- by Vietnam Ship Repair

- 0

Recondition Valve Spindles & Seats at Van Phong Anchorage

Recondition Valve Spindles & Seats at Van Phong Anchorage – Expert Services by Vietnam Shiprepair

Are your vessel’s valve spindles and seats deteriorating at Van Phong Anchorage? Vietnam Shiprepair Co. offers expert Main Engine Services, VietNam Workshop and Marine Service, ensuring optimal engine performance. On August 22, 2025, we successfully reconditioned valve spindles and seats for a bulk carrier at Van Phong Anchorage without disrupting engine operations. Moreover, our services extend to all anchorages and ports across Vietnam, including Da Nang Port, Nghi Son Port, Vung Tau, and Ho Chi Minh City. Our repairs comply with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Therefore, trust Vietnam Shiprepair for dependable marine solutions!

A Vietnam Shiprepair technician inspecting worn valve spindles at Van Phong Anchorage.

A Vietnam Shiprepair technician inspecting worn valve spindles at Van Phong Anchorage.

Importance of Main Engine Systems and Regular Maintenance

The main engine system, including valve spindles and seats, is the heart of any vessel, driving propulsion and power generation at Van Phong Anchorage. These components regulate fuel and air intake, ensuring efficient combustion. Neglecting regular maintenance can lead to engine failure, costly downtime, and non-compliance with IACS and IMO safety standards. Timely Main Engine Services and reconditioning through VietNam Workshop are essential to sustain performance, protect the engine, and ensure crew safety.

Basic Steps for Reconditioning Valve Spindles & Seats

Vietnam Shiprepair recently reconditioned valve spindles and seats at Van Phong Anchorage due to performance issues. Here are the key steps to address insufficient engine efficiency:

-

Inspection: Technicians assess spindles and seats for wear, corrosion, and misalignment using precision tools.

-

Disassembly: Components are carefully removed from the engine for workshop processing.

-

Reconditioning at Workshop: At our VietNam Workshop, damaged parts are machined, ground, and polished to restore original specifications, adhering to IACS/IMO standards.

-

Reassembly: Reconditioned spindles and seats are reinstalled with exact alignment.

-

Testing: Pressure and performance tests verify engine integrity.

-

Final Coating: Anti-corrosion treatment is applied to enhance longevity.

This process ensured optimal engine function, but timely execution is crucial to avoid delays.

Importance of Minimizing Downtime During Reconditioning

Reconditioning valve spindles and seats in the shortest time possible without affecting engine schedules is vital at Van Phong Anchorage. Delays disrupt operations, leading to financial losses and missed deadlines. Vietnam Shiprepair prioritizes rapid Main Engine Services, completing reconditioning efficiently with workshop support. Moreover, quick service minimizes exposure to operational risks, ensuring IACS and IMO compliance while keeping the vessel running.

Vietnam Shiprepair’s Compliance with Main Engine Services

A reputable repair unit must adhere to rigorous machining processes and IACS-certified technicians. Vietnam Shiprepair meets these criteria, using advanced equipment at our VietNam Workshop to ensure component durability. Our technicians are IACS-certified, guaranteeing expertise recognized by classification societies. This compliance with IACS and IMO standards ensures reconditioned valve spindles and seats withstand marine stresses, enhancing engine reliability.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Service, including Main Engine Services, across Vietnam:

-

Van Phong Anchorage: Ideal for efficient repairs, as demonstrated recently.

-

Da Nang Port: A key hub for quick Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Nghi Son Port, Vung Tau, and all ports and anchorages.

-

Mobile Operations: Our team brings tools and workshop support directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

Vietnam Shiprepair team reconditioning valve seats at their VietNam Workshop.

Vietnam Shiprepair team reconditioning valve seats at their VietNam Workshop.

Benefits of Choosing Vietnam Shiprepair for Main Engine Services

Selecting Vietnam Shiprepair for Main Engine Services ensures peace of mind. Our Marine Service saves time with rapid reconditioning, preserving engine schedules at Van Phong Anchorage. Additionally, reconditioning valve spindles and seats reduces costs compared to full engine overhauls, optimizing your budget. Moreover, our IACS-certified technicians deliver trusted results, enhancing vessel performance and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IACS and IMO compliance, providing detailed reports for inspections. Contact us for efficient Vietnam Shiprepair!

Reconditioned valve components enhancing engine performance.

Reconditioned valve components enhancing engine performance.

Vietnam Shiprepair’s Commitment to Excellence

Our reconditioning process guarantees quality. We inspect components for damage. Then, we disassemble and recondition at our VietNam Workshop with precision. After that, we test for safety. Finally, we ensure IACS/IMO compliance. Choose Vietnam Shiprepair for reliable Main Engine Services.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Anchor Chains Replacement at Da Nang Anchorage

Anchor Chains Replacement at Da Nang Anchorage

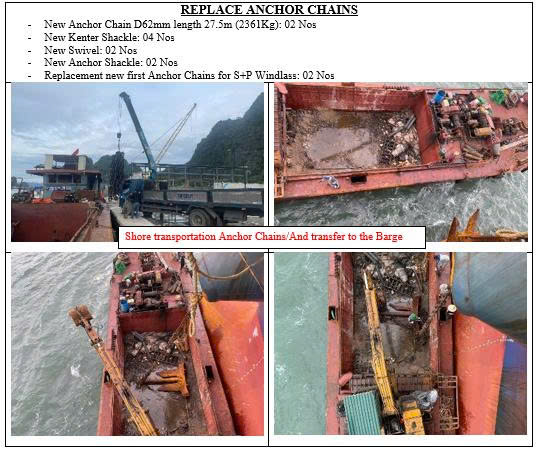

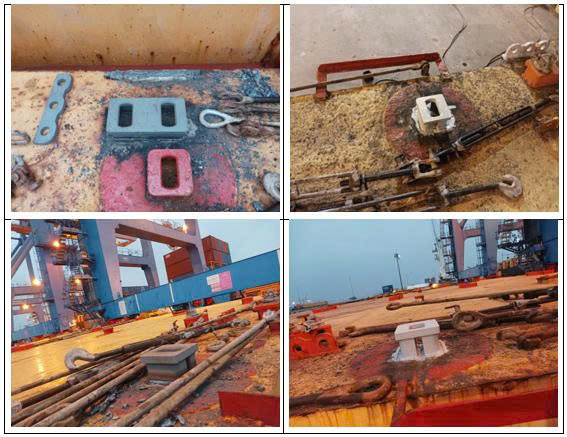

Are your vessel’s anchor chains worn out at Da Nang Anchorage? Vietnam Shiprepair Co. provides expert Anchor Chains Replacement, VietNam Shiprepair, and Marine Service, ensuring safe mooring. On August 19, 2025, we successfully replaced anchor chains for a bulk carrier at Da Nang Anchorage without disrupting mooring schedules. Moreover, our services extend to all anchorages and ports across Vietnam, including Nghi Son Anchorage, Vung Tau, and Ho Chi Minh City. Our replacements comply with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Therefore, trust Vietnam Shiprepair for dependable marine solutions!

