turbo charger overhauling identifies issues like bearing wear or blade damage before they cause engine failure.

-

Improve Fuel Efficiency: A well-maintained turbocharger ensures optimal air intake, reducing fuel consumption and operational costs.

-

Extend Turbocharger Lifespan: Regular maintenance prevents major damage, prolonging the life of your turbocharger.

-

Enhance Engine Performance: Consistent maintenance ensures your engine delivers maximum power, keeping your vessel on schedule.

With VIETNAMSHIPREPAIR, your turbocharger will perform reliably, supporting your vessel’s operations.

The Importance of Timely Spare Parts Replacement

Turbochargers have components like bearings, seals, and turbine blades that wear out over time and require replacement at specific intervals. Our turbo charger services include timely spare parts replacement, offering key benefits:

-

Prevent Major Failures: Replacing worn parts during turbo charger overhauling prevents catastrophic turbocharger breakdowns that could damage the engine.

-

Maintain Efficiency: New spare parts ensure the turbocharger operates at peak performance, supporting engine power and fuel efficiency.

-

Reduce Repair Costs: Timely replacements avoid the need for extensive repairs caused by neglected components.

-

Ensure Reliability: Fresh parts keep the turbocharger dependable, even during long voyages or at anchorages like Da Nang Anchorage.

VIETNAMSHIPREPAIR uses high-quality, OEM-approved spare parts to keep your turbocharger in optimal condition.

Key Considerations Before and After Turbo charger Overhauling

Performing turbo charger overhauling requires careful preparation and follow-up to ensure success and safety. VIETNAMSHIPREPAIR follows strict protocols to address these considerations:

-

Before Maintenance: Ensure the engine is shut down and cooled, isolate the turbocharger system, and verify that all safety measures are in place to protect workers.

-

During Maintenance: Use proper tools and techniques to avoid damaging components, and ensure all parts are cleaned and inspected thoroughly.

-

After Maintenance: Test the turbocharger at various loads to confirm performance, check for leaks or vibrations, and monitor engine parameters during operation.

-

Documentation: Provide a detailed report of the maintenance process, including replaced parts and test results, for future reference.

Our meticulous approach ensures your turbocharger is maintained safely and effectively.

Cost Savings Through a Trusted Turbo Charger Services Provider

Choosing the right provider for turbo charger services can lead to significant cost savings. Poor-quality maintenance can result in recurring issues, increasing downtime and expenses. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Efficient Maintenance: Our turbo charger overhauling minimizes downtime, reducing operational losses at anchorages like Da Nang Anchorage.

-

Long-Lasting Repairs: We use high-quality parts and techniques, ensuring durable results that prevent future issues.

-

Preventive Savings: Thorough maintenance reduces the likelihood of major engine damage, lowering long-term maintenance costs.

With VIETNAMSHIPREPAIR, you get reliable services that protect your budget and your vessel.

Compliance with IACS, NKK, and IMO Standards

The International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) set strict standards for engine components under IACS Unified Requirements (UR M), NKK rules, and IMO’s SOLAS (Safety of Life at Sea) regulations. Our turbo charger services ensure your turbocharger meets these standards by restoring its functionality and reliability. VIETNAMSHIPREPAIR provides detailed reports for inspections, helping you avoid penalties or detentions. Explore maritime safety standards on the IMO website.

Turbo charger overhauling in progress on a vessel’s main engine.

VIETNAMSHIPREPAIR’s Expert Turbo Charger Services Process

At VIETNAMSHIPREPAIR, we follow a precise process for turbo charger overhauling:

-

Inspection: We assess the turbocharger for wear, damage, or performance issues.

-

Disassembly: The turbocharger is carefully disassembled, and components are cleaned and inspected.

-

Repair and Replacement: Worn parts are replaced, and the turbocharger is overhauled using turbo charger services.

-

Testing: The turbocharger is reassembled and tested to confirm compliance with IACS, NKK, and IMO standards.

This process ensures your turbocharger is fully restored and ready for operation.

Fully restored turbocharger after our expert turbo charger services.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of turbo charger services, with over 20 years of experience. We offer services at Da Nang Anchorage, Hai Phong Port, Phu My Port, and across Vietnam. Contact us today!

-

turbo charger overhauling at Cai Mep Port.

-

turbo charger services at Nha Trang Port and Anchorage.

-

turbo charger maintenance at Quy Nhon Port and Anchorage.

-

turbo charger overhauling at Da Nang Port and Anchorage.

-

turbo charger overhauling at Son Duong Port and Anchorage.

-

turbo charger maintenance at Nghi Son Port and Anchorage.

-

turbo charger overhauling at Nghe Tinh and Vissai Port and Anchorage.

-

turbo charger maintenance at Hai Phong Port and Anchorage.

-

turbo charger overhauling at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Cell guides repair for Container Ship at Ho Chi Minh Port

Cell guides repair at Ho Chi Minh Port with VIETNAMSHIPREPAIR

Are damaged container guide rails disrupting your cargo operations at Ho Chi Minh Port? VIETNAMSHIPREPAIR provides expert steel works, hot works services, and Cell guides repair to restore your guide rails, ensuring smooth and safe cargo handling. We offer these services at Ho Chi Minh Port, as well as at Hai Phong Port and Quy Nhon Port, with the capability to serve vessels across Vietnam. Our repairs comply with International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) standards, keeping your operations safe and efficient. Trust VIETNAMSHIPREPAIR—the best in Vietnam—for your guide rail repairs!