Technician assessing anchor chain for replacement.

Technician assessing anchor chain for replacement.

Importance of Anchor Chains and Anchors for Vessels

Anchor chains and anchors are the foundation of vessel safety, securing ships at Da Nang Anchorage against wind, currents, and tides. These components absorb environmental forces, preventing drifting or grounding that could endanger crew, cargo, and the environment. Worn or damaged chains compromise stability and violate IACS and IMO safety standards. Vietnam Shiprepair’s Anchor Chains Replacement and Marine Service restore these critical elements, ensuring compliance and operational reliability.

Basic Steps for Anchor Chains and Anchor Replacement

Vietnam Shiprepair recently replaced anchor chains at Da Nang Anchorage due to safety concerns. Here are the key steps to address insufficient mooring safety:

-

Utilizing Barge Support: A specialized barge is deployed to assist in lifting and positioning the new anchor chain, ensuring stability during the process.

-

Employing Skilled Technicians: Experienced welders and engineers handle the replacement, minimizing errors and ensuring precision.

-

Following Provided Drawings: Replacement is executed according to detailed blueprints to avoid costly mistakes, adhering to IACS/IMO standards.

-

Installation: New chains and anchors are installed with secure by lead and alignment.

-

Testing: Tension and load tests verify the strength and integrity of the replacement.

-

Coating: Anti-corrosion coating is applied to enhance durability.

This process ensured safe mooring, but timely execution is crucial to avoid delays.

Importance of Minimizing Downtime During Replacement

Replacing anchor chains and anchors in the shortest time possible without affecting mooring schedules is vital at Da Nang Anchorage. Delays disrupt operations, leading to financial losses and missed deadlines. Vietnam Shiprepair prioritizes rapid Anchor Chains Replacement, completing tasks efficiently with barge support and skilled teams. Moreover, quick service minimizes exposure to weather risks, ensuring IACS and IMO compliance while keeping the vessel operational.

Vietnam Shiprepair’s Compliance with Anchor Chains Replacements

A reputable repair unit must adhere to rigorous welding processes and IACS-certified welders. Vietnam Shiprepair meets these criteria, using advanced techniques to ensure weld durability. Our welders are IACS-certified, guaranteeing expertise recognized by classification societies. This compliance with IACS and IMO standards ensures replaced chains withstand marine stresses, enhancing safety during mooring.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Service, including Anchor Chains Replacements, across Vietnam:

-

Da Nang Anchorage: Ideal for efficient repairs, as demonstrated recently.

-

Nghi Son Anchorage: A key hub for quick Vietnam Shiprepair solutions.

-

Nationwide Reach: We serve Vung Tau, Ho Chi Minh City, and all ports and anchorages.

-

Mobile Operations: Our team brings tools and barges directly to your vessel.

-

Rapid Response: Fast deployment minimizes downtime.

Explore our services at Vietnam Shiprepair Services.

Team replacing anchor chain with barge support.

Team replacing anchor chain with barge support.

Benefits of Choosing Vietnam Shiprepair for Anchor Chains Replacements

Selecting Vietnam Shiprepair for Anchor Chains Replacement ensures peace of mind. Our Marine Service saves time with rapid replacements, preserving mooring schedules at Da Nang Anchorage. Additionally, our cost-effective approach reduces expenses compared to full chain overhauls, optimizing your budget. Moreover, our IACS-certified technicians deliver trusted results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IACS and IMO compliance, providing detailed reports for inspections. Contact us for efficient Vietnam Shiprepair!

Replaced anchor chain securing vessel.

Replaced anchor chain securing vessel.

Vietnam Shiprepair’s Commitment to Excellence

Our replacement process guarantees quality. We inspect chains for damage. Then, we remove and replace with precision using barge support and skilled technicians. After that, we test for safety. Finally, we ensure IACS/IMO compliance. Choose Vietnam Shiprepair for reliable Anchor Chains Replacement.

Contact Vietnam Shiprepair

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

-

Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

-

Mobile/WhatsApp/WeChat: +84 869 677 769.

-

Email: contact@vietnamshiprepair.net.

-

Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

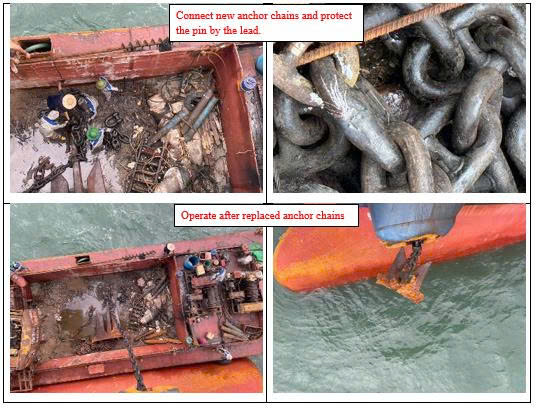

Motor Rewinding at Nghi Son Anchorage

Motor Rewinding at Nghi Son Anchorage

August 08, 2025, and your vessel is anchored at Nghi Son Anchorage. The motor powering the engine room ventilation system has failed, risking overheating and endangering crew safety. Vietnam ShipRepair delivers exceptional Motor Rewinding, VietNam ShipRepair, and Marine Service, ensuring reliability at Nghi Son Anchorage and across Vietnam’s key ports, including Da Nang, Vung Tau, and Ho Chi Minh City. Our expertise keeps your vessel safe, efficient, and compliant.

Technician assessing motor for rewinding.

Technician assessing motor for rewinding.

The Essential Role of Engine Room Ventilation and Motors

Engine room ventilation systems, driven by robust electric motors, are the backbone of bulk carriers, regulating air quality and preventing machinery overheating. At Nghi Son Anchorage, where vessels endure intense heat and humidity, a malfunctioning motor can cause engine damage, compromise crew comfort, and violate International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards. Prompt Motor Rewinding and Marine Service are vital to sustain performance, protect equipment, and ensure safety at sea. Learn more about IMO standards here.

The Expert Motor Rewinding Process: From Dismantling to Reinstallation

Vietnam ShipRepair executes Motor Rewinding and Marine Service with unmatched precision:

-

Onboard Dismantling: Skilled technicians remove the motor from the vessel at Nghi Son Anchorage, conducting a detailed inspection to identify damage.

-

Workshop Rewinding: The motor is transported to our advanced facility in Hai Phong or Ho Chi Minh City, where damaged coils are replaced with premium copper wire, insulated to marine standards, and aligned with IMO and IACS guidelines.

-

Onboard Reinstallation: After rigorous testing, the rewound motor is reinstalled and optimized, restoring ventilation efficiency with minimal disruption.

This process ensures top performance across Vietnam’s maritime network. Discover our full range of services at Vietnam ShipRepair Services.

Team rewinding motor in specialized workshop.

Team rewinding motor in specialized workshop.

Advantages of Timely Motor Rewinding and Marine Service

Choosing Motor Rewinding, VietNam ShipRepair, and Marine Service unlocks significant benefits:

-

Superior Ventilation Performance: Rewound motors deliver consistent airflow, preventing overheating during operations at Da Nang or Vung Tau.

-

Minimized Operational Delays: Swift repairs keep your vessel on schedule, avoiding costly downtime.

-

Significant Cost Savings: Proactive maintenance reduces the need for expensive replacements, enhancing budget efficiency.

-

Guaranteed Compliance: Strict adherence to IMO and IACS standards ensures your vessel meets global safety requirements.

Vietnam ShipRepair’s dedication to excellence drives efficiency, savings, and reliability. Explore IACS guidelines here.

Rewound motor enhancing vessel ventilation.

Rewound motor enhancing vessel ventilation.

Why Vietnam ShipRepair Stands Out as Your Trusted Partner

Our state-of-the-art workshops and skilled teams in Hai Phong and Ho Chi Minh City uphold IMO and IACS compliance, delivering unmatched quality. Ship operators nationwide trust us for our rapid response and proven track record. Learn more about our commitment at Vietnam ShipRepair Services.

Don’t let a faulty motor jeopardize your ventilation system. Partner with Vietnam ShipRepair for outstanding Motor Rewinding and Marine Service at Nghi Son Anchorage and beyond. Contact us, to schedule your service and experience unparalleled reliability and peace of mind.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

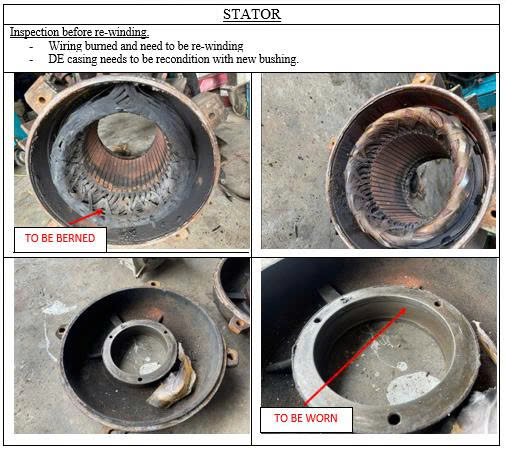

Steel/Hot Works at Quy Nhon Port

Steel/Hot Works at Quy Nhon Port – Expert Lashing Eyes and Container Sockets Replacement by Vietnam Shiprepair

Are your container ship’s lashing eyes and container sockets worn out at Quy Nhon Port? Vietnam Shiprepair Co. provides expert Steel/Hot Works, including rapid replacement of these vital components, to ensure safe cargo handling. July 08, 2025, we successfully replaced lashing eyes and container sockets for a container ship at Quy Nhon Port without disrupting loading schedules. Moreover, our Marine Services and VietNam ShipRepair solutions extend to all ports and anchorages across Vietnam, including Danang Port, Nghi Son Port, Vung Tau, and beyond. Our repairs comply with International Association of Classification Societies (IACS) and International Maritime Organization (IMO) standards—learn more at IACS Standards. Therefore, trust Vietnam Shiprepair for reliable marine solutions!

Vietnam Shiprepair team performing steel/hot works on lashing eyes at Quy Nhon Port.

Vietnam Shiprepair team performing steel/hot works on lashing eyes at Quy Nhon Port.

Importance of Lashing Eyes and Container Sockets for Container Ships

Lashing eyes and container sockets are critical for container ships, securing cargo during transit at Quy Nhon Port. Lashing eyes provide anchor points for tie-downs, while container sockets lock containers in place, preventing movement that could destabilize the vessel. Damaged or worn components risk cargo loss, structural damage, or capsizing, endangering crew and schedules. Moreover, they violate IACS and IMO safety standards. Vietnam Shiprepair’s Steel/Hot Works restores these elements, ensuring compliance and operational safety.

Basic Steps for Replacing Lashing Eyes and Container Sockets

Vietnam Shiprepair recently replaced lashing eyes and container sockets at Quy Nhon Port due to safety concerns. Here are the key steps to address insufficient cargo handling safety:

- Inspection: We assessed components for cracks, wear, and misalignment.

- Removal: Cut out old lashing eyes and sockets using precise hot work techniques.

- Preparation: Cleaned and prepped the deck, ensuring a strong weld base.

- Installation: Welded new lashing eyes and sockets, adhering to IACS/IMO standards.

- Testing: Conducted load and stability tests to verify secure cargo handling.

- Coating: Applied anti-corrosion coating to prevent future degradation.

This process ensured safe operations, but timely execution is crucial to avoid delays.

Importance of Minimizing Downtime During Replacement

Replacing lashing eyes and container sockets in the shortest time possible without affecting loading schedules is paramount at Quy Nhon Port. Delays disrupt cargo operations, leading to financial losses and missed deadlines. Vietnam Shiprepair prioritizes rapid Steel/Hot Works, completing replacements efficiently to maintain workflow. Moreover, quick service minimizes exposure to weather risks, ensuring IACS and IMO compliance while keeping the vessel operational, a key advantage for busy ports.

Vietnam Shiprepair’s Compliance with Steel/Hot Works

A reputable repair unit must adhere to two critical standards: a rigorous welding process and IACS-certified welders. Vietnam Shiprepair meets these criteria, using advanced hot work techniques to ensure weld strength and durability. Our welders are IACS-certified, guaranteeing expertise recognized by classification societies. This compliance with IACS and IMO standards ensures the replaced components withstand marine stresses, enhancing safety during cargo operations.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Services, including Steel/Hot Works, across Vietnam:

- Quy Nhon Port: Ideal for efficient repairs, as shown recently.

- Danang Port: A key hub for quick VietNam ShipRepair solutions.

- Nationwide Reach: We serve Nghi Son Port, Vung Tau, and all ports and anchorages. Explore Services.

- Mobile Operations: Our team brings tools directly to your vessel.

- Rapid Response: Fast deployment minimizes downtime.