Caption: Damaged container guide rail before Cell guides repair at Ho Chi Minh Port.

Why Replacing Faulty Cell guides is Essential for Cargo Operations

Container guide rails are critical for aligning and securing containers during loading and unloading. When they become damaged or misaligned, they can no longer ensure safe cargo handling. Our repair services address this issue by replacing faulty guide rails, offering key benefits:

-

Ensure Proper Alignment: Replacing damaged rails through steel works ensures containers are securely positioned, preventing shifting during transit.

-

Reduce Cargo Damage: Functional guide rails minimize the risk of containers slipping or falling, protecting valuable cargo.

-

Improve Operational Efficiency: Properly aligned rails speed up loading and unloading, keeping your vessel on schedule.

-

Enhance Safety: Secure containers reduce the risk of accidents during cargo operations, protecting your crew and equipment.

With VIETNAMSHIPREPAIR, your guide rails will be restored to ensure seamless cargo handling.

The Importance of Timely Cell guides repair During Cargo Operations

A damaged guide rail can halt or delay cargo operations, leading to costly downtime. Our Cell guides repair provide timely solutions to keep your vessel operational:

-

Prevent Operational Delays: Quick Cell guides ensure repairs are completed while your vessel is at Ho Chi Minh Port, avoiding schedule disruptions.

-

Avoid Cargo Handling Stoppages: Timely repairs prevent the need to stop loading or unloading, keeping your operations on track.

-

Minimize Financial Losses: By addressing issues promptly, we help you avoid penalties or additional port fees due to delays.

-

Maintain Client Satisfaction: Keeping your cargo operations on schedule ensures timely deliveries, maintaining trust with your clients.

VIETNAMSHIPREPAIR’s rapid response keeps your vessel moving without interruption.

Safety Considerations for Cell Guides Repai

Repairing container guide rails often involves Cell guides repair, which require careful safety measures to protect the vessel and crew. VIETNAMSHIPREPAIR follows strict protocols to ensure safety:

-

Fire Prevention: Welding and cutting can produce sparks, so we implement fire watches and ensure flammable materials are removed from the work area.

-

Ventilation: Hot works can generate fumes, requiring proper ventilation to protect workers from harmful gases.

-

Structural Integrity: We ensure repairs do not compromise the vessel’s structural strength, using precise welding techniques.

-

Crew Safety: Our team uses personal protective equipment (PPE) and follows confined space entry protocols to safeguard workers during repairs.

Our commitment to safety ensures that steel works are performed without risks to your vessel or crew.

Cost Savings Through a Trusted Cell guides repair Provider

Choosing the right provider for Cell guides repair can save you significant costs. Poor-quality repairs can lead to recurring issues, increasing downtime and expenses. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Efficient Repairs: Our hot works services minimize downtime, reducing operational losses at ports like Ho Chi Minh Port.

-

Durable Solutions: We use high-quality materials in our steel works, ensuring long-lasting repairs that prevent future issues.

-

Preventive Savings: Thorough repairs reduce the likelihood of major damage, lowering long-term maintenance costs.

With VIETNAMSHIPREPAIR, you get reliable repairs that protect your budget and your vessel.

Compliance with IACS, NKK, and IMO Standards

The International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) set strict standards for cargo handling equipment under IACS Unified Requirements (UR C), NKK rules, and IMO’s SOLAS (Safety of Life at Sea) regulations. Our repair services ensure your guide rails meet these standards by restoring their functionality and safety. VIETNAMSHIPREPAIR provides detailed reports for inspections, helping you avoid penalties or detentions. Explore maritime safety standards on the IMO website.

Caption: Cell guides repair in progress to repair a container guide rail on a vessel.

VIETNAMSHIPREPAIR’s Expert Repair Process

At VIETNAMSHIPREPAIR, we follow a precise process for steel works and hot works services:

-

Inspection: We assess the condition of the guide rails to identify damage or misalignment.

-

Preparation: The area is prepared, and safety measures are implemented for hot works.

-

Repair: Damaged rails are replaced or repaired using hot works services, ensuring proper alignment and strength.

-

Testing: The repaired rails are tested to confirm they meet IACS, NKK, and IMO standards.

This process ensures your guide rails are fully functional and safe for cargo operations.

Caption: Newly repaired Cell guides after our expert repair services.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of Cell guides repair, with over 20 years of experience. We offer services at Ho Chi Minh Port, Hai Phong Port, Quy Nhon Port, and across Vietnam. Contact us today first service!

-

Cell guides repair at Cai Mep Port.

-

Hot work services at Nha Trang Port and Anchorage.

-

Cell guides repair at Quy Nhon Port and Anchorage.

-

Cell guides repair at Da Nang Port and Anchorage.

-

Steel works at Son Duong Port and Anchorage.

-

Hot work services at Nghi Son Port and Anchorage.

-

Hot work services at Nghe Tinh and Vissai Port and Anchorage.

-

Hot work services at Hai Phong Port and Anchorage.