Vietnam Shiprepair team providing marine services at Quy Nhon Port.

Vietnam Shiprepair team providing marine services at Quy Nhon Port.

Benefits of Choosing Vietnam Shiprepair for Steel/Hot Works

Selecting Vietnam Shiprepair for Steel/Hot Works ensures peace of mind. Our Marine Services save time with rapid replacements, preserving loading schedules at Quy Nhon Port. Additionally, our cost-effective approach reduces expenses compared to extensive deck repairs, optimizing your budget. Moreover, our IACS-certified technicians deliver trusted results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IACS and IMO compliance, providing detailed reports for inspections. Contact us for efficient VietNam ShipRepair! Contact Us.

Replaced lashing eyes and container sockets by Vietnam Shiprepair at Quy Nhon Port.

Replaced lashing eyes and container sockets by Vietnam Shiprepair at Quy Nhon Port.

Vietnam Shiprepair’s Commitment to Excellence

Our repair process guarantees quality. We inspect components for damage. Then, we remove and replace with precision hot work. After that, we test for safety. Finally, we ensure IACS/IMO compliance. Choose Vietnam Shiprepair for reliable Steel/Hot Works.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

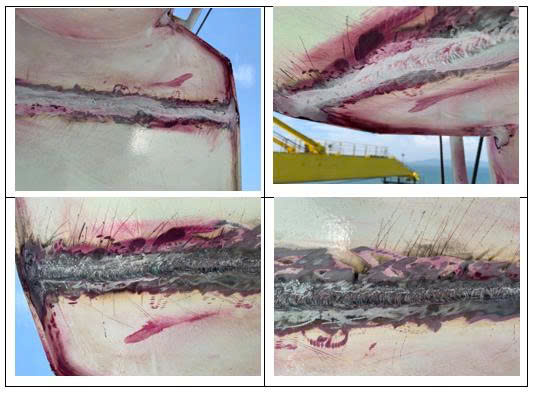

Hull Plate Replacement– Expert Steel Works at Phu My Port

Hull Plate Replacement– Expert Steel Works at Phu My Port by Vietnam Shiprepair

Is your bulk carrier’s hull compromised at Phu My Port due to damaged side plating? Vietnam Shiprepair Co. provides expert Steel Works, including hull plate replacement, to ensure watertightness and safety. July 2025, we successfully replaced a 3000 x 2000 x 14 mm side plate for a bulk carrier at Phu My Port. Moreover, our Marine Services and VietNam ShipRepair solutions extend to all ports and anchorages across Vietnam, including Danang Port, Nghi Son Port, Vung Tau, and beyond. Our repairs comply with International Association of Classification Societies (IACS) and Nippon Kaiji Kyokai (NKK) standards—learn more at IACS Standards. Therefore, trust Vietnam Shiprepair for reliable marine solutions!

Vietnam Shiprepair team replacing a hull plate at Phu My Port.

Vietnam Shiprepair team replacing a hull plate at Phu My Port.

Importance of Watertightness for Ship Hulls

Watertightness is critical for bulk carriers, preventing water ingress that threatens stability at Phu My Port. A compromised hull, especially on the side plating, can lead to flooding, endangering cargo, crew, and the vessel itself. Moreover, it violates IACS and NKK structural integrity standards, risking classification suspension. Vietnam Shiprepair’s Steel Works restores watertightness, ensuring compliance and operational safety in harsh marine environments.

Hull Plate Replacement: a 3000 x 2000 x 14 mm Side Plate

Vietnam Shiprepair recently replaced a damaged side plate measuring 3000 x 2000 x 14 mm on a bulk carrier at Phu My Port. This specific size ensures a precise fit, addressing corrosion or impact damage to maintain hull strength. The new plate, crafted from high-grade steel, enhances durability and aligns with IACS and NKK design specifications. This replacement is crucial to prevent leaks and maintain the vessel’s seaworthiness.

Basic Steps for Hull Plate Replacement

Vietnam Shiprepair executed the hull plate replacement at Phu My Port with these key steps:

- Inspection: We assessed the damaged area, identifying crack extent and corrosion.

- Removal: Cut out the old 3000 x 2000 x 14 mm plate using precision tools.

- Preparation: Cleaned and prepped the hull surface, ensuring a strong weld base.

- Installation: Positioned and welded the new plate, adhering to IACS/NKK welding standards.

- Grinding and Coating: Ground welds smooth and applied anti-corrosion coating.

- Testing: Ultrasonic Testing and watertightness tests to verify compliance.

This process restored the hull’s integrity, meeting international safety requirements.

Vietnam Shiprepair’s Compliance with Welding Standards

A reputable repair unit must follow two critical standards: a rigorous welding process and NKK-certified welders. Vietnam Shiprepair meets these requirements, using advanced welding techniques to ensure joint strength and durability. Our welders are NKK-certified, guaranteeing expertise recognized by classification societies. This compliance with IACS and NKK standards ensures the repaired hull withstands marine stresses, enhancing safety and reliability.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Services, including Steel Works, across Vietnam:

- Phu My Port: Ideal for efficient repairs, as shown recently.

- Danang Port: A key hub for quick VietNam ShipRepair solutions.

- Nationwide Reach: We serve Nghi Son Port, Vung Tau, and all ports and anchorages. Explore Services.

- Mobile Operations: Our team brings tools directly to your vessel.

- Rapid Response: Fast deployment minimizes downtime.

Vietnam Shiprepair team providing marine services at Phu My Port.

Vietnam Shiprepair team providing marine services at Phu My Port.

Benefits of Choosing Vietnam Shiprepair for Steel Works

Selecting Vietnam Shiprepair for Steel Works ensures peace of mind. Our Marine Services save time with rapid repairs, avoiding delays at Phu My Port. Additionally, our cost-effective approach reduces expenses compared to extensive hull overhauls, optimizing your budget. Moreover, our NKK-certified technicians deliver trusted results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IACS and NKK compliance, providing detailed reports for inspections. Contact us for efficient VietNam ShipRepair! Contact Us.

Repaired hull with new 3000 x 2000 x 14 mm plate by Vietnam Shiprepair at Phu My Port.

Repaired hull with new 3000 x 2000 x 14 mm plate by Vietnam Shiprepair at Phu My Port.