-

Hot work services at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

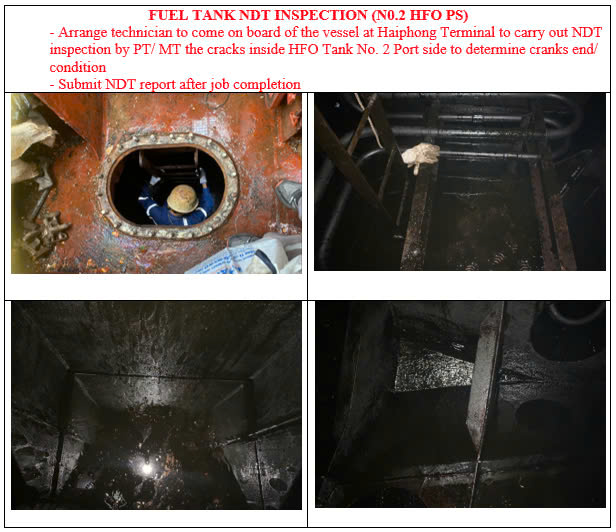

NDT Inspection for Container Ship at Nghi Son Port

NDT Services at Nghi Son Port – Fuel Tank Inspection with VIETNAMSHIPREPAIR

Are your fuel tanks in top condition while your vessel is docked at Son Duong Port? VIETNAMSHIPREPAIR provides expert NDT services and NDT inspection to ensure the integrity of your fuel tanks, detecting potential issues before they become major problems. We offer these services at Nghi Son Port, as well as at Ho Chi Minh Port, Hai Phong Port, and Quy Nhon Port, with the capability to serve vessels across Vietnam. Our inspections comply with International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) standards, ensuring safety and reliability. Trust VIETNAMSHIPREPAIR—the best in Vietnam—for your fuel tank inspections!

Fuel tank before our expert NDT services at Son Duong Port.

Benefits of Periodic NDT Inspection for Fuel Tanks

Regular NDT inspection of fuel tanks during dry-docking is crucial for maintaining your vessel’s operational integrity. Non-Destructive Testing (NDT) helps identify defects without damaging the tank, offering several key benefits:

-

Early Detection of Issues: Periodic NDT services reveal cracks, corrosion, or weld imperfections that could lead to leaks or failures.

-

Prevent Fuel Contamination: Identifying defects early ensures fuel remains uncontaminated, protecting your engines and systems.

-

Extend Tank Lifespan: Regular inspections allow for timely repairs, prolonging the life of your fuel tanks.

-

Minimize Downtime: Addressing issues early through NDT inspection prevents unexpected breakdowns, keeping your vessel on schedule.

With VIETNAMSHIPREPAIR, you can maintain your fuel tanks in optimal condition through routine NDT checks.

Identifying and Repairing Suspected Damage with NDT Inspection

Fuel tanks are prone to damage in hard-to-reach areas, making it challenging to detect issues without proper tools. Our NDT services are designed to inspect suspected areas of deterioration, enabling timely repairs:

-

Detect Hidden Defects: NDT inspection uses techniques like ultrasonic testing and magnetic particle inspection to identify cracks or corrosion in welds and tank walls.

-

Plan Effective Repairs: By pinpointing damaged areas, we help you develop a targeted repair plan, avoiding unnecessary work and costs.

-

Ensure Structural Integrity: Inspecting critical areas ensures the tank can withstand operational stresses, preventing leaks or ruptures.

-

Support Safe Operations: Addressing damage early keeps your vessel safe and operational, even at busy ports like Son Duong Port.

VIETNAMSHIPREPAIR’s NDT inspections ensure your fuel tanks are thoroughly assessed and ready for action.

Key Considerations for Fuel Tank NDT Inspection

Conducting an NDT inspection on fuel tanks requires careful planning and execution to ensure safety and accuracy. VIETNAMSHIPREPAIR follows strict protocols to address these considerations:

-

Tank Preparation: Tanks must be thoroughly cleaned and ventilated to remove fuel residues and ensure a safe working environment.

-

Certified Equipment: We use calibrated NDT tools to ensure precise and reliable results, meeting IACS, NKK, and IMO standards.

-

Trained Technicians: Our team is certified in NDT techniques, ensuring accurate defect detection and safe operations.

-

Confined Space Safety: Fuel tanks are confined spaces, requiring proper safety measures like gas monitoring and emergency protocols.

Our meticulous approach ensures a safe and effective NDT inspection process for your vessel.

Cost Savings Through a Trusted NDT Inspection Provider

Choosing the right provider for NDT services can lead to significant cost savings. Poor-quality inspections can miss critical defects, leading to costly repairs or downtime. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Accurate Results: Our thorough NDT inspection ensures precise defect detection, avoiding unnecessary repairs.

-

Minimized Downtime: We perform inspections efficiently at ports like Nghi Son Port, reducing operational delays.

-

Preventive Savings: Early detection of issues prevents major tank failures, saving you from expensive emergency repairs.

With VIETNAMSHIPREPAIR, you get reliable inspections that protect your budget and your vessel.

Compliance with IACS, NKK, and IMO Standards

The International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK), and International Maritime Organization (IMO) set strict standards for fuel tank integrity under IACS Unified Requirements (UR Z), NKK rules, and IMO’s SOLAS (Safety of Life at Sea) regulations. Our NDT services ensure your tanks meet these standards by identifying and addressing defects. VIETNAMSHIPREPAIR provides detailed reports for inspections, helping you avoid penalties or detentions. Explore maritime safety standards on the IMO website.

NDT inspection in progress on a fuel tank using ultrasonic testing.

VIETNAMSHIPREPAIR’s Expert NDT Inspection Process

At VIETNAMSHIPREPAIR, we follow a precise process for NDT inspection:

-

Preparation: The tank is cleaned, ventilated, and prepared for inspection.

-

Inspection: We perform NDT services using techniques like ultrasonic testing and magnetic particle inspection to detect defects.

-

Analysis: Results are analyzed to identify areas needing repair.

-

Reporting: A detailed report is provided, confirming compliance with IACS, NKK, and IMO standards.

This process ensures your fuel tanks are safe and compliant.

Detailed NDT inspection report after our expert NDT services.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of NDT services, with over 20 years of experience. We offer inspections at Nghi Son Port, Ho Chi Minh Port, Hai Phong Port, Quy Nhon Port, and across Vietnam. Contact us today!

-

NDT INSPECTION at Cai Mep Port.

-

NDT SERVICES at Nha Trang Port and Anchorage.

-

NDT SERVICES at Quy Nhon Port and Anchorage.

-

NDT SERVICES at Da Nang Port and Anchorage.

-

NDT INSPECTION at Son Duong Port and Anchorage.

-

NDT SERVICES at Nghe Tinh and Vissai Port and Anchorage.

-

NDT SERVICES at Hai Phong Port and Anchorage.

-

NDT SERVICES at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

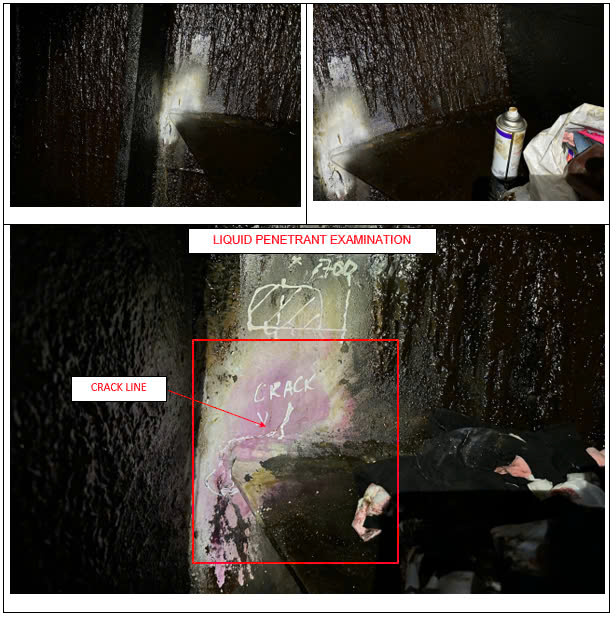

Steel Works for Bunker Vessel at Dung Quat Port – Replace Corroded Plates

Steel Works at Dung Quat Port – Replace Corroded Plates with VIETNAMSHIPREPAIR

Is corrosion compromising your vessel’s hull while docked at Dung Quat Port? VIETNAMSHIPREPAIR specializes in steel works and hot works to replace corroded plates, ensuring your ship remains safe and seaworthy. We offer these services at Dung Quat Port, as well as at Ho Chi Minh Port, Hai Phong Port, and Quy Nhon Port, with the capability to serve vessels across Vietnam. Our expert repairs comply with International Association of Classification Societies (IACS), Nippon Kaiji Kyokai (NKK) and International Maritime Organization (IMO) standards, keeping your vessel safe and efficient. Trust VIETNAMSHIPREPAIR—the best in Vietnam—for all your steel repair needs!

Corroded steel plate before our expert steel works at Dung Quat Port.

Why Replacing Corroded Steel Plates is Crucial

Corrosion is a common issue for vessels exposed to saltwater and harsh marine environments. Replacing corroded plates through steel works is essential for maintaining your ship’s integrity. Here’s why it matters:

-

Prevent Structural Damage: Corroded plates weaken the hull, increasing the risk of cracks or leaks that can compromise the vessel’s structure.

-

Avoid Water Ingress: Damaged plates can allow water to seep into compartments, leading to stability issues and potential flooding.

-

Extend Vessel Lifespan: Replacing corroded plates prevents further deterioration, prolonging the life of your ship.

-

Reduce Maintenance Costs: Addressing corrosion early through steel works prevents more extensive and expensive repairs down the line.

With VIETNAMSHIPREPAIR, you can protect your vessel from the damaging effects of corrosion.

How Steel Works Enhance Vessel Safety

A vessel with corroded plates poses significant safety risks during operation. Our Hot works services ensure safe navigation by:

-

Maintaining Hull Integrity: Replacing corroded plates restores the hull’s strength, ensuring it can withstand rough seas and heavy loads.

-

Preventing Accidents: A structurally sound hull reduces the risk of catastrophic failures, protecting your crew and cargo.