Vietnam Shiprepair’s Commitment to Excellence

Our repair process guarantees quality. We inspect the hull for damage. Then, we remove and replace the plate with precision. After that, we test for watertightness. Finally, we ensure IACS/NKK compliance. Choose Vietnam Shiprepair for reliable Steel Works.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Steel Works at Da Nang Port

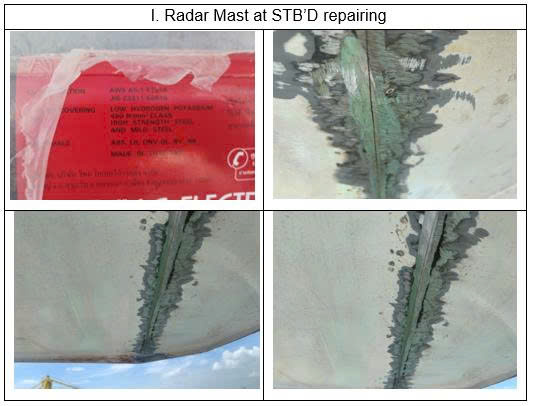

Steel Works at Da Nang Port – Expert Radar Mast Weld Repair by Vietnam Shiprepair

Is your container ship’s radar mast affected by cracked welds at Da Nang Port? Vietnam Shiprepair Co. provides expert Steel Works to restore structural integrity and safety. We successfully repaired a cracked weld on a radar mast for a container ship at Da Nang Port. Moreover, our Marine Services and VietNam ShipRepair solutions extend to all ports and anchorages across Vietnam, including Nghi Son Port, Vung Tau, and beyond. Our repairs comply with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards—learn more at IMO Standards. Therefore, trust Vietnam Shiprepair for reliable marine solutions!

Vietnam Shiprepair team performing steel works on a radar mast at Da Nang Port.

Vietnam Shiprepair team performing steel works on a radar mast at Da Nang Port.

Importance of Radar Systems for Maritime Operations

Radar systems, mounted on masts, are essential for container ships, enabling navigation and obstacle detection at Da Nang Port. They provide real-time data on weather, traffic, and hazards, ensuring safe passage in low-visibility conditions. A compromised radar mast, due to cracked welds, risks equipment failure, endangering crew and cargo. Moreover, it violates IMO and IACS structural safety standards. Vietnam Shiprepair’s Steel Works ensures the radar system remains operational, supporting maritime efficiency and safety.

Benefits of Timely Radar Mast Weld Repairs

Timely repair of cracked welds on a radar mast at Da Nang Port minimizes significant risks. It prevents mast collapse, which could damage radar equipment or injure crew during storms. Additionally, it reduces the chance of signal interference, avoiding navigation errors that lead to collisions or grounding. Moreover, prompt Steel Works mitigates corrosion spread, extending the mast’s lifespan and meeting IMO and IACS inspection requirements. Vietnam Shiprepair’s expertise ensures these risks are addressed, maintaining vessel reliability.

Basic Steps for Steel Works: Radar Mast Weld Repair

Vietnam Shiprepair recently repaired a cracked weld on a radar mast at Da Nang Port. Here are the key steps:

- Inspection: We identified crack locations and assessed structural damage using non-destructive testing.

- Preparation: Cleaned the area, removing rust and old weld material to ensure a strong bond.

- Welding: Applied high-strength steel welds, adhering to IMO/IACS standards for durability.

- Cooling and Grinding: Allowed welds to cool, then ground them smooth to eliminate stress points.

- Testing: Conducted visual and load tests to verify integrity and compliance.

This process restored the mast’s stability, meeting international safety norms.

Vietnam Shiprepair team providing marine services at Da Nang Port.

Vietnam Shiprepair team providing marine services at Da Nang Port.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Services, including Steel Works, across Vietnam:

- Da Nang Port: Ideal for efficient repairs, as shown recently.

- Nghi Son Port: A key hub for quick VietNam ShipRepair solutions.

- Nationwide Reach: We serve Vung Tau, and all ports and anchorages. Explore Services.

- Mobile Operations: Our team brings tools directly to your vessel.

- Rapid Response: Fast deployment minimizes downtime.

Vietnam Shiprepair team providing marine services at Da Nang Port

Vietnam Shiprepair team providing marine services at Da Nang Port

Benefits of Choosing Vietnam Shiprepair for Steel Works

Selecting Vietnam Shiprepair for Steel Works ensures peace of mind. Our Marine Services save time with rapid repairs, avoiding delays at Da Nang Port. Additionally, our cost-effective approach reduces expenses compared to full mast replacement, optimizing your budget. Moreover, our IACS-approved technicians deliver trusted results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IMO and IACS compliance, providing detailed reports for inspections. Contact us for efficient VietNam ShipRepair! Contact Us.

Repaired radar mast with new welds by Vietnam Shiprepair at Da Nang Port.

Repaired radar mast with new welds by Vietnam Shiprepair at Da Nang Port.

Vietnam Shiprepair’s Commitment to Excellence

Our repair process guarantees quality. We inspect the mast for cracks. Then, we prepare and weld with precision. After that, we test for safety. Finally, we ensure IMO/IACS compliance. Choose Vietnam Shiprepair for reliable Steel Works.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

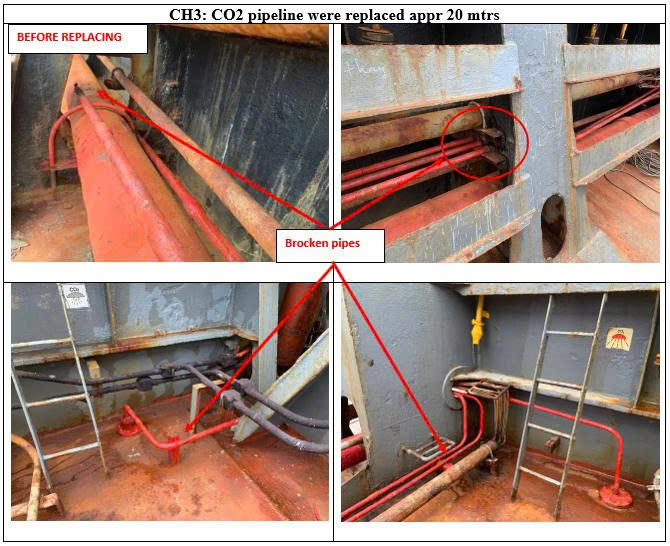

Hot Works at Cam Pha Anchorage – Expert CO2 Pipe Replacement

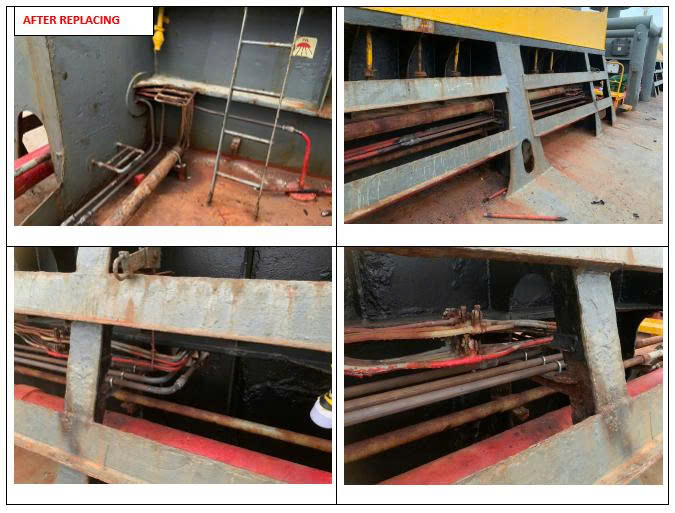

Hot Works at Cam Pha Anchorage – Expert CO2 Pipe Replacement by Vietnam Shiprepair

Is your bulk carrier’s CO2 piping system compromised at Cam Pha Anchorage? Vietnam Shiprepair Co. provides expert Hot Works, including CO2 pipe replacement, to enhance fire suppression safety. July 04, 2025, we successfully replaced CO2 pipes for a bulk carrier at Cam Pha Anchorage. Moreover, our Marine Services and VietNam ShipRepair solutions extend to all ports and anchorages across Vietnam, including Danang Port, Nghi Son Port, Vung Tau, and beyond. Our work complies with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards—learn more at IMO Standards. Therefore, trust Vietnam Shiprepair for reliable marine solutions!

Vietnam Shiprepair team replacing CO2 pipes at Cam Pha Anchorage

Vietnam Shiprepair team replacing CO2 pipes at Cam Pha Anchorage

Importance of CO2 Piping Systems for Maritime Operations

The CO2 piping system is vital for bulk carriers, delivering carbon dioxide to suppress fires at Cam Pha Anchorage. It protects the engine room, cargo holds, and crew quarters from fire and explosion risks, ensuring vessel safety during operations. A damaged or corroded pipe can fail to release CO2 effectively, endangering lives and cargo. Moreover, it violates IMO and IACS fire safety regulations. Vietnam Shiprepair’s Hot Works restores this critical system, maintaining compliance and operational integrity.

Significance of Regular CO2 Piping System Maintenance

Regular maintenance of the CO2 piping system is essential to prevent failures at Cam Pha Anchorage. Periodic inspections address corrosion, leaks, and blockages caused by salt and wear. Additionally, it ensures the system remains pressurized and ready for emergencies, meeting IMO and IACS safety standards. Moreover, timely Hot Works reduces the risk of fire-related incidents, avoiding costly repairs and downtime. Vietnam Shiprepair’s expertise keeps your CO2 system reliable and inspection-ready.

Basic Steps for Safe CO2 Pipe Replacement and Hot Works

Vietnam Shiprepair recently replaced CO2 pipes at Cam Pha Anchorage. Here are the key steps to ensure fire and explosion safety:

- Inspection: We checked pipes for corrosion, cracks, and pressure integrity.

- Isolation: Shut down the CO2 system and isolated the affected section safely.

- Removal: Cut out damaged pipes, ensuring no debris enters the system.

- Installation: Welded new steel pipes, adhering to IMO/IACS standards for material and thickness.

- Pressure Testing: Conducted hydrostatic tests to verify leak-proof performance.

- Reconnection: Reconnected the system and tested CO2 release for compliance.

This process ensured a safe, functional CO2 system, meeting international safety norms.

Vietnam Shiprepair team providing marine services at Cam Pha Anchorage.

Vietnam Shiprepair team providing marine services at Cam Pha Anchorage.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Services, including Hot Works, across Vietnam:

- Cam Pha Anchorage: Ideal for efficient repairs, as shown recently.

- Danang Port: A key hub for quick VietNam ShipRepair solutions.

- Nationwide Reach: We serve Nghi Son Port, Vung Tau, and all ports and anchorages. Explore Services.

- Mobile Operations: Our team brings tools directly to your vessel.

- Rapid Response: Fast deployment minimizes downtime.

Benefits of Choosing Vietnam Shiprepair for Hot Works

Selecting Vietnam Shiprepair for Hot Works ensures peace of mind. Our Marine Services save time with rapid repairs, avoiding delays at Cam Pha Anchorage. Additionally, our cost-effective approach reduces expenses compared to full system overhauls, optimizing your budget. Moreover, our IACS-approved technicians deliver trusted results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IMO and IACS compliance, providing detailed reports for inspections. Contact us for efficient VietNam ShipRepair! Contact Us.

Fully replaced CO2 piping system by Vietnam Shiprepair at Cam Pha Anchorage.

Fully replaced CO2 piping system by Vietnam Shiprepair at Cam Pha Anchorage.

Vietnam Shiprepair’s Commitment to Excellence

Our maintenance process guarantees quality. We inspect pipes for damage. Then, we isolate and replace with precision. After that, we test for safety. Finally, we ensure IMO/IACS compliance. Choose Vietnam Shiprepair for reliable Hot Works.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Sea Water Pump Repairing at Cam Pha Anchorage

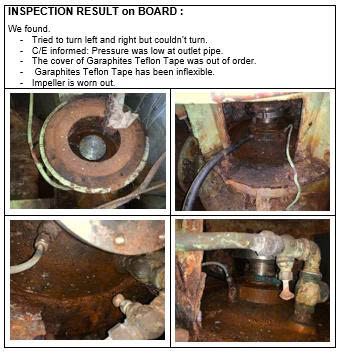

Sea Water Pump Repairing at Cam Pha Anchorage – Expert Solutions by Vietnam Shiprepair

Is your bulk carrier’s sea water pump failing at Cam Pha Anchorage due to a worn impeller? Vietnam Shiprepair Co. provides expert Sea Water Pump Repairing, including impeller replacement, to restore cooling efficiency. We successfully replaced an impeller for a bulk carrier at Cam Pha Anchorage. Moreover, our Marine Services and VietNam ShipRepair solutions extend to all ports and anchorages across Vietnam, including Danang Port, Nghi Son Port, Vung Tau, and beyond. Our work complies with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards—learn more at IMO Standards. Therefore, trust Vietnam Shiprepair for reliable marine services!

Vietnam Shiprepair team replacing an impeller on a sea water pump at Cam Pha Anchorage.

Vietnam Shiprepair team replacing an impeller on a sea water pump at Cam Pha Anchorage.

Importance of Sea Water Pumps for Maritime Operations

Sea water pumps are essential for bulk carriers, circulating seawater to cool engines and machinery at Cam Pha Anchorage. They prevent overheating, ensuring the main engine and auxiliary systems operate efficiently. A malfunctioning pump, especially with a damaged impeller, can lead to engine failure, risking crew safety and cargo schedules. Moreover, it impacts compliance with IMO and IACS cooling efficiency standards. Vietnam Shiprepair’s Sea Water Pump Repairing restores performance, maintaining vessel reliability in harsh marine conditions.