-

Ensuring Stability: Properly repaired plates maintain the vessel’s balance, preventing listing or capsizing during voyages.

-

Supporting Safe Operations: A seaworthy vessel can navigate confidently, even in challenging conditions at ports like Dung Quat Port.

VIETNAMSHIPREPAIR’s steel repairs keep your vessel safe and operational, no matter the journey.

The Dangers of Hot Works on a Vessel

Performing hot works, such as welding and cutting, to replace corroded plates on a vessel comes with inherent risks. VIETNAMSHIPREPAIR takes every precaution to ensure safety:

-

Fire Hazards: Welding sparks can ignite flammable materials, especially in confined spaces like fuel tanks or cargo holds.

-

Toxic Fumes: Hot works can release harmful gases, posing health risks to workers if proper ventilation is not ensured.

-

Structural Stress: Improper welding can weaken the hull, leading to cracks or further damage.

-

Crew Safety Risks: Without strict safety protocols, hot works can endanger the crew working nearby.

Our team follows strict safety guidelines, using certified equipment and trained technicians to mitigate these risks during hot works.

Save Costs by Choosing a Trusted Steel Works Provider

Selecting the right provider for steel works can lead to significant cost savings. A poorly executed repair can result in recurring issues, leading to costly downtime and further repairs. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Efficient Repairs: Our expert hot works minimize downtime, reducing operational losses at ports like Dung Quat Port.

-

High-Quality Materials: We use marine-grade steel to ensure long-lasting repairs, preventing future corrosion issues.

-

Preventive Approach: Thorough repairs reduce the likelihood of major hull damage, saving you money in the long run.

With VIETNAMSHIPREPAIR, you get reliable services that protect your budget and your vessel.

Compliance with IACS and IMO Regulations

The International Association of Classification Societies (IACS) and International Maritime Organization (IMO) set strict standards for vessel hull integrity under IACS Unified Requirements (UR S) and IMO’s SOLAS (Safety of Life at Sea) regulations. Our Hot works services ensure your vessel meets these standards by restoring the hull to its original strength. VIETNAMSHIPREPAIR provides detailed reports to support inspections, helping you avoid fines or detentions. Explore maritime safety standards on the IMO website.

Steel works in progress to replace corroded plates on a vessel.

VIETNAMSHIPREPAIR’s Expert Steel Works Process

At VIETNAMSHIPREPAIR, we follow a meticulous process for steel works and hot works:

-

Inspection: We assess the extent of corrosion and identify plates that need replacement.

-

Preparation: The area is cleaned, and safety measures are implemented for hot works.

-

Replacement: Corroded plates are removed, and new steel plates are welded into place using hot works.

-

Testing: The repaired area is tested for strength and water-tightness, ensuring compliance with IACS and IMO standards.

This process ensures your vessel’s hull is fully restored and safe for operation.

Newly replaced steel plate after our expert hot works service.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of Hot works services, with over 20 years of experience. We offer services at Dung Quat Port, Ho Chi Minh Port, Hai Phong Port, Quy Nhon Port, and across Vietnam. Contact us today!

-

Steel work at Cai Mep Port.

-

Hot work services at Nha Trang Port and Anchorage.

-

Hot work services at Quy Nhon Port and Anchorage.

-

Hot work services at Da Nang Port and Anchorage.

-

Hot work services at Son Duong Port and Anchorage.

-

Hot work services at Nghi Son Port and Anchorage.

-

Hot work services at Nghe Tinh and Vissai Port and Anchorage.

-

Hot work services at Hai Phong Port and Anchorage.

-

Hot work services at Cai Lan Port and Anchorage.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

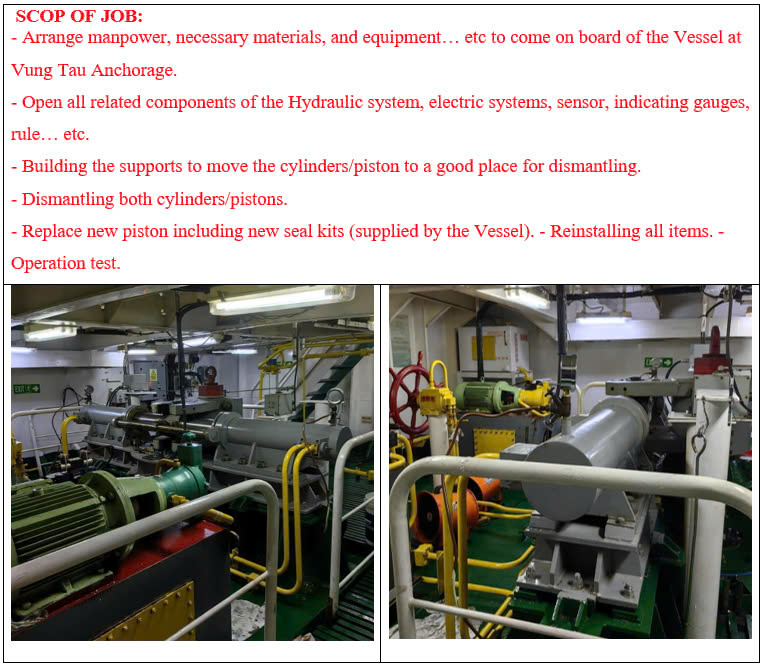

Steering Gears Overhauling for Tanker Vessel at Da Nang Port

– Ensure Safe Navigation with VIETNAMSHIPREPAIR

Is your vessel’s steering gear system reliable enough to navigate safely while docked at Da Nang Port? VIETNAMSHIPREPAIR offers expert steering gears overhauling and steering gears maintenance services to ensure your ship’s navigation system operates flawlessly. We provide these services at Da Nang Port, as well as at Ho Chi Minh Port, Hai Phong Port, and Quy Nhon Port, with the capability to serve vessels across Vietnam. Our work ensures compliance with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) regulations, keeping your vessel safe and efficient. Trust VIETNAMSHIPREPAIR—the best in Vietnam—to maintain your steering gears!

Caption: Steering gear system before our expert steering gears overhauling at Da Nang Port.

The Importance of Periodic Steering Gears Maintenance

Regular steering gears maintenance is essential for keeping your vessel’s navigation system in top condition. Steering gears control the ship’s direction, and any failure can lead to dangerous situations at sea. Here’s why periodic maintenance matters:

-

Prevent System Failures: Routine steering gears overhauling identifies issues like hydraulic leaks or worn components before they cause a breakdown.

-

Extend Equipment Lifespan: Proper maintenance reduces wear and tear, ensuring your steering gears last longer and perform reliably.

-

Reduce Downtime: Regular checks minimize the risk of unexpected failures, keeping your vessel on schedule at ports like Da Nang Port.

-

Cost-Effective Operations: Early detection of problems through maintenance prevents major repairs, saving you money in the long run.

With VIETNAMSHIPREPAIR, you can keep your steering gears in optimal condition and avoid costly disruptions.

How Steering Gears Maintenance Enhances Vessel Safety

A well-maintained steering gear system is critical for the safe operation of your vessel. Faulty steering gears can lead to loss of control, posing risks to your crew, cargo, and the ship itself. Our steering gears maintenance services ensure safety by:

-

Ensuring Precise Navigation: Regular steering gears overhauling guarantees accurate steering response, helping you navigate safely through busy waters.

-

Preventing Accidents: A reliable steering system reduces the risk of collisions or grounding, protecting your vessel and crew.

-

Maintaining Stability: Properly maintained gears ensure smooth handling, even in rough seas, enhancing overall vessel stability.

-

Supporting Emergency Maneuvers: A functional steering system allows for quick and effective maneuvers in critical situations.

VIETNAMSHIPREPAIR’s maintenance services keep your vessel safe and operational, no matter the conditions.

Save Costs by Choosing a Trusted Maintenance Provider

Selecting the right provider for steering gears maintenance can lead to significant cost savings. A subpar service can result in recurring issues, leading to expensive repairs or replacements. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Efficient Repairs: Our expert steering gears overhauling minimizes downtime, reducing operational losses at ports like Da Nang Port.

-

Affordable Maintenance: Regular maintenance is more cost-effective than emergency repairs or full system replacements.

-

Long-Term Savings: High-quality repairs prevent future breakdowns, lowering your overall maintenance costs.

With VIETNAMSHIPREPAIR, you get reliable services that protect your budget and your vessel.

Compliance with IACS and IMO Regulations

The International Association of Classification Societies (IACS) and International Maritime Organization (IMO) set strict standards for vessel navigation systems under IACS Unified Requirements (UR S) and IMO’s SOLAS (Safety of Life at Sea) regulations. Our steering gears overhauling ensures your system meets these standards by verifying its functionality and reliability. VIETNAMSHIPREPAIR provides detailed reports to support inspections, helping you avoid fines or detentions. Explore maritime safety standards on the IMO website.

Caption: Steering gears during our steering gears maintenance process at our workshop.

VIETNAMSHIPREPAIR’s Expert Maintenance Process

At VIETNAMSHIPREPAIR, we follow a thorough process for steering gears maintenance:

-

Inspection: We assess the steering gear system for issues like leaks, wear, or hydraulic failures.

-

Disassembly: The system is disassembled to examine each component in detail.

-

Overhauling: We perform steering gears overhauling, replacing worn parts and restoring functionality.

-

Testing: The system is tested to ensure it meets IACS and IMO standards for safety and performance.

This process ensures your steering gears are ready for safe navigation.

Caption: Fully restored steering gear after our expert steering gears overhauling service.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of steering gears maintenance, with over 20 years of experience. We offer services at Da Nang Port, Ho Chi Minh Port, Hai Phong Port, Quy Nhon Port, and across Vietnam.

-

steering gears overhauling at Cai Mep Port.

-

steering gears maintenance at Nha Trang Port and Anchorage.

-

steering gears maintenance at Quy Nhon Port and Anchorage.

-

steering gears overhauling at Da Nang Port and Anchorage.

-

steering gears overhauling at Son Duong Port and Anchorage.

-

steering gears maintenance at Nghi Son Port and Anchorage.

-

steering gears overhauling at Nghe Tinh and Vissai Port and Anchorage.

-

steering gears maintenance at Hai Phong Port and Anchorage.