Significance of Regular Sea Water Pump Maintenance

Regular maintenance of sea water pumps is critical to avoid breakdowns at Cam Pha Anchorage. Periodic checks prevent impeller wear, corrosion, and blockages caused by salt and debris. Additionally, it enhances cooling efficiency, reducing fuel consumption and engine stress. Moreover, timely Sea Water Pump Repairing meets IMO and IACS safety regulations, ensuring inspection readiness and avoiding penalties. Vietnam Shiprepair’s expertise ensures your pump remains functional, minimizing unexpected downtime.

Basic Steps for Sea Water Pump Maintenance and Impeller Replacement

Vietnam Shiprepair recently replaced an impeller and maintained a sea water pump at Cam Pha Anchorage. Here are the key steps:

- Inspection: We examined the pump for impeller damage, corrosion, and blockages.

- Isolation: Shut down the system and isolated the pump to ensure safety.

- Disassembly: Removed the pump casing to access the impeller.

- Impeller Replacement: Extracted the old impeller and installed a new one, adhering to IMO/IACS standards.

- Reassembly and Cleaning: Reassembled the pump, cleaned internal components, and checked seals.

- Testing: Conducted pressure and flow tests to verify performance and compliance.

This process restored the pump’s efficiency, meeting international safety norms.

Vietnam Shiprepair team providing marine services at Workshop

Vietnam Shiprepair team providing marine services at Workshop

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Services, including Sea Water Pump Repairing, across Vietnam:

- Cam Pha Anchorage: Ideal for efficient maintenance, as shown recently.

- Danang Port: A key hub for quick VietNam ShipRepair solutions.

- Nationwide Reach: We serve Nghi Son Port, Vung Tau, and all ports and anchorages. Explore Services.

- Mobile Operations: Our team brings tools directly to your vessel.

- Rapid Response: Fast deployment minimizes downtime.

Fully repaired sea water pump with new impeller by Vietnam Shiprepair at Cam Pha Anchorage.

Fully repaired sea water pump with new impeller by Vietnam Shiprepair at Cam Pha Anchorage.

Benefits of Choosing Vietnam Shiprepair for Sea Water Pump Repairing

Selecting Vietnam Shiprepair for Sea Water Pump Repairing ensures peace of mind. Our Marine Services save time with rapid maintenance, avoiding delays at Cam Pha Anchorage. Additionally, our cost-effective approach reduces expenses compared to full pump replacements, optimizing your budget. Moreover, our IACS-approved technicians deliver trusted results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IMO and IACS compliance, providing detailed reports for inspections. Contact us for efficient VietNam ShipRepair! Contact Us.

Vietnam Shiprepair’s Commitment to Excellence

Our maintenance process guarantees quality. We inspect the pump for issues. Then, we isolate and replace the impeller with precision. After that, we clean and reassemble. Finally, we test to ensure IMO/IACS compliance. Choose Vietnam Shiprepair for reliable Sea Water Pump Repairing.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

Auxiliary Overhauling at Quy Nhon Port

Auxiliary Overhauling at Quy Nhon Port – Expert Solutions by Vietnam Shiprepair

Is your bulk carrier’s generator engine requiring maintenance at Quy Nhon Port? Vietnam Shiprepair Co. provides expert Auxiliary Overhauling to ensure reliable power supply. July 01, 2025, we successfully overhauled a diesel generator engine for a bulk carrier at Quy Nhon Port. Moreover, our Marine Services and VietNam ShipRepair solutions extend to all ports and anchorages across Vietnam, including Danang Port, Nghi Son Port, Vung Tau, and beyond. Our work complies with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards—learn more at IMO Standards. Therefore, trust Vietnam Shiprepair for dependable marine services!

Vietnam Shiprepair team overhauling a generator engine at Quy Nhon Port

Vietnam Shiprepair team overhauling a generator engine at Quy Nhon Port

Importance of Generator Engines for Maritime Operations

Generator engines are critical for bulk carriers, powering essential systems like lighting, navigation, and cargo equipment at Quy Nhon Port. A reliable generator ensures uninterrupted operations, supporting crew safety and schedule adherence in challenging marine conditions. A failure can lead to blackouts, delaying cargo handling and risking equipment damage. Moreover, it impacts compliance with IMO and IACS efficiency standards. Vietnam Shiprepair’s Auxiliary Overhauling restores performance, ensuring your vessel remains operational and safe.

Significance of Regular AuxiliaryEngine Maintenance

Regular Auxiliary Overhauling is vital to prevent breakdowns and extend engine life. At Quy Nhon Port, where vessels face salt corrosion and heavy use, periodic maintenance reduces wear on components like fuel injectors and cooling systems. Additionally, it enhances fuel efficiency, lowering operational costs. Moreover, timely servicing meets IMO and IACS safety regulations, avoiding penalties and ensuring inspection readiness. Vietnam Shiprepair’s expertise ensures your generator remains reliable, minimizing unexpected downtime.

Basic Steps for Auxiliary Engine Overhauling

Vietnam Shiprepair recently performed Auxiliary Overhauling on a diesel generator at Quy Nhon Port. Here are the key steps:

- Inspection: We checked the engine for wear, leaks, and performance issues.

- Cleaning: Removed dirt and salt deposits from the cooling system and fuel lines.

- Component Replacement: Replaced worn parts, such as filters and seals, adhering to IMO/IACS standards.

- Lubrication: Applied high-quality oil to moving parts to reduce friction.

- Testing: Conducted load and pressure tests to verify efficiency and compliance.

This process restored the generator’s reliability, meeting international safety norms.

Vietnam Shiprepair’s Nationwide Marine Services Network

Delivers Marine Services, including Auxiliary Overhauling, across Vietnam:

- Quy Nhon Port: Ideal for efficient maintenance, as shown recently.

- Danang Port: A key hub for quick VietNam ShipRepair solutions.

- Nationwide Reach: We serve Nghi Son Port, Vung Tau, and all ports and anchorages. Explore Services.

- Mobile Operations: Our team brings tools directly to your vessel.

- Rapid Response: Fast deployment minimizes downtime.

Vietnam Shiprepair team providing marine services at Quy Nhon Port.

Benefits of Choosing Vietnam Shiprepair for Auxiliary Overhauling

Selecting Vietnam Shiprepair for Auxiliary Overhauling ensures confidence. Our Marine Services save time with rapid maintenance, avoiding delays at Quy Nhon Port. Additionally, our cost-effective approach reduces expenses compared to major repairs, optimizing your budget. Moreover, our IACS-approved technicians deliver trusted results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IMO and IACS compliance, providing detailed reports for inspections. Contact us for efficient VietNam ShipRepair! Contact Us.