-

steering gears overhauling at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

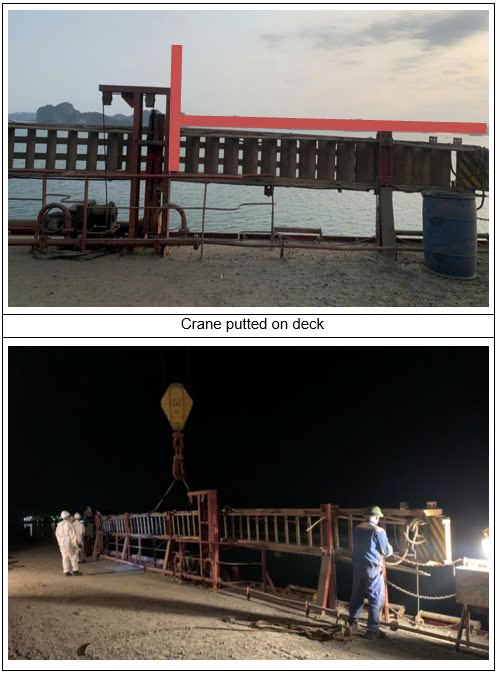

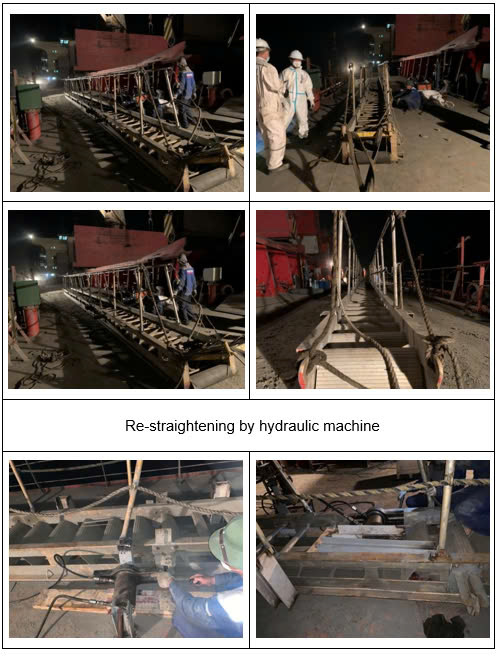

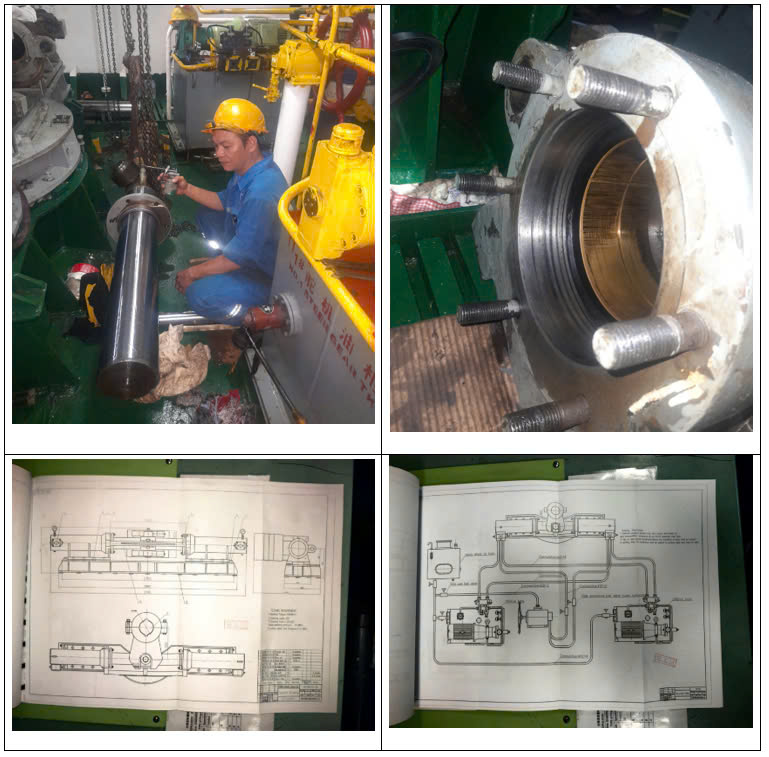

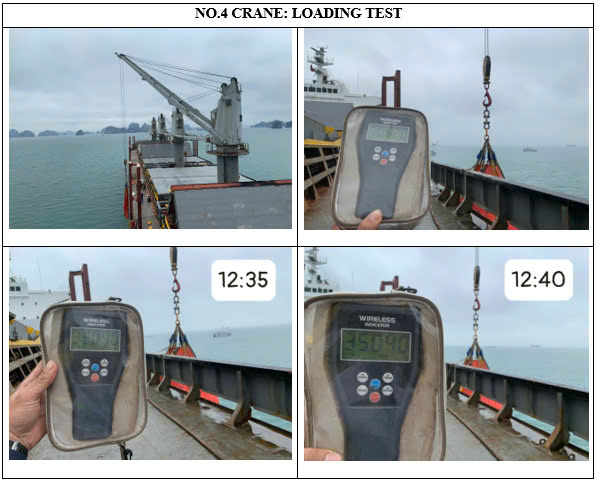

Load Test Cargo Cranes Bunker Vessel at Quy Nhon Port

Load Test Cargo Cranes at Quy Nhon Port – Ensure Safety with VIETNAMSHIPREPAIR

Are your cargo cranes at Quy Nhon Port ready to handle a 30-ton load safely? VIETNAMSHIPREPAIR offers expert load test Cargo Cranes and load test Crane services to ensure your equipment operates reliably and meets safety standards. We conduct tests at Quy Nhon Port, as well as at Phu My Port, Ho Chi Minh Port, Hai Phong Port, and Da Nang Port, with the ability to serve vessels across Vietnam. Our certified methods keep your cranes compliant with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) regulations. Trust VIETNAMSHIPREPAIR—the best in Vietnam—to safeguard your operations!

Cargo crane before our expert load test Cargo Cranes at Quy Nhon Port.

Why Periodic Load Testing of Cargo Cranes is Essential

Regularly conducting a load test Crane is vital for maintaining the safety and efficiency of your vessel’s cargo cranes. Cranes that handle heavy loads, such as 30 tons, are subject to wear and stress over time, which can lead to unexpected failures. Here’s why periodic testing matters:

-

Prevent Equipment Failure: A load test Cargo Cranes identifies weak points in the crane’s structure or mechanism before they cause a breakdown.

-

Ensure Operational Efficiency: Tested cranes perform reliably, reducing delays during loading and unloading at ports like Quy Nhon Port.

-

Enhance Safety: Regular testing minimizes the risk of accidents, protecting your crew and cargo from potential hazards.

-

Extend Crane Lifespan: Early detection of issues through testing allows for timely repairs, prolonging the crane’s operational life.

With VIETNAMSHIPREPAIR, you can ensure your cranes are always ready for the toughest tasks.

The Safety of Load Testing with Certified Water Bags

When performing a load test Crane, safety is our top priority. VIETNAMSHIPREPAIR uses certified water bags—a proven and safe method for load testing cargo cranes. Here’s why this approach is ideal:

-

Controlled Load Application: Water bags allow us to gradually apply a 30-ton load, ensuring the crane is tested safely without sudden stress.

-

Certified Accuracy: Our water bags come with internationally recognized certificates, guaranteeing precise and reliable results.

-

Minimized Risk: Unlike traditional methods with solid weights, water bags reduce the risk of damage to the crane or vessel during testing.

-

Environmental Safety: Water bags are eco-friendly, with no risk of hazardous spills or waste.

This safe and efficient method ensures your load test Cargo Cranes is conducted without compromising safety or accuracy.

Save Costs by Choosing a Trusted Load Testing Provider

Selecting the right provider for your load test Crane can lead to significant cost savings. A poorly executed test can result in inaccurate results, leading to unnecessary repairs or even crane failure. VIETNAMSHIPREPAIR offers cost-effective solutions:

-

Accurate Testing: Our certified methods ensure precise results, avoiding costly re-tests or repairs.

-

Minimized Downtime: We perform tests efficiently at ports across Vietnam, including Quy Nhon Port, reducing operational delays.

-

Preventive Maintenance: A thorough load test Cargo Cranes helps identify issues early, saving you from expensive crane replacements.

With VIETNAMSHIPREPAIR, you get reliable testing that saves you money in the long run.

Compliance with IACS and IMO Regulations

The International Association of Classification Societies (IACS) and International Maritime Organization (IMO) set strict standards for cargo crane safety under IACS Unified Requirements (UR M) and IMO’s SOLAS (Safety of Life at Sea) regulations. A load test Crane ensures your equipment meets these standards by verifying its ability to handle a 30-ton load safely. VIETNAMSHIPREPAIR provides detailed test reports to support inspections, helping you avoid fines or detentions. Explore maritime safety standards on the IMO website.

Load test Cargo Cranes in progress using certified water bags at our testing site.

VIETNAMSHIPREPAIR’s Expert Load Testing Cargo Cranes Process

At VIETNAMSHIPREPAIR, we follow a meticulous process for load test Cargo Cranes:

-

Inspection: We assess the crane’s condition to ensure it’s ready for testing.

-

Setup: Certified water bags are filled to simulate a 30-ton load.

-

Testing: We conduct the load test Crane, monitoring the crane’s performance under load.

-

Reporting: A detailed report is provided, confirming compliance with IACS and IMO standards.

This process ensures your crane is safe and reliable for heavy-duty operations.

Certified water bags and Load Cell used during our load test Crane service.

Nationwide Service with VIETNAMSHIPREPAIR

VIETNAMSHIPREPAIR is Vietnam’s leading provider of load test Cargo Cranes, with over 20 years of experience. We offer services at Phu My Port, Ho Chi Minh Port, Hai Phong Port, Da Nang Port, and across Vietnam.

-

load test Crane at Cai Mep Port.

-

load test Crane at Nha Trang Port and Anchorage.

-

load test Crane at Quy Nhon Port and Anchorage.

-

load test Crane at Da Nang Port and Anchorage.

-

load test Crane at Son Duong Port and Anchorage.

-

load test Crane at Nghi Son Port and Anchorage.

-

load test Crane at Nghe Tinh and Vissai Port and Anchorage.

-

load test Crane at Hai Phong Port and Anchorage.

-

load test Crane at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.