Fully overhauled generator engine by Vietnam Shiprepair at Quy Nhon Port.

Fully overhauled generator engine by Vietnam Shiprepair at Quy Nhon Port.

Vietnam Shiprepair’s Commitment to Excellence

Our overhauling process guarantees quality. We inspect the engine for issues. Then, we clean and replace parts with precision. After that, we lubricate components. Finally, we test to ensure IMO/IACS compliance. Choose Vietnam Shiprepair for reliable Auxiliary Overhauling.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

- by Vietnam Ship Repair

- 0

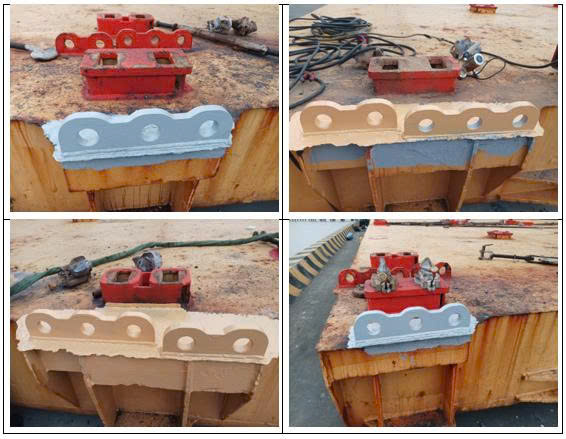

Generator Engine Re-winding and Overhauling at Vung Ang Port

Generator Engine Re-winding and Overhauling at Vung Ang Port – Expert Solutions by Vietnam Shiprepair

Is your bulk carrier’s generator engine failing at Vung Ang Port? Vietnam Shiprepair Co. provides expert Generator Engine Re-winding and Generator Engine Overhauling to restore power reliability. June 01, 2025, we successfully serviced a generator engine for a bulk carrier at Vung Ang Port. Moreover, our Main Engine Services and VietNam ShipRepair solutions extend to all ports and anchorages across Vietnam, including Danang Port, Nghi Son Port, Vung Tau, and beyond. Our work complies with International Maritime Organization (IMO) and International Association of Classification Societies (IACS) standards—learn more at IMO Standards. Therefore, trust Vietnam Shiprepair for dependable marine services!

Vietnam Shiprepair team re-winding a generator engine at Vung Ang Port.

Vietnam Shiprepair team re-winding a generator engine at Vung Ang Port.

Importance of Generator Engines for Maritime Operations

Generator engines are the backbone of maritime operations, powering lighting, navigation, and essential systems on bulk carriers at Vung Ang Port. A reliable generator ensures uninterrupted electricity, supporting crew safety and cargo handling in demanding conditions. A faulty generator, due to worn stator windings or poor maintenance, can lead to power outages, delaying schedules and risking equipment damage. Moreover, it violates IMO and IACS efficiency and safety standards. Vietnam Shiprepair’s Generator Engine Overhauling and Generator Engine Re-winding restore performance, ensuring compliance and operational continuity.

Vietnam Shiprepair’s Nationwide Main Engine Services Network

Delivers Main Engine Services, including Generator Engine Re-winding and Generator Engine Overhauling, across Vietnam:

- Vung Ang Port: Ideal for efficient repairs, as demonstrated recently.

- Danang Port: A key hub for quick VietNam ShipRepair solutions.

- Nationwide Reach: We serve Nghi Son Port, Vung Tau, and all ports and anchorages. Explore Services.

- Mobile Operations: Our team brings specialized tools to your vessel.

- Rapid Response: Fast deployment minimizes downtime.

Vietnam Shiprepair team performing generator engine overhauling at Workshop.

Vietnam Shiprepair team performing generator engine overhauling at Workshop.

Basic Steps for Generator Engine Re-winding and Overhauling

Vietnam Shiprepair recently re-wound and overhauled a generator engine at Vung Ang Port. Here are the essential steps:

- Inspection: We assessed the stator and other components for insulation damage or wear.

- Disassembly: Removed the stator and disconnected electrical connections safely.

- Re-winding: Stripped old windings, installed new copper coils, and applied insulation, adhering to IMO/IACS standards.

- Reassembly: Reinstalled the stator and reconnected the system with precision.

- Testing: Conducted voltage and load tests to ensure performance and compliance.

This process restored the generator’s efficiency, meeting international safety requirements.

Benefits of Choosing Vietnam Shiprepair for Generator Services

Selecting Vietnam Shiprepair for Generator Engine Re-winding and Generator Engine Overhauling ensures peace of mind. Our Main Engine Services save time with rapid repairs, avoiding delays at Vung Ang Port. Additionally, our cost-effective approach reduces expenses compared to full engine replacements, optimizing your budget. Moreover, our IACS-approved technicians deliver reliable results, enhancing vessel safety and reputation. With over 20 years of experience, Vietnam Shiprepair ensures IMO and IACS compliance, providing detailed reports for inspections. Contact us for efficient VietNam ShipRepair! Contact Us.

Fully overhauled generator engine by Vietnam Shiprepair at Vung Ang Port.

Fully overhauled generator engine by Vietnam Shiprepair at Vung Ang Port.

Vietnam Shiprepair’s Commitment to Excellence

Our process guarantees quality. We inspect the generator for faults. Then, we disassemble and re-wind with precision. After that, we reassemble and test. Finally, we ensure IMO/IACS compliance. Choose Vietnam Shiprepair for trusted Generator Engine Overhauling.

-

VIETNAMSHIPREPAIR repairs at Cai Mep Port.

-

VIETNAMSHIPREPAIR at Nha Trang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Quy Nhon Port and Anchorage.

-

VIETNAMSHIPREPAIR at Da Nang Port and Anchorage.

-

VIETNAMSHIPREPAIR at Son Duong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghi Son Port and Anchorage.

-

VIETNAMSHIPREPAIR at Nghe Tinh and Vissai Port and Anchorage.

-

VIETNAMSHIPREPAIR at Hai Phong Port and Anchorage.

-

VIETNAMSHIPREPAIR at Cai Lan Port and Anchorage.

Contact Vietnam Shiprepair

- Post Address: Tropic Garden, 66 Thao Dien, District 2, HCM City, Vietnam.

- Mobile/WhatsApp/WeChat: +84 869 677 769.

- Email: contact@vietnamshiprepair.net.

- Website: https://vietnamshiprepair.net.

Archives

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | 29 |

| 30 | 31 | |||||

Categories

- News (9)

- Project Updates (106